Liquid crystal substrate bonding system

A technology of liquid crystal substrates and substrates, which is applied in the directions of optics, instruments, electrical components, etc., can solve problems such as image quality degradation, poor movement, disturbed air, etc., and achieve the effect of improving coating and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, an embodiment of the liquid crystal panel assembly system of the present invention will be described with reference to the drawings.

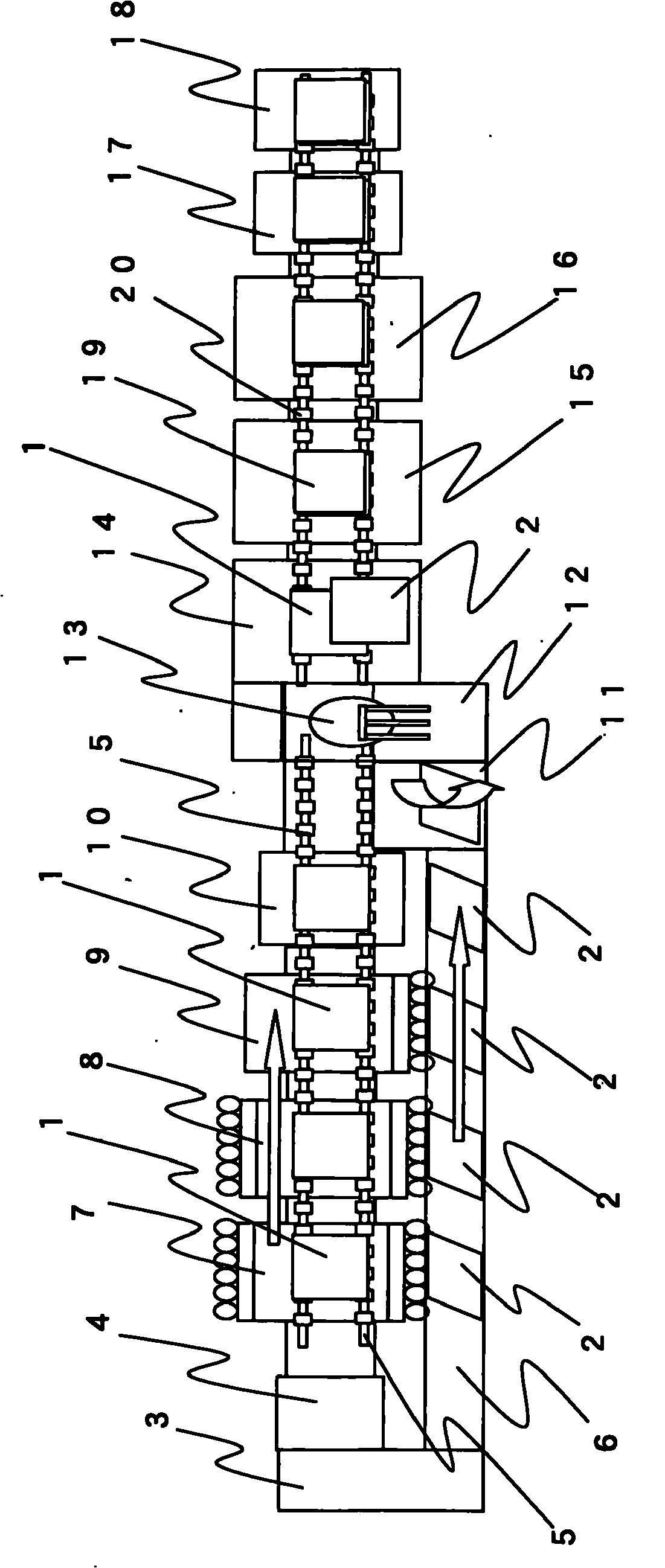

[0027] figure 1 It is a plan view showing the overall configuration of the liquid crystal panel assembly system of the present invention, 1 is the lower substrate, 2 is the upper substrate, 3 is the substrate carrying robot, 4 is the alignment mechanism, 5 is the first conveying line (main line), 6 is the second 2nd conveying line (secondary line), 7 is a paste coating machine (seal dispenser), 8 is a coating machine for short-circuit electrode formation, 9 is a liquid crystal dropping device, 10 is a first inspection room, and 11 is a substrate inversion device , 12 is the transmission room, 13 is the manipulator, 14 is the pre-processing room, 15 is the substrate bonding room (vacuum chamber), 16 is the post-processing room, 17 is the ultraviolet irradiation room, 18 is the second inspection room (panel inspection room) , 19 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap