Double-shaft hinge device

A technology of biaxial hinges and hinges, which is applied in the direction of hinges with pins, pivot connections, transmission systems, etc., can solve the problems of high manufacturing costs of hinge devices, and achieve the effect of cheap manufacturing costs and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Preferred embodiments for carrying out the present invention will be described below with reference to the drawings.

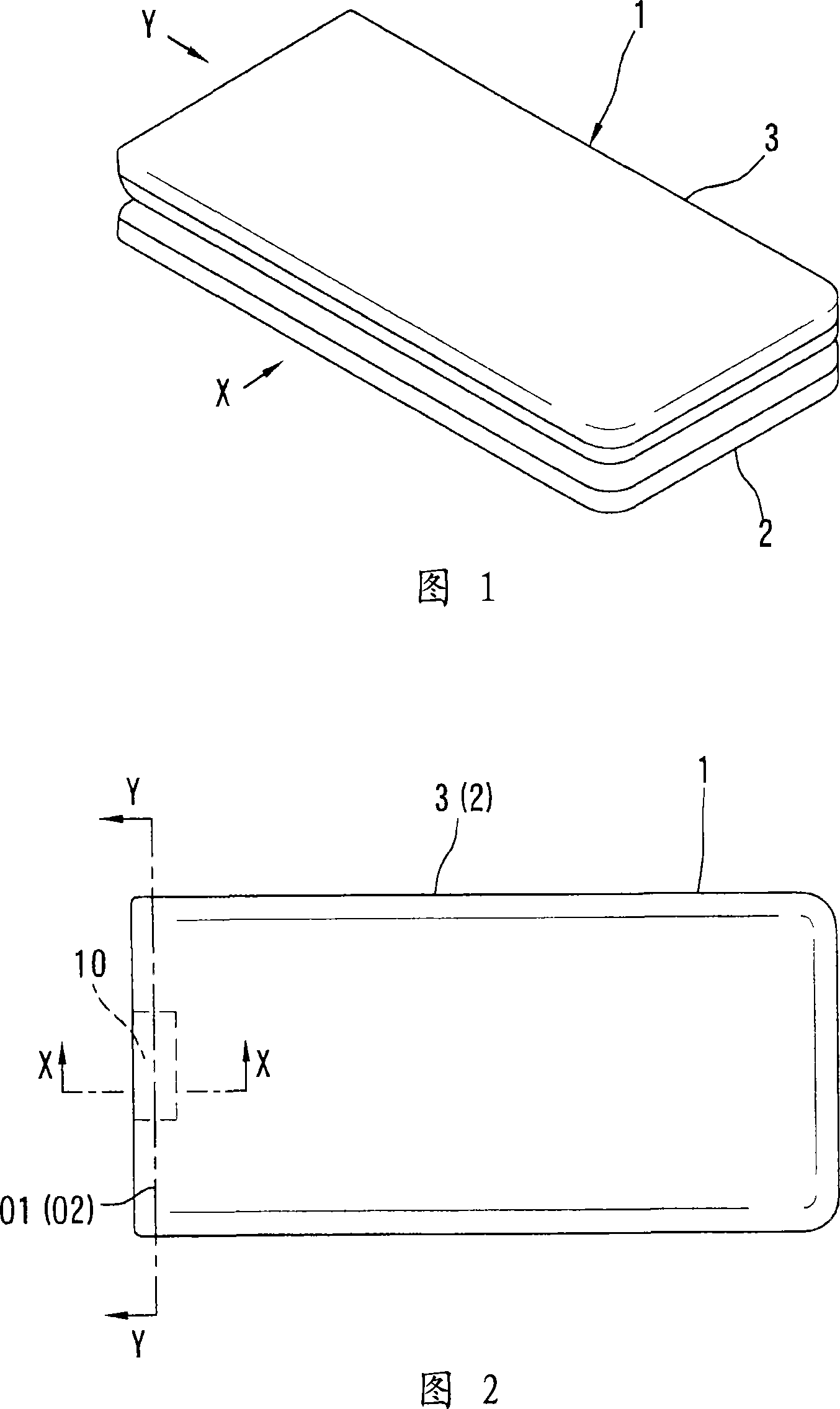

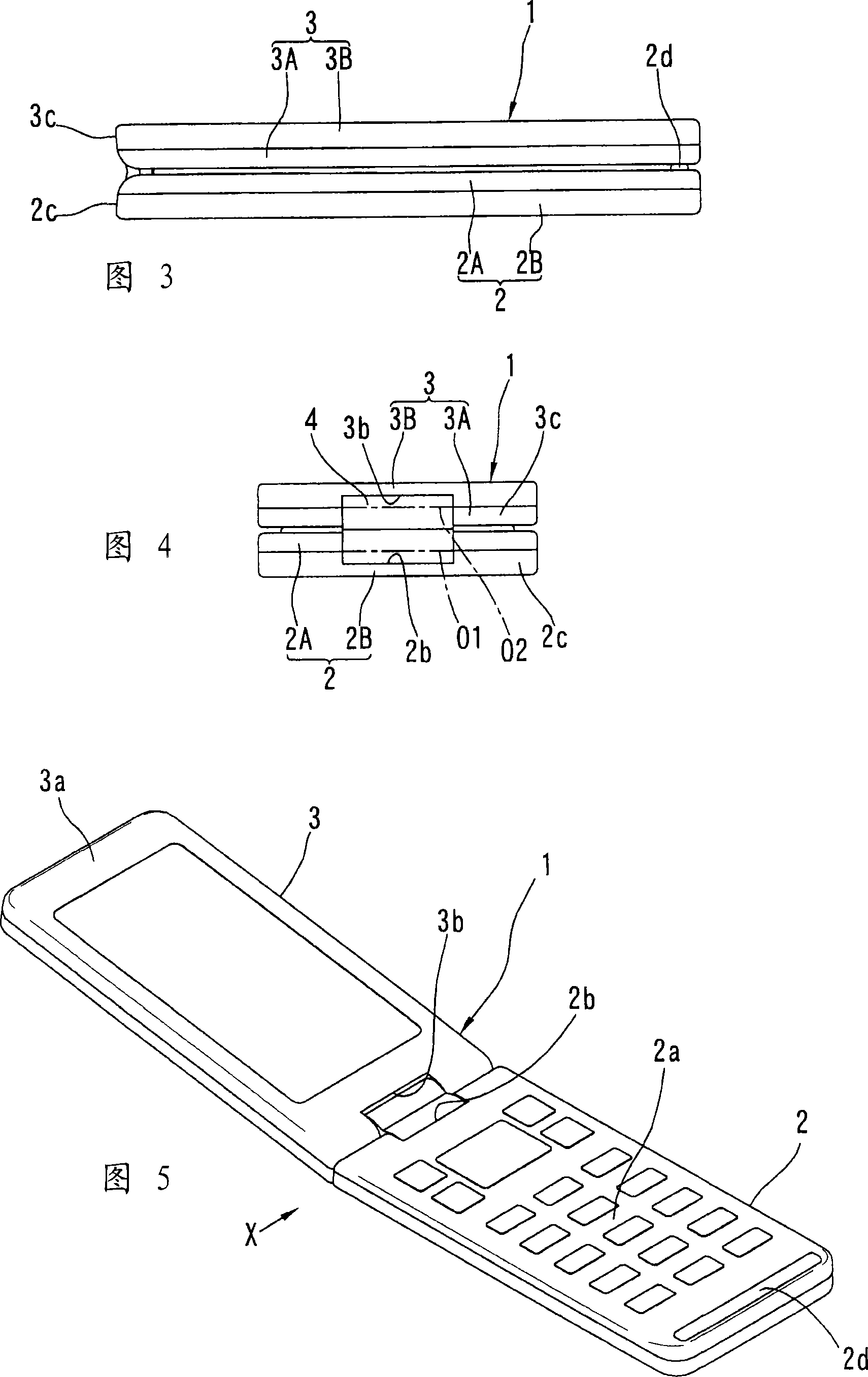

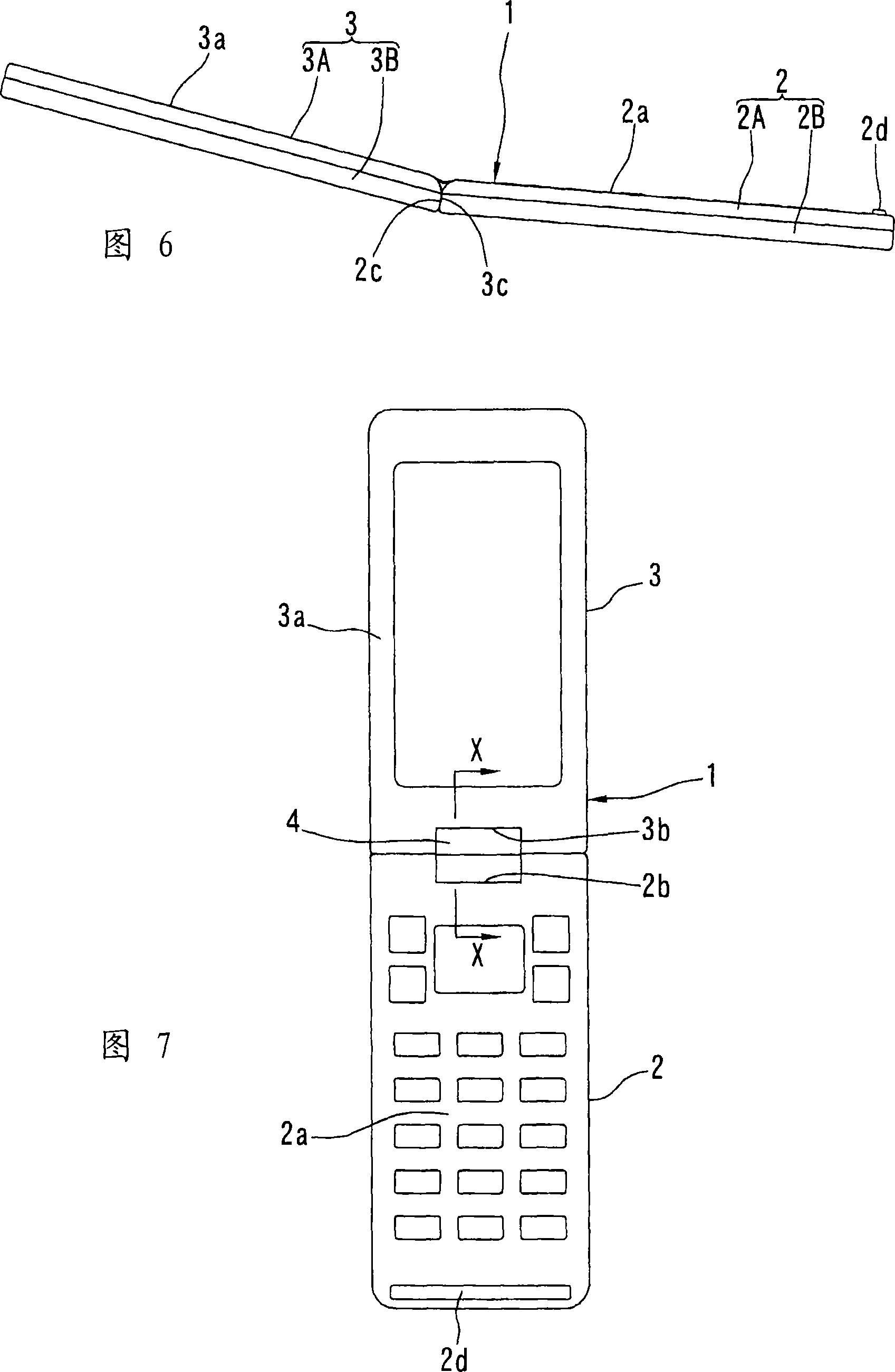

[0044] 1 to 11 show a mobile phone 1 using a hinge device 10 of the present invention. The mobile phone 1 includes a talking side housing 2 and a receiving side housing 3 . One end of the calling-side housing 2 and one end of the receiving-side housing 3 are connected by a hinge device 10 so as to be rotatable.

[0045] The communication-side housing 2 is composed of two half bodies 2A and 2B, and is formed in a relatively thin rectangular parallelepiped shape. As shown in FIGS. 8 to 11 , a mounting recess 2 b is formed at one end in the longitudinal direction of the front surface 2 a of the communication side housing 2 . The receiving side housing 3 is composed of two halves 3A, 3B, and is formed in a relatively thin rectangular parallelepiped shape. The top view shape of the receiving side frame 3 is substantially the same as the top view shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com