Pressure control valve

A pressure control and pressure technology, which is applied in the field of pressure control valves of supercritical refrigeration cycles, can solve the problems of increasing the enclosed gas space, reducing equipment durability, and increasing discharge temperature, and achieves restraint of large-scale, restraint and high cost. , the effect of reducing the fluctuation of the control pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

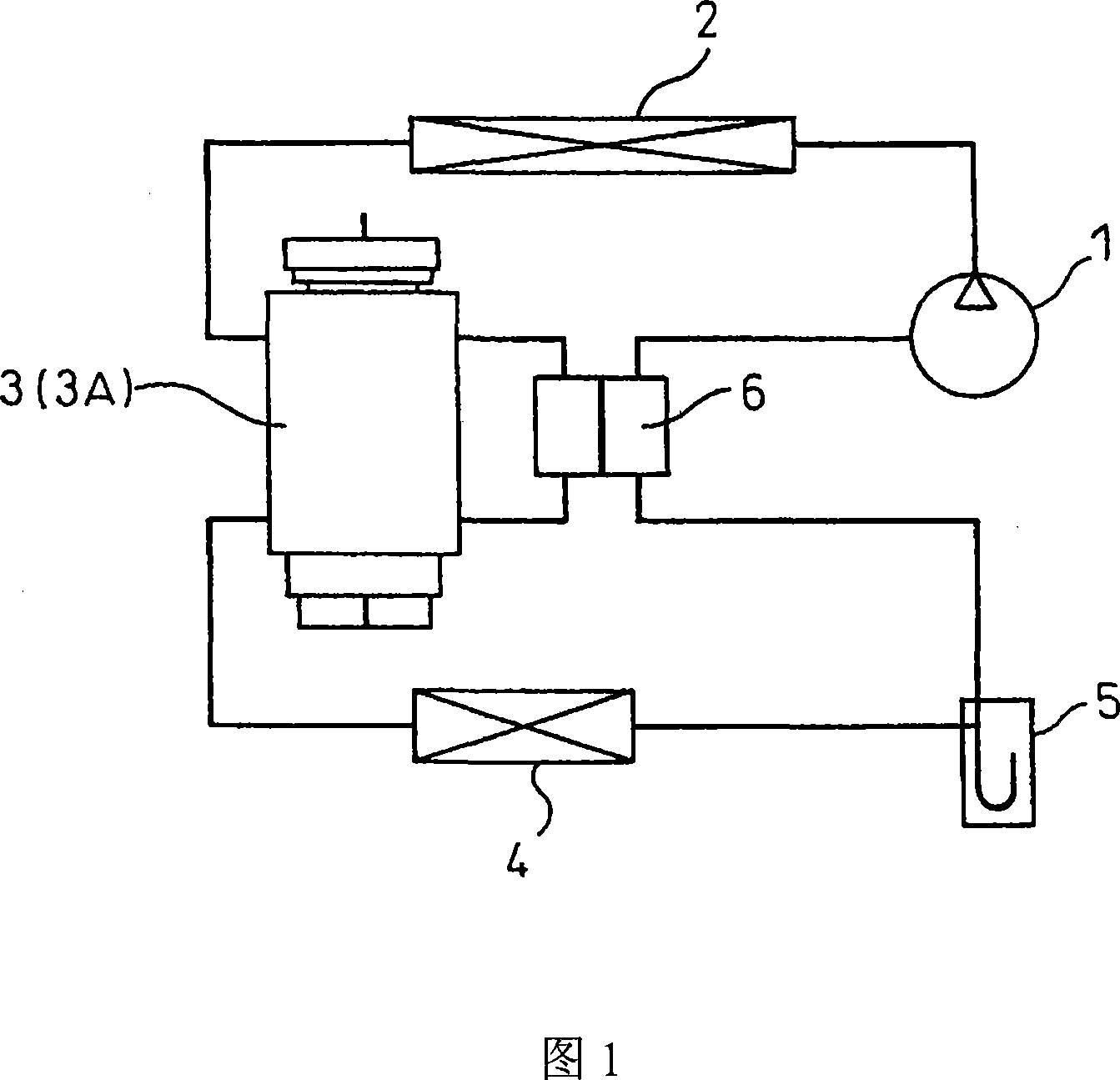

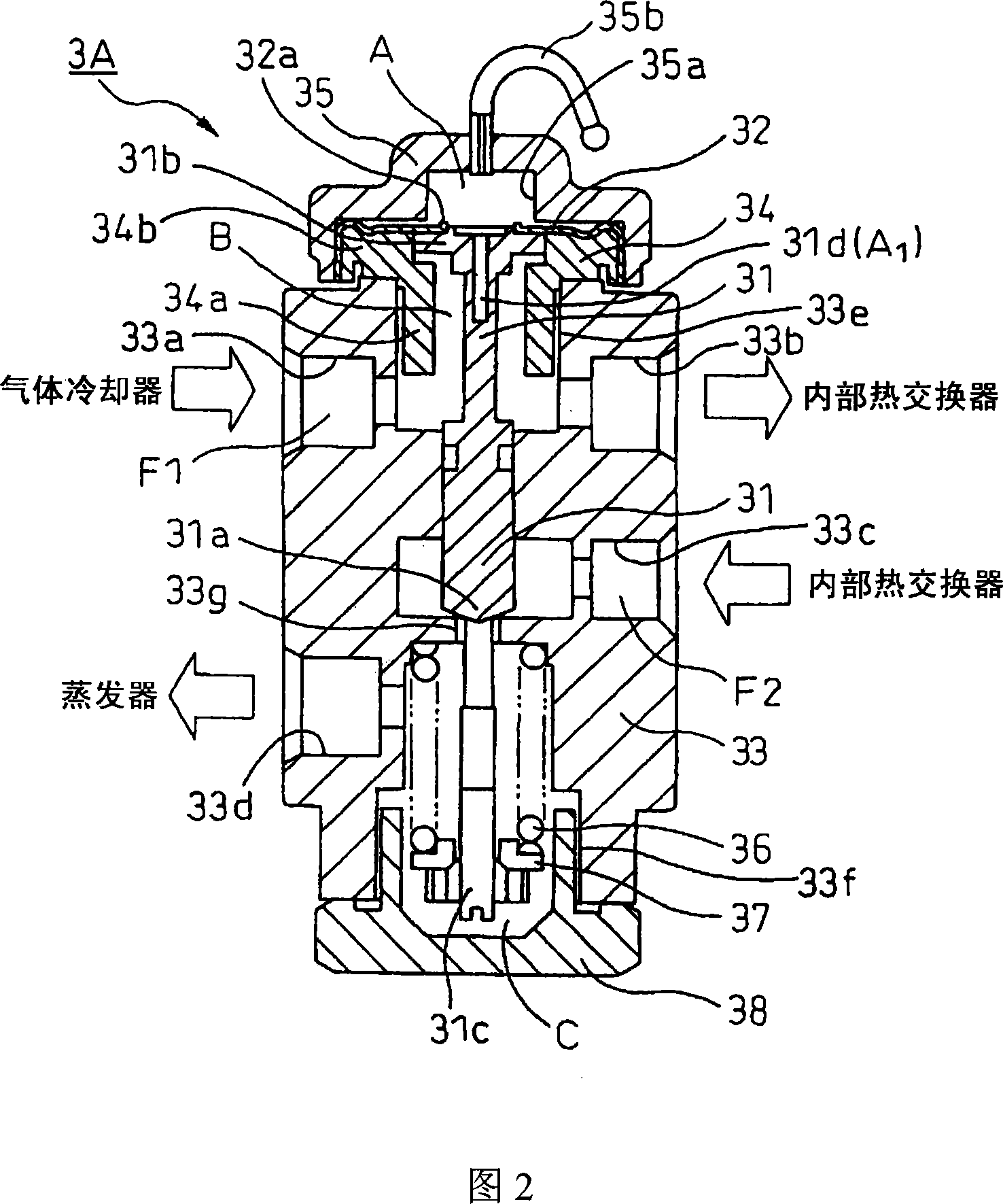

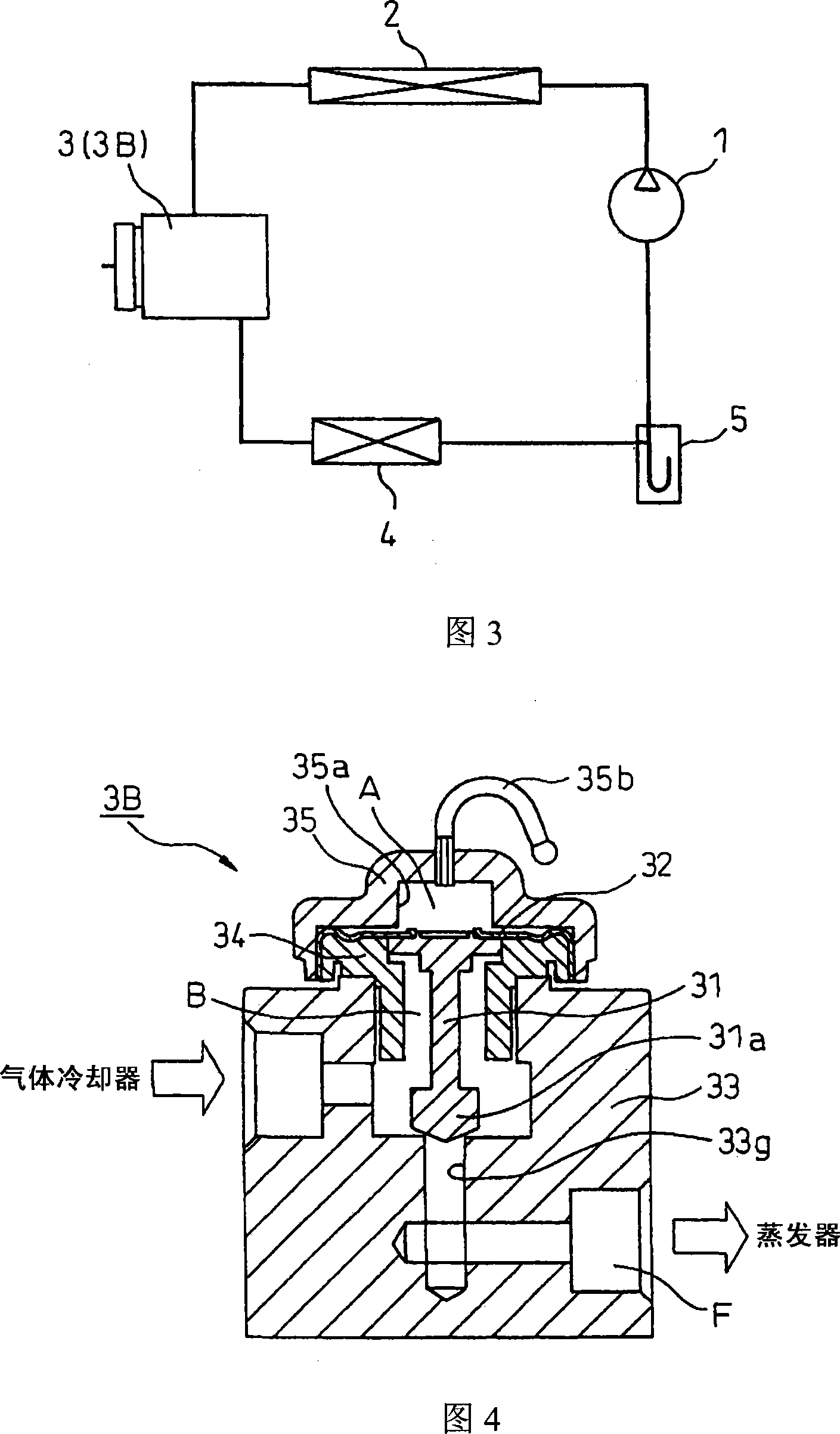

[0039] Next, a pressure control valve according to an embodiment of the present invention will be described with reference to the drawings. Figure 1 is for CO with internal heat exchanger 2 Fig. 2 is a diagram illustrating a refrigeration cycle (supercritical refrigeration cycle) in which refrigerant circulates. Fig. 2 is a pressure control valve according to a first embodiment of the present invention applied to the refrigeration cycle shown in Fig. 1 . In Figure 1, symbol 1 is inhaled CO 2 A compressor that compresses the refrigerant, and reference numeral 2 is a gas cooler (radiator) that cools the refrigerant compressed by the compressor 1 .

[0040] Reference numeral 3 is a pressure control valve (expansion valve) of this embodiment. The pressure control valve 3 has the CO 2 The temperature-sensing part (closed space) A in which the gas is enclosed controls the pressure of the refrigerant at the outlet side of the gas cooler 2 according to the temperature of the refrig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap