Method for preparing cyclohexanone-oxime from cyclohexanone ammoximation

A technology for cyclohexanone amidoxime and cyclohexanone oxime, which is applied in the field of preparing cyclohexanone oxime by ammoximation of cyclohexanone, can solve the problems of easy clogging of catalyst and poor separation effect, and achieves the effect of solving the separation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

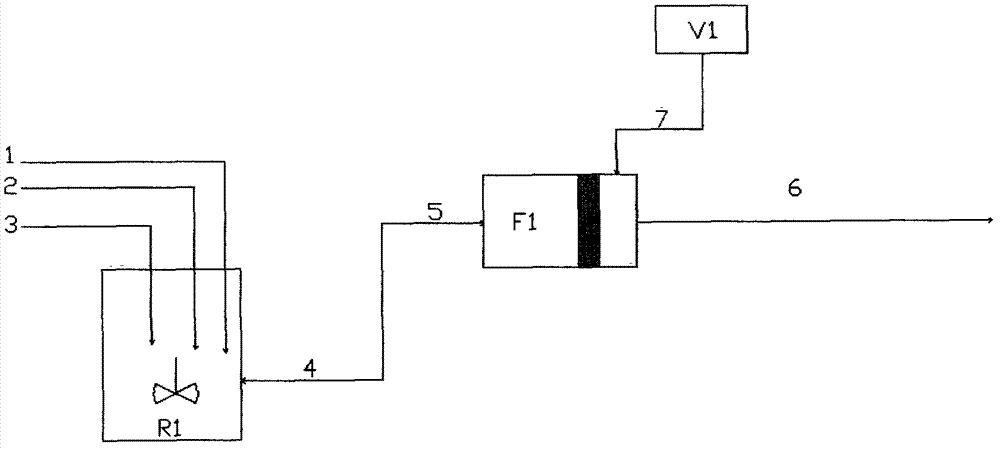

[0053] For the reaction process, see figure 1 , the specific feed parameters and material settlement conditions are as follows:

[0054] Cyclohexanone = 160.0 g / h

[0055] tert-butanol = 781.0 g / h

[0056] 30% by weight hydrogen peroxide = 194.3 g / h

[0057] Liquid ammonia = 60.9 g / h

[0058] Titanium silicon molecular sieve concentration = 2.0% by weight

[0059] The average residence time of materials in the reactor is 75 minutes, the reaction temperature is maintained at 83±1°C through jacket heat exchange, and the reaction pressure is maintained at 0.3MPa.

[0060] Maintain the temperature of the reaction product material entering the settler at 70°C, filter in a sintered filter, and backwash once every 20 seconds.

[0061] Its reaction result is as follows:

[0062] Cyclohexanone conversion rate: 97.5%

[0063] Conversion rate of hydrogen peroxide: 100%

[0064] Reaction selectivity based on cyclohexanone: 98.5%

[0065] Effective utilization rate of hydrogen per...

Embodiment 2

[0069] For the reaction process, see figure 1 , the specific feed parameters and material settlement conditions are as follows:

[0070] Cyclohexanone = 196.0 g / h

[0071] tert-butanol = 850.0 g / h

[0072] 30% by weight hydrogen peroxide = 249.3 g / h

[0073] Liquid ammonia = 51.0 g / h

[0074] Titanium silicon molecular sieve concentration = 2.5% by weight

[0075] The average residence time of materials in the reactor is 80 minutes, the reaction temperature is maintained at 75±1°C through jacket heat exchange, and the reaction pressure is maintained at 0.4MPa. The temperature of the reaction product material entering the sintered filter was maintained at 60° C., and the sintered filter was backwashed every 30 seconds.

[0076] The resulting reaction is as follows:

[0077] Cyclohexanone conversion rate: 96.3%

[0078] Conversion rate of hydrogen peroxide: 98.0%

[0079] Reaction selectivity based on cyclohexanone: 97.5%

[0080] Effective utilization rate of hydrogen ...

Embodiment 3

[0084] For the reaction process, see figure 1 , the specific feed parameters and material settlement conditions are as follows:

[0085] Cyclohexanone = 245.0 g / h

[0086] tert-butanol = 980.0 g / h

[0087] 30% by weight hydrogen peroxide = 311.7 g / h

[0088] Liquid ammonia = 85.0 g / h

[0089] Titanium silicon molecular sieve concentration = 4.0% by weight

[0090] The average residence time of materials in the reactor is 78 minutes, the reaction temperature is maintained at 88±1°C through jacket heat exchange, and the reaction pressure is maintained at 0.3MPa. Maintain the temperature of the reaction product material entering the sintered filter at 85° C., and backwash once every 20 seconds.

[0091] Cyclohexanone conversion rate: 98.5%

[0092] Conversion rate of hydrogen peroxide: 100%

[0093] Reaction selectivity based on cyclohexanone: 97.6%

[0094] Effective utilization rate of hydrogen peroxide: 87.4%

[0095] Yield of cyclohexanone oxime: 96.1%

[0096] Tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com