Dredger clamping safety device

A safety device and excavator technology, applied in the direction of earth mover/shovel, construction, etc., can solve problems such as safety accidents, inability to fix bucket 200, bucket 200 falling, etc., to prevent safety accidents and separate operations. Easy and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0027] 5 to 9 show a first embodiment of the present invention.

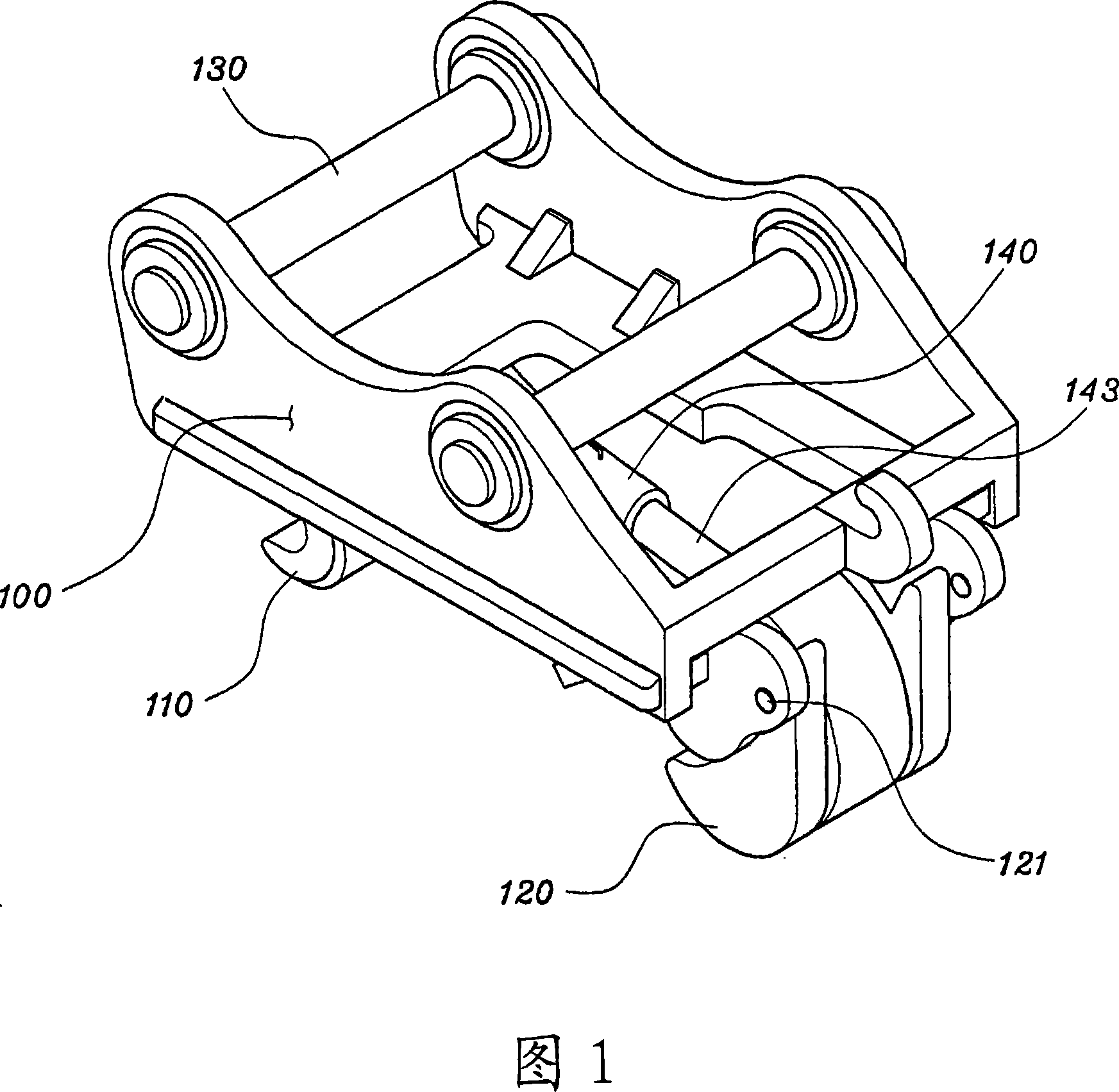

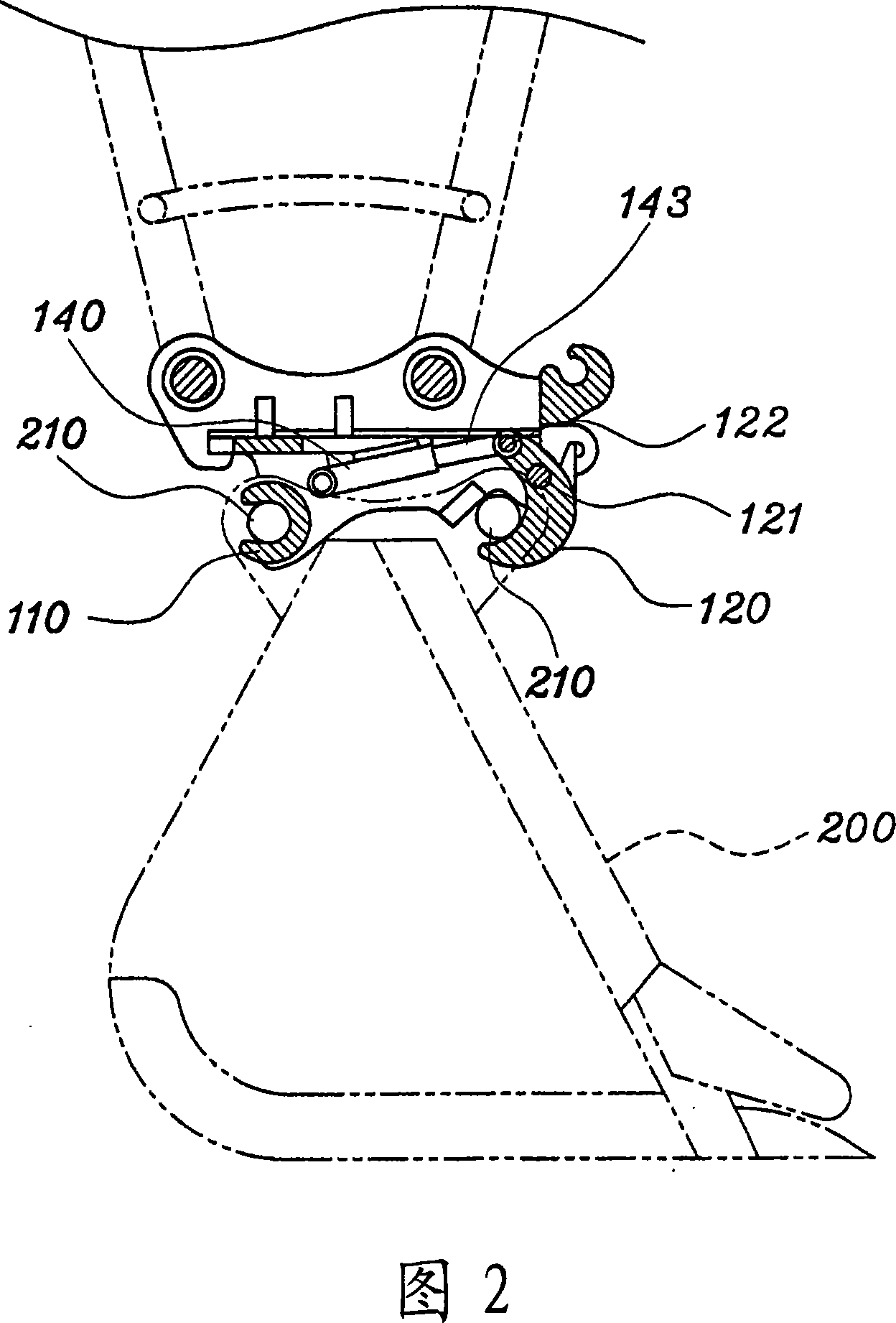

[0028] As shown in Figures 5 to 9, the excavator gripper of the first embodiment of the present invention is composed of the following parts: the connecting body 100 installed on the excavator arm and the bucket cylinder; installed on one side of the connecting body 100 , and the fixed hook 110 combined with the fixed pin 210 on one side of the above-mentioned bucket 200; the rotating hook 120, which is combined with the other side of the above-mentioned connecting body 100, and can freely rotate around the first hinge shaft 121. The rotating hook 120 is configured on the fixed pin 210 on the other side of the above-mentioned bucket 200; the cylinder 140 is installed on the above-mentioned connecting body 100 and the rotating hook 120, and the above-mentioned rotating hook 120 is connected to the second hinge shaft 14 by its cylinder 140. Rotate as the center, thereby fixing the fixing pin 210 on the other side ...

no. 2 example

[0045] On the other hand, in order to achieve the object of the present invention, a clamper safety device different from the above-mentioned embodiments as shown in FIGS. 10 to 12 is provided.

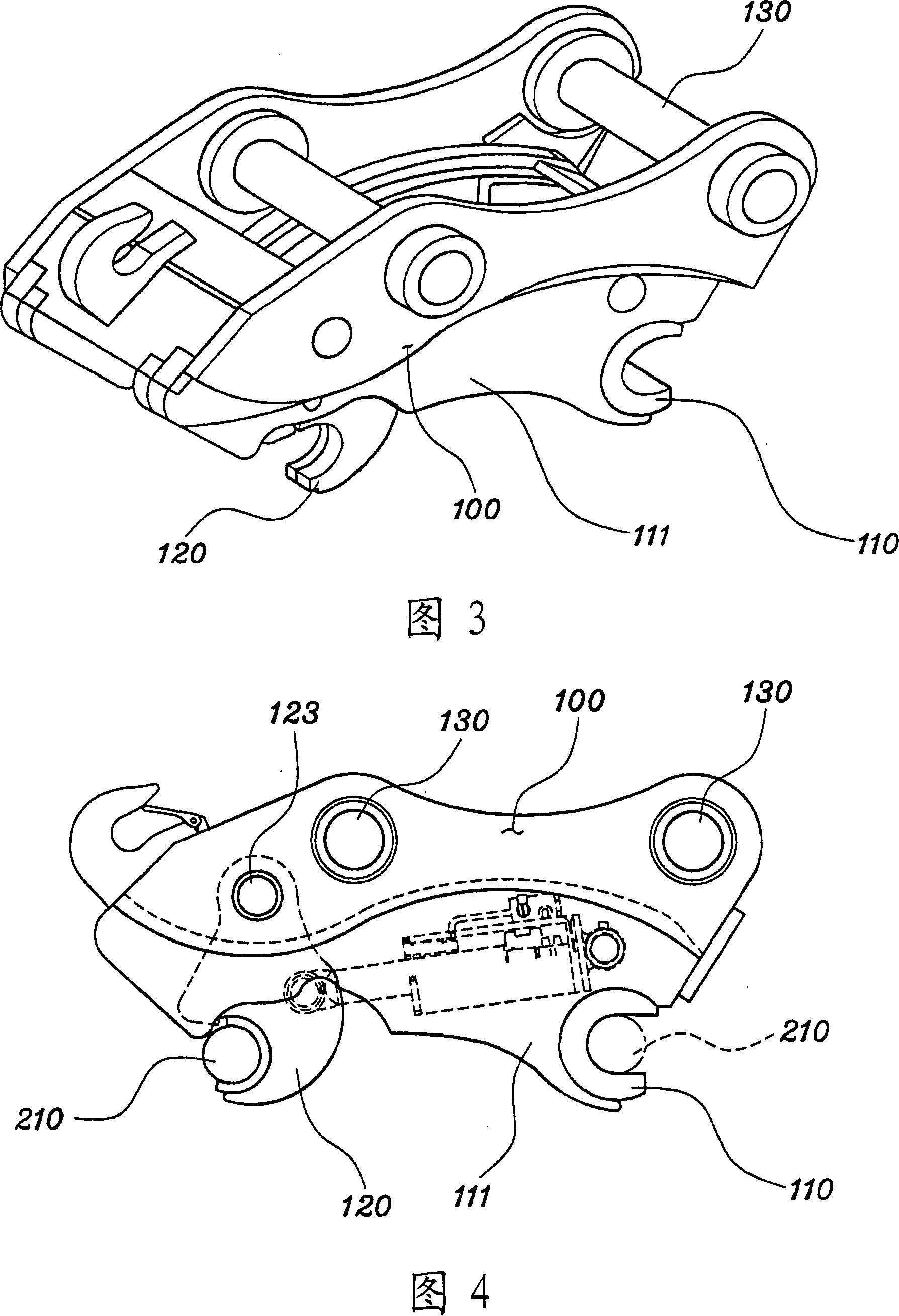

[0046] Fig. 10 is a schematic front view of the clamper safety device. The present invention is configured such that the excavator clamper includes two sides that are hinged on the front end of the excavator arm through a connecting pin 130 and installed to be spaced apart from each other. The connecting body 100; the hook support parts 111 on both sides, which are formed at the lower part of the above-mentioned connecting body 100, and fix the fixed hook 110 in such a way that the fixed hook 110 is inserted into the fixed pin 210 on one side of the bucket. Formed on the lower side of the hook support portion 111; the rotating hook 120 is freely rotatably coupled to the connecting body 100 through the hinge shaft 123, and is inserted into the fixing pin 210 on the other side of the sup...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap