Thin type CD-ROM drive tray structure

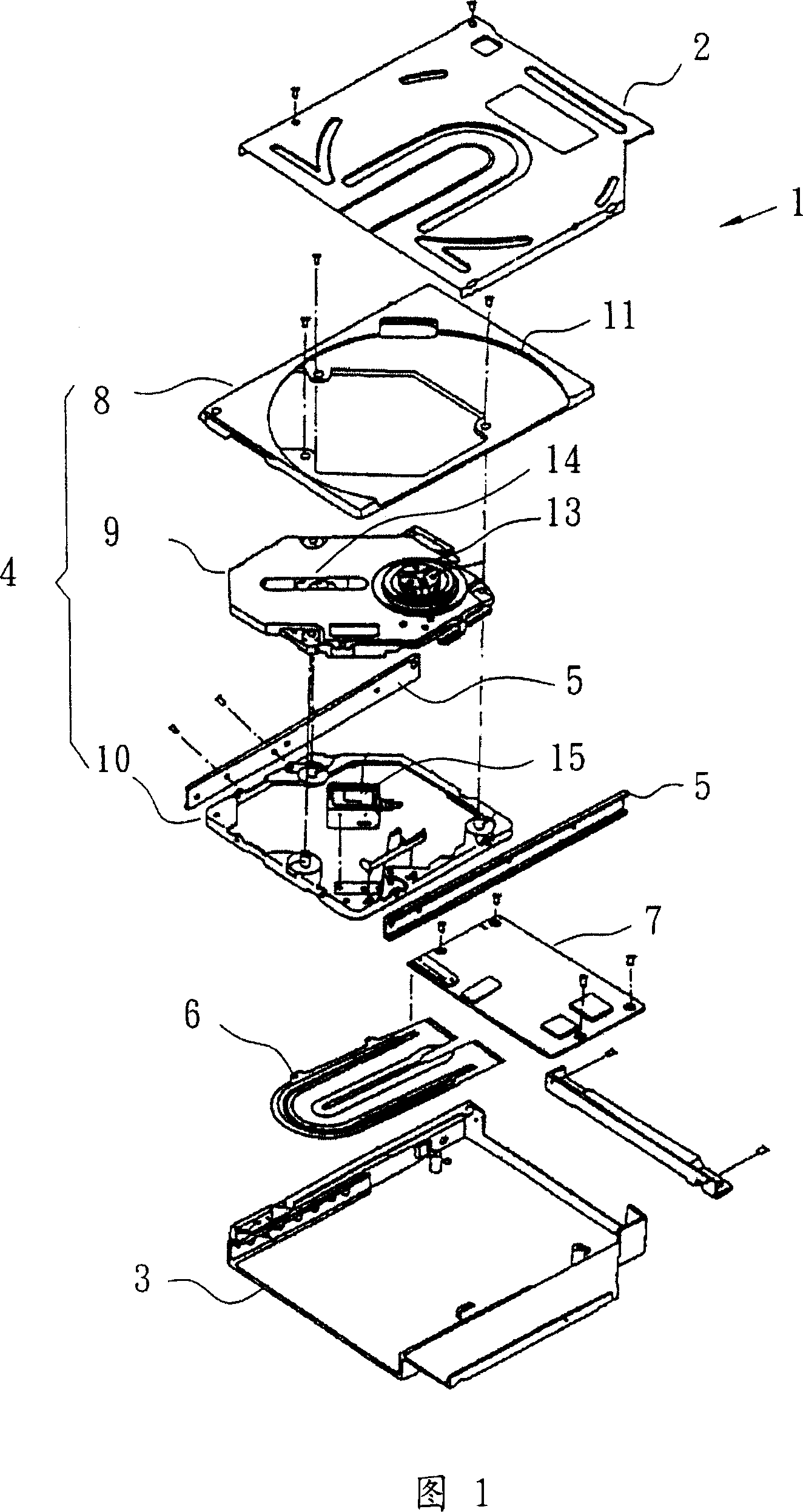

A technology for trays and optical drives, which is applied in the direction of record carrier structural parts, instruments, data recording, etc., can solve the problems of time-consuming manufacturing and assembly, high cost, and many components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical means adopted by the present invention to achieve the above-mentioned purpose and its effects are described as follows with reference to preferred embodiments and accompanying drawings.

