Rack for enclosure product assembly

A technology for products and cabinets, applied in the field of racks for assembling cabinet products, can solve problems such as difficulty in arranging workstations, missing objects, and difficulty in removing and repairing, achieving the effects of easy production and control, high assembly efficiency, and saving production line space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

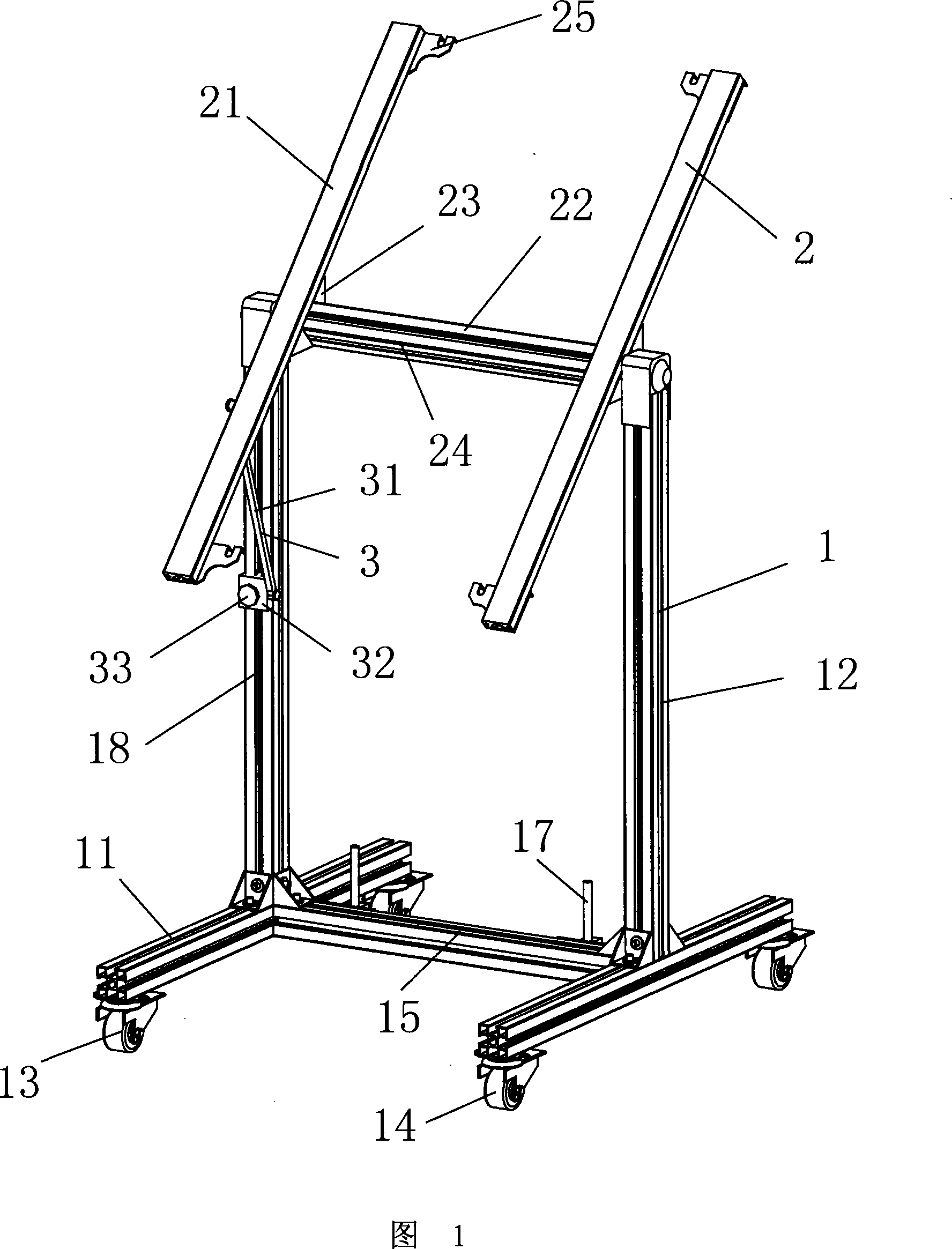

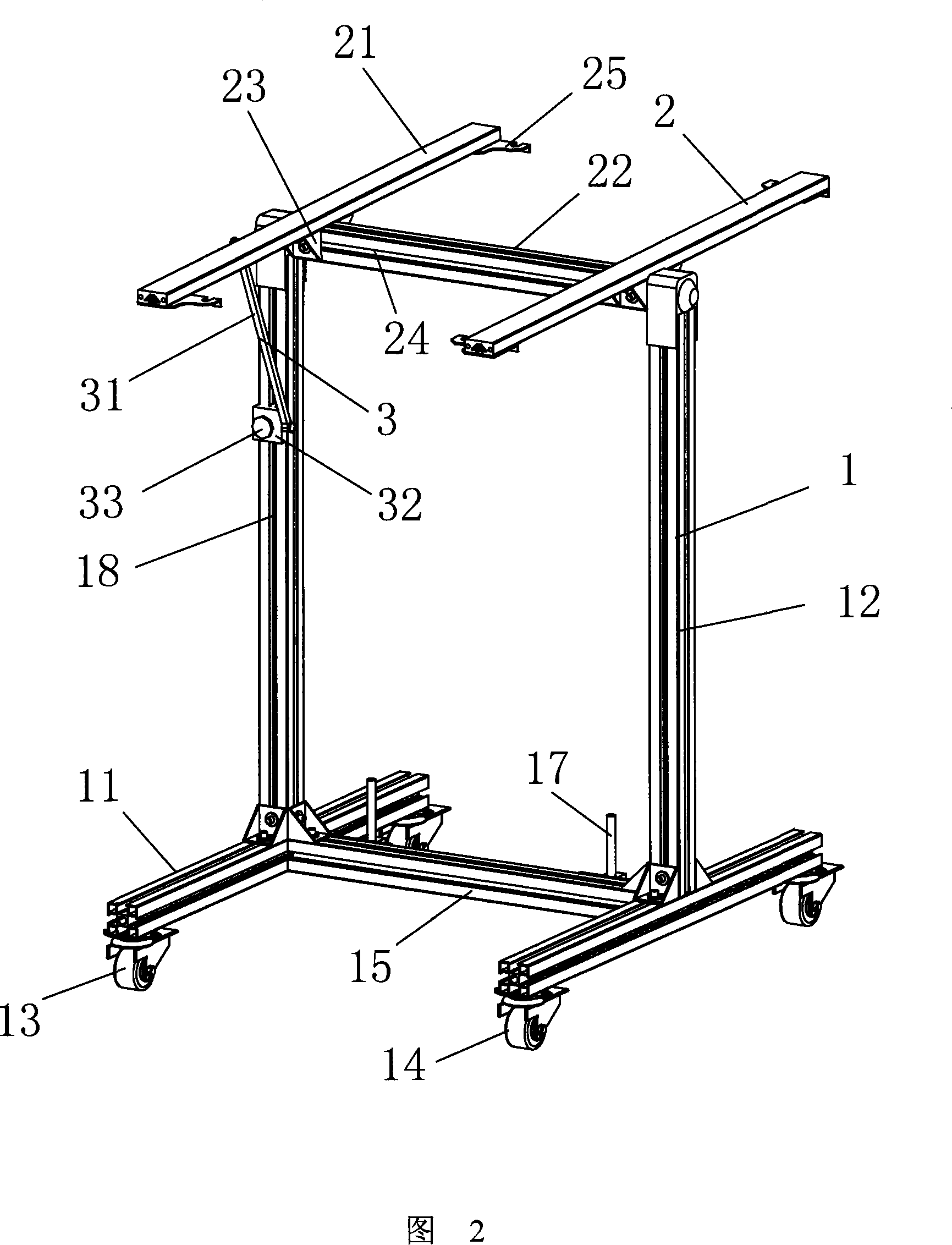

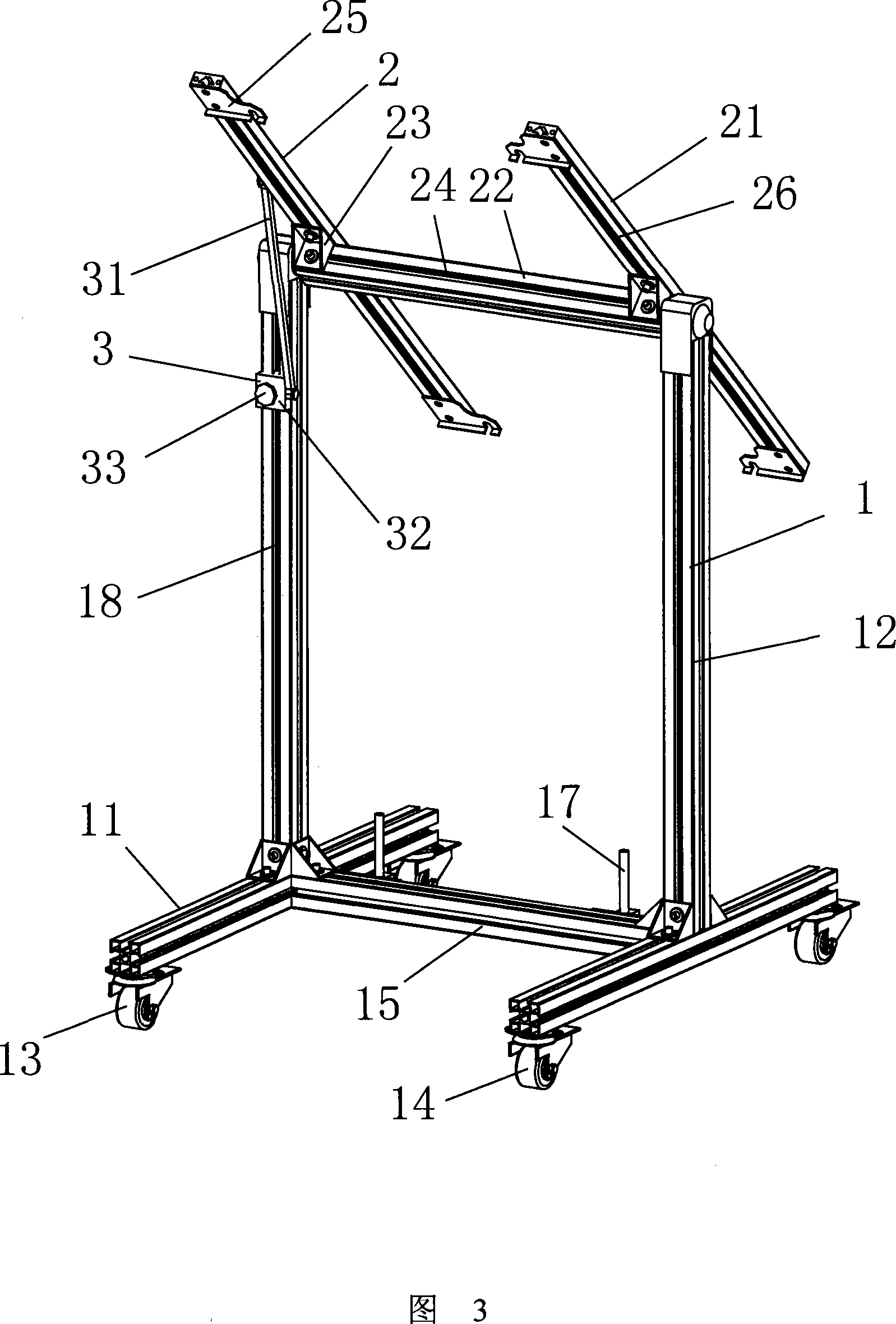

[0021] Embodiment: As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, a bracket for cabinet product assembly includes a support frame 1, the upper end of the support frame 1 is pin-connected with an upper frame 2, and the unit can be installed on the upper frame 2 , A positioning mechanism 3 is installed between the upper frame 2 and the support frame 1 .

[0022] The positioning mechanism 3 includes a connecting rod 31, one end of the connecting rod 31 is pinned to the upper frame 2 left and right, the other end of the connecting rod 31 is pinned to the left and right with a slider 32, and the slider 32 is pierced with a set bolt 33 , the support frame 1 is provided with an up and down guide groove 18 , the ends of the set bolts 33 are slidably embedded in the guide groove 18 and the slider 32 can be locked on the support frame 1 . Therefore, the pitch angle of the upper frame 2 can be freely adjusted and the upper frame 2 can be locked, which can realize the assembly of componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com