Thin type CD-ROM drive tray structure

A tray and optical drive technology, which is applied to record carrier structural parts, instruments, data recording, etc., can solve the problems of time-consuming manufacturing and assembly, high cost, and many components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical means and effects adopted by the present invention to achieve the above objects are described below with reference to the preferred embodiments and the accompanying drawings.

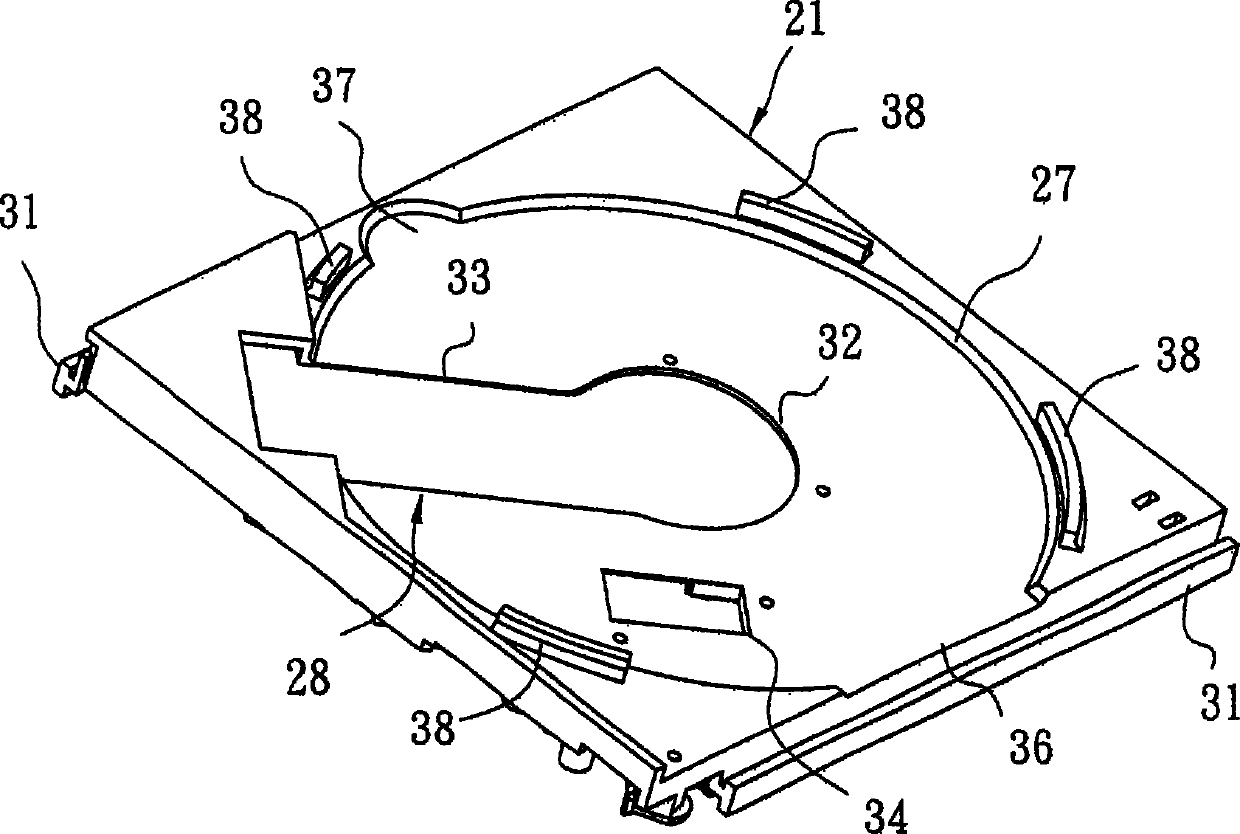

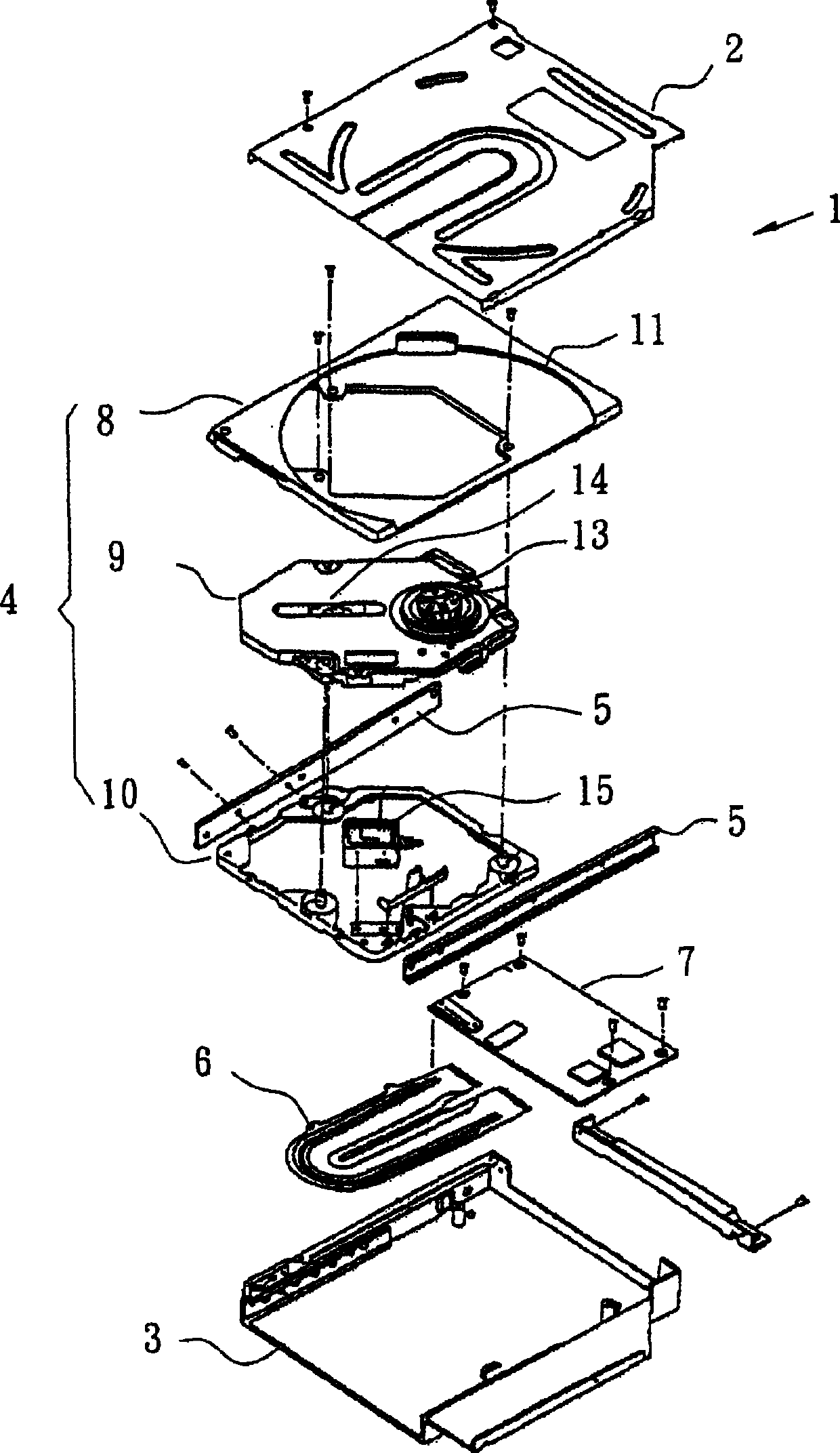

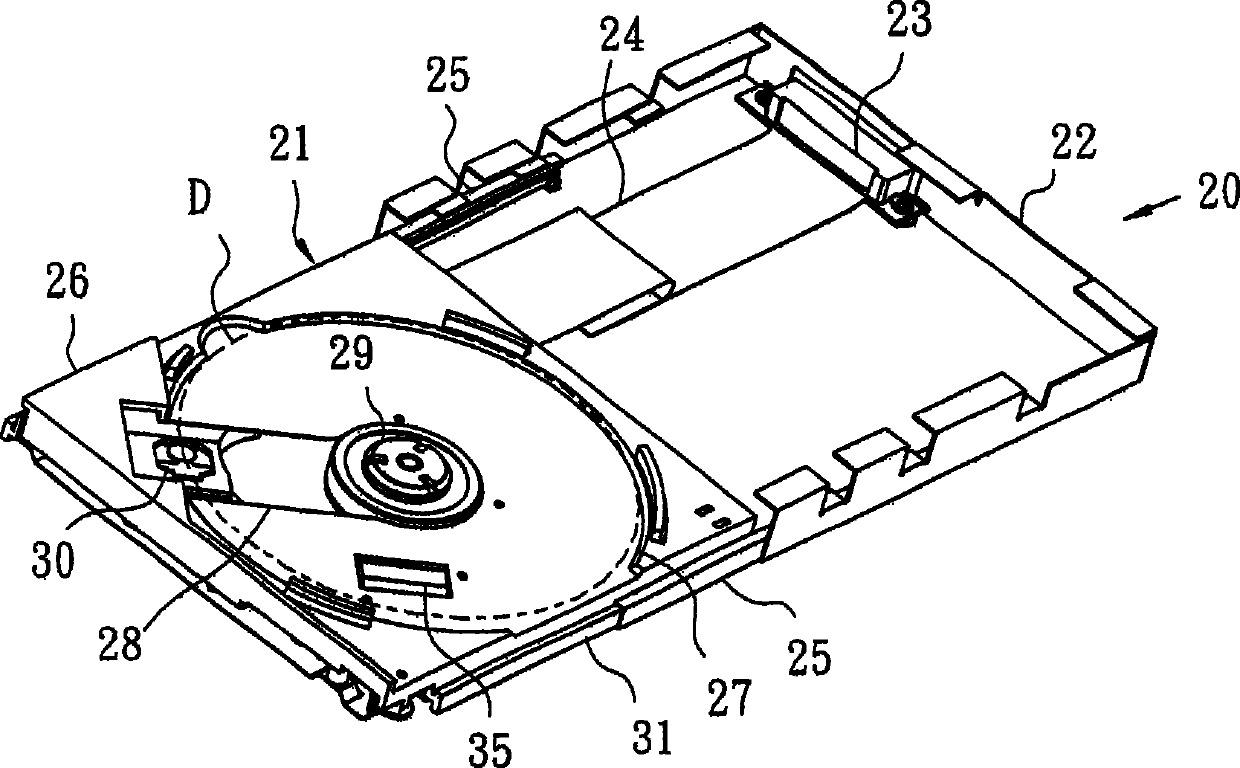

[0016] refer to figure 2 , figure 2 The internal structure of the tray 21 of the present invention is used for a thin optical drive 20 . The thin optical drive 20 includes a tray 21 , a casing 22 , a connector 23 , a cable 24 , a guide rail 25 and the like. The hollow interior mainly composed of the casing 22 accommodates the tray 21 , the rear end of the tray 21 is connected to the cable 24 , and the other end of the cable 24 is connected to the connector 23 provided at the rear end of the casing 22 , and the tray 21 is supported by the guide rails 25 on both sides. , the casing 22 of the thin optical drive 20 can be slid in and out.

[0017] The tray 21 is basically a rectangular flat body 26 with a nearly circular bearing slot 27 recessed in the center, a configuration hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com