Apparatus for weighing liquid in a bottle, in particular a pharmaceutical bottle

A device and liquid technology, applied in the field of equipment for measuring the weight of liquid in a bottle, can solve problems such as disadvantages and achieve the effect of overcoming time constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

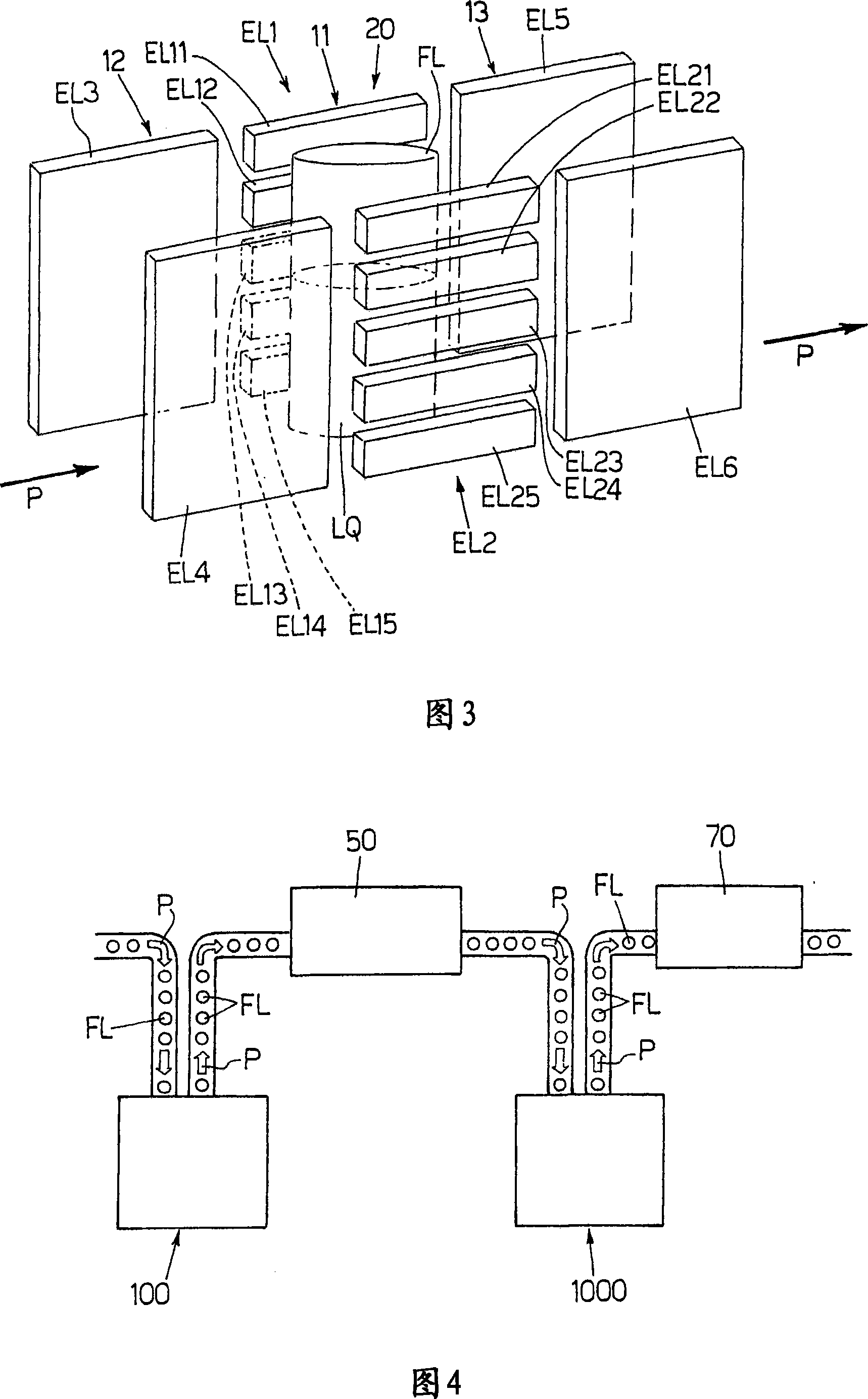

[0044] It is the object of the present invention to measure liquids using capacitive technology, which requires a special measuring unit 10 as shown in FIG. 2 by way of non-limiting example.

[0045] Bottles FL1 , FL2 , FL3 partially filled with liquid (empty in the case of a simple tare measurement) are fed through the measuring unit 10 .

[0046] The measuring unit 10 in FIG. 2 comprises an actual measuring part 11 (in the center of FIG. 2 ) which is preceded by a first guard part 12 and followed by a second guard part 13 which is located in the first guard. Partially along the downstream position in the direction of travel of the path P, the direction of travel is indicated by the arrow F.

[0047] The measuring section 11 in turn comprises two electrodes EL1 , EL2 located on opposite sides of the traveling bottles FL1 , FL2 , FL3 .

[0048] Each guard portion 12 and 13 comprises a pair of electrodes EL3, EL4 and EL5, EL6 which are held at the same potential as the adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com