Integrated insulation cushion slot paper

A technology of insulating slot paper and insulating pad, which is applied in laying solid insulation, shape/style/structure of winding insulation, and manufacturing motor generators, etc. To achieve the effect of reducing manual assembly, reasonable structure and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing (embodiment):

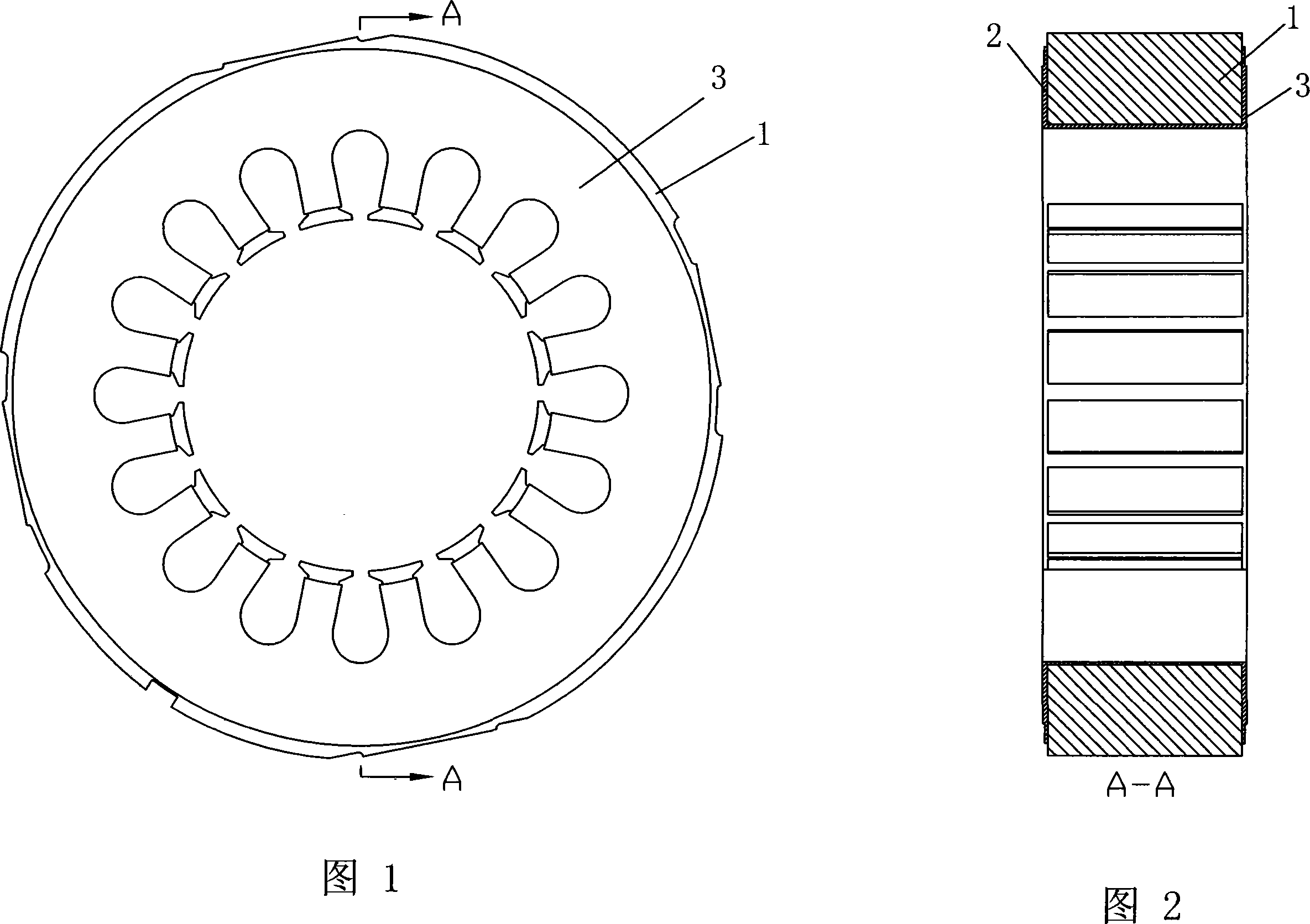

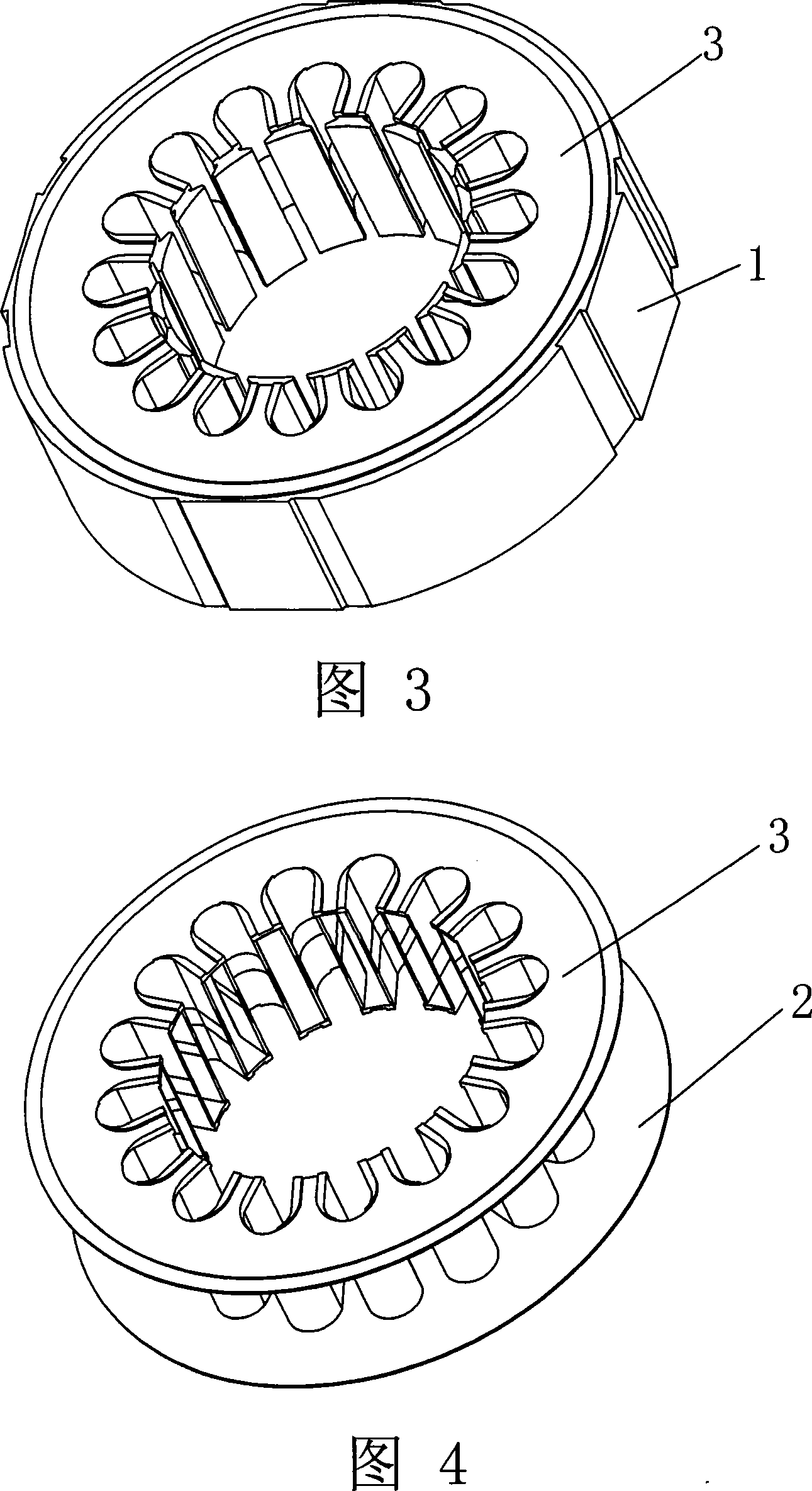

[0015] Referring to accompanying drawings 1-4, the present invention is composed of stator core lamination 1, left inner insulation slot paper nest 2, right inner insulation slot paper nest 3, left inner insulation slot paper nest 2 and right inner insulation slot paper The nesting 3 and the stator core lamination 1 are of an integrated structure.

[0016] The above-mentioned integrated structure can directly embed the stator core lamination 1 into the plastic howl machine for injection molding, the left inner insulation slot paper nesting 2, the right inner insulation slot paper nesting 3, and the stator iron core lamination 1 melt as one.

[0017] The injection temperature mentioned above is 270° C.; the injection pressure is 75 Bav; the injection time is 2 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com