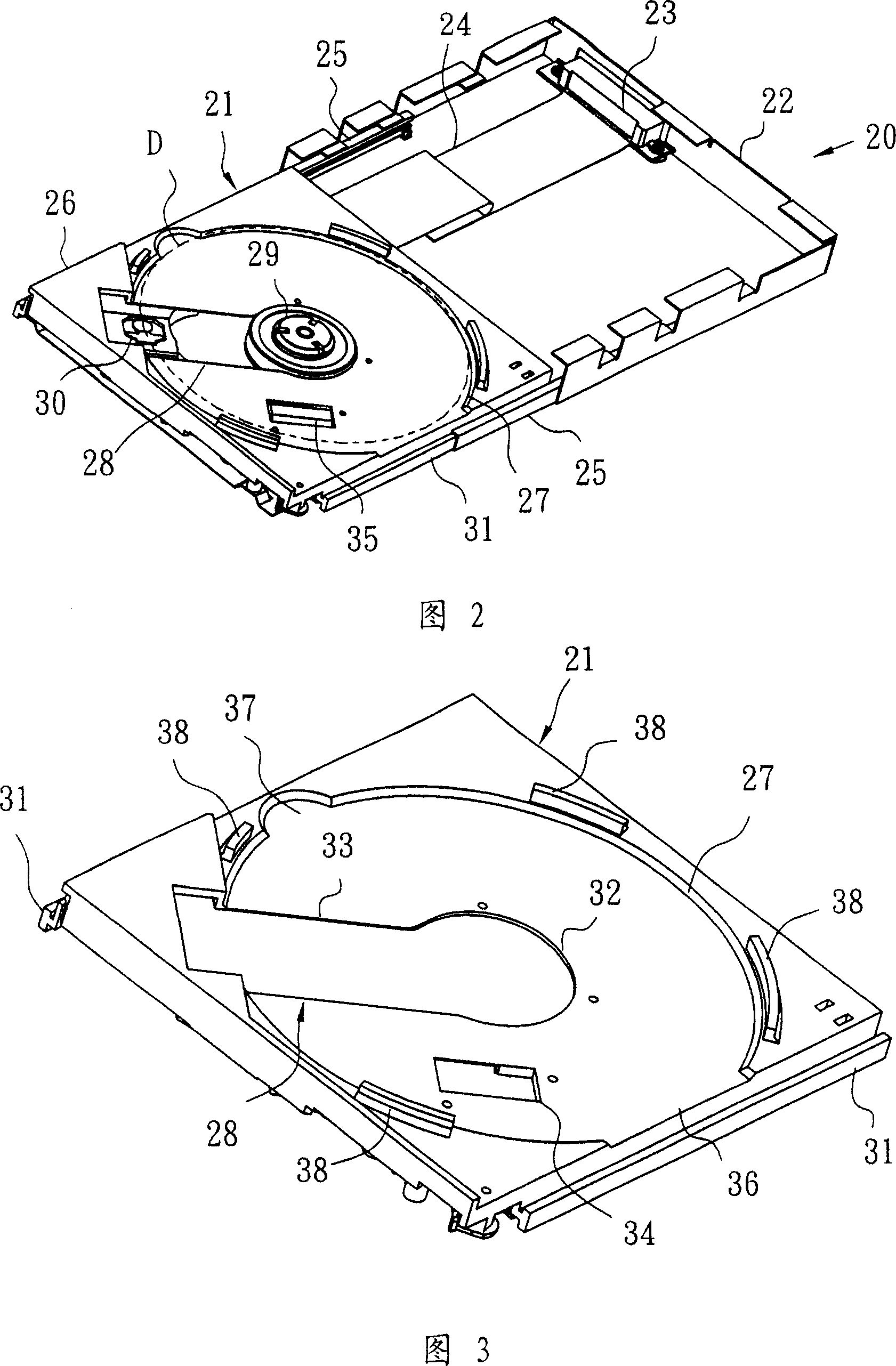

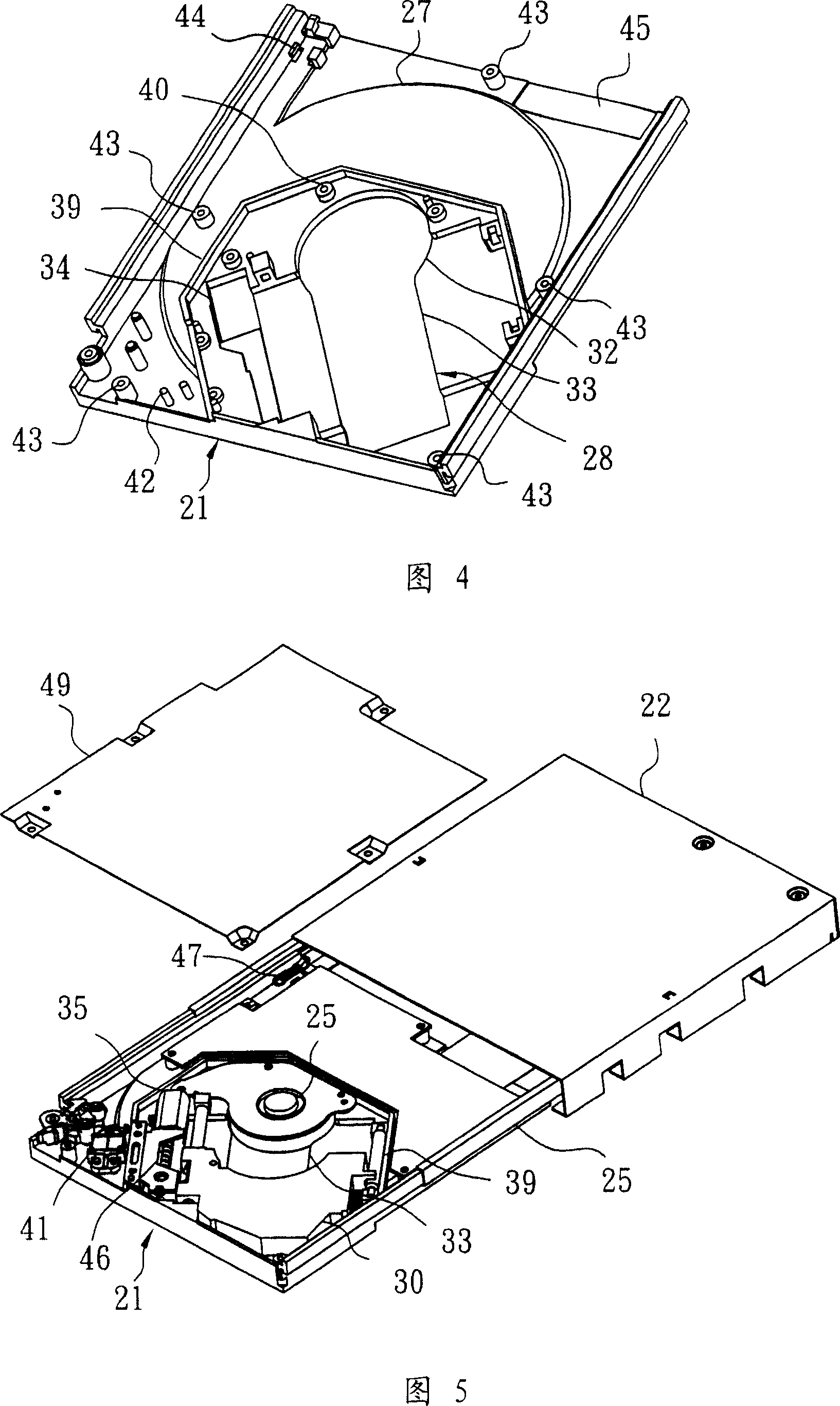

[0016] Referring to FIG. 2 , FIG. 2 is an internal structure of a thin optical drive 20 using the tray 21 of the present invention. The thin optical drive 20 includes a tray 21 , a casing 22 , a connector 23 , a cable 24 , a guide rail 25 and the like. The hollow interior mainly composed of the housing 22 accommodates the tray 21. The rear end of the tray 21 is connected to the cable 24, and the other end of the cable 24 is connected to the connector 23 provided at the rear end of the housing 22. The tray 21 is supported by guide rails 25 on both sides. , can slide in and out of the casing 22 of the slim optical drive 20 .

[0017] Wherein, the tray 21 is basically a body 26 of a rectangular flat body, and a nearly circular bearing groove 27 is recessed in the center, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com