Method for manufacturing watercraft commutation tube

A manufacturing method and catheter technology, which is applied in shipbuilding, manufacturing tools, ship parts, etc., can solve the problems of long manufacturing hours, high cost, and low precision, and achieve the effects of saving manufacturing time, improving production efficiency, and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The practical application of the method of the present invention will be specifically described below with the manufacture of a rectifying duct on a 50,000-ton ship.

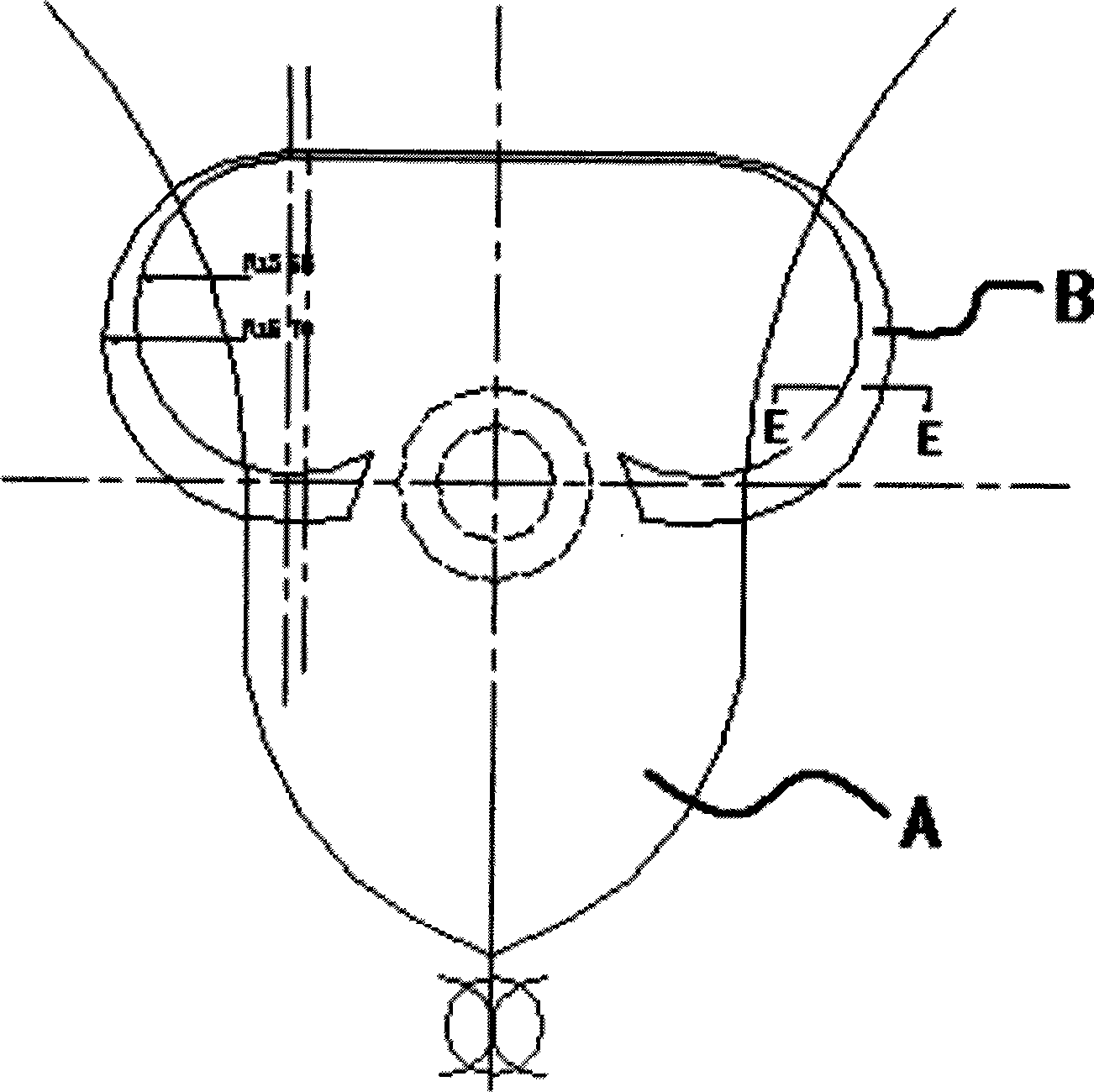

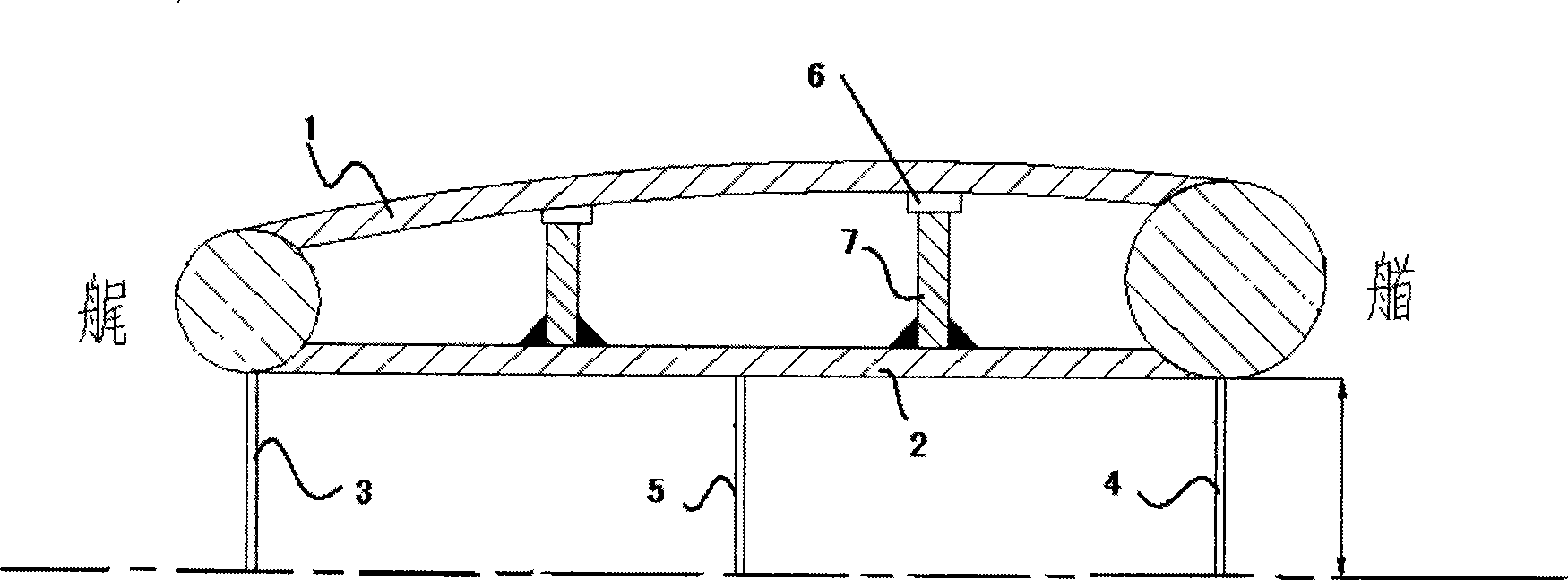

