Dyeing waste water heat energy recovery method and recovery system

A technology for heat energy recovery and industrial wastewater, applied in heat recovery systems, heat transfer modification, heat exchange equipment, etc., can solve the problems of complex equipment technology, high operating costs, insufficient heat exchange capacity, etc., and achieve simple method and system composition. , The effect of improving work efficiency and energy saving effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

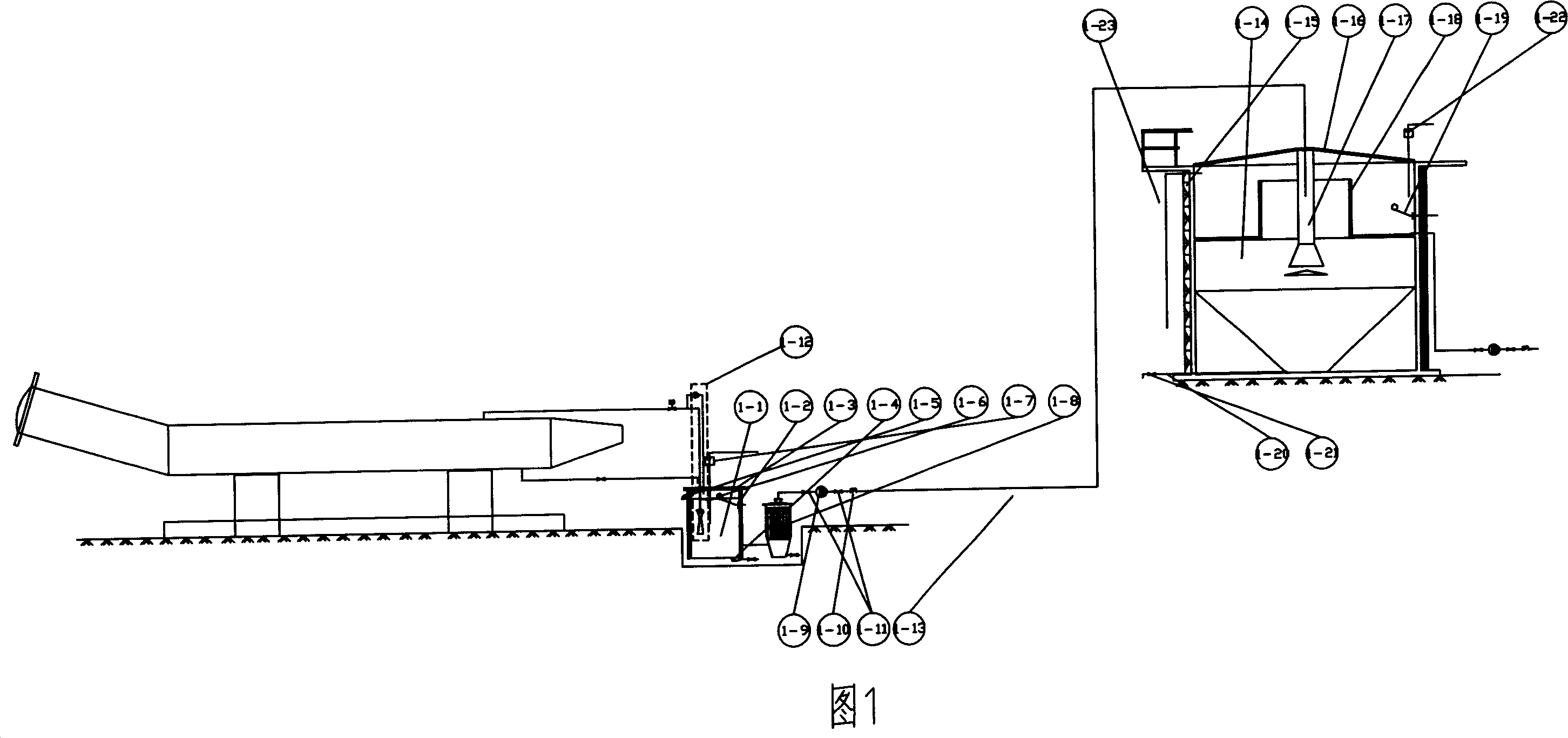

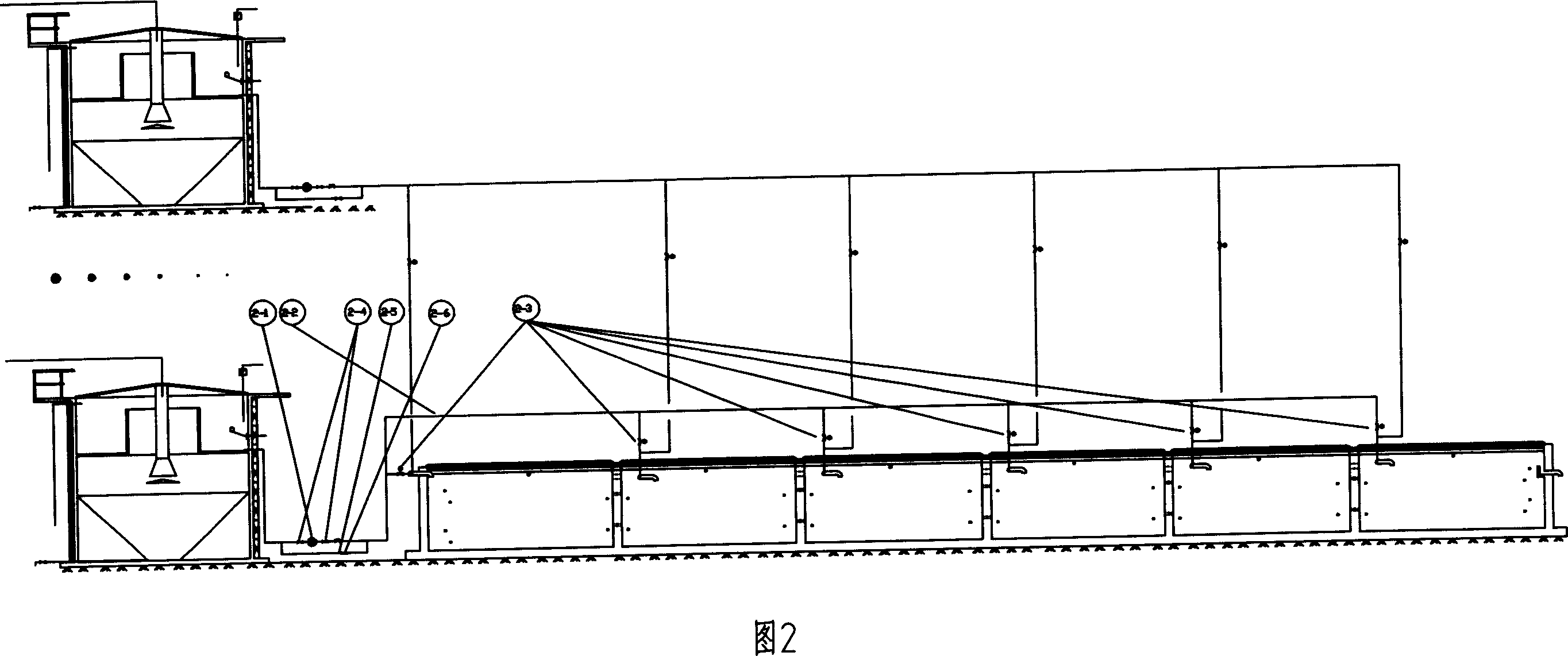

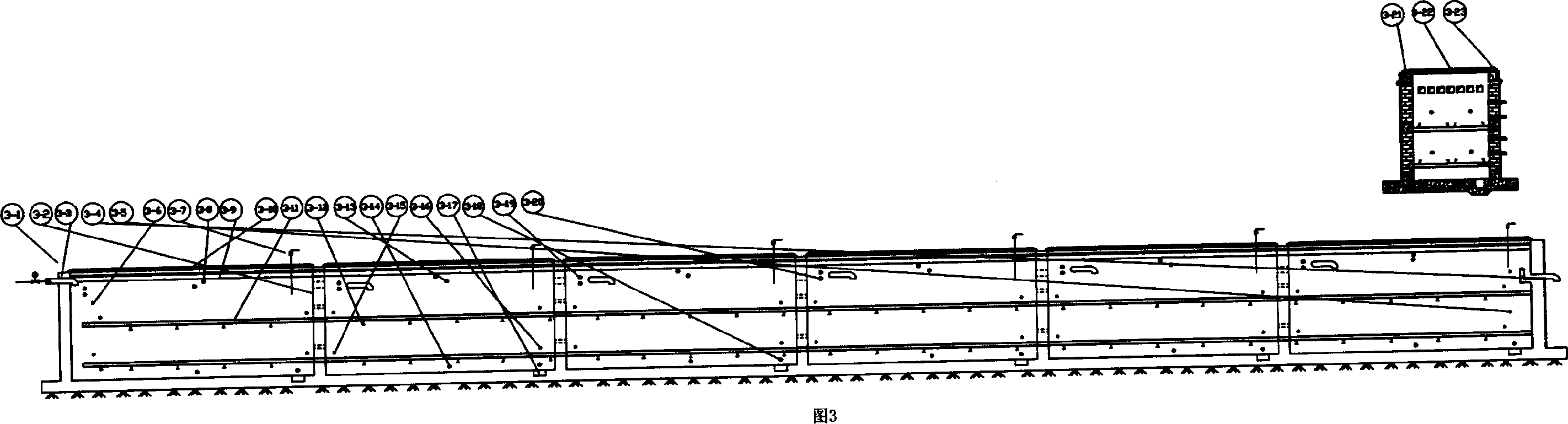

[0034] The method for recovering heat energy from waste water in the printing and dyeing industry of the present invention is as follows: separately collect hot sewage and / or waste hot steam at different temperatures, and transport and concentrate them directly or indirectly to a heat exchange unit consisting of at least two heat exchange units at different temperatures. In the heat exchanger, heat is exchanged with the tap water flowing through each heat exchange unit, and then the tap water obtained by the PLC control device is kept warm in different temperature sections, stored and distributed to the production machines required by each water use.

[0035] Before entering the heat exchange unit, the hot sewage at each temperature section is at least subjected to sewage treatment such as filtration, such as filtering fiber impurities; the hot sewage at each temperature section is at least collected in at least one heat preservation set before entering the heat exchange unit I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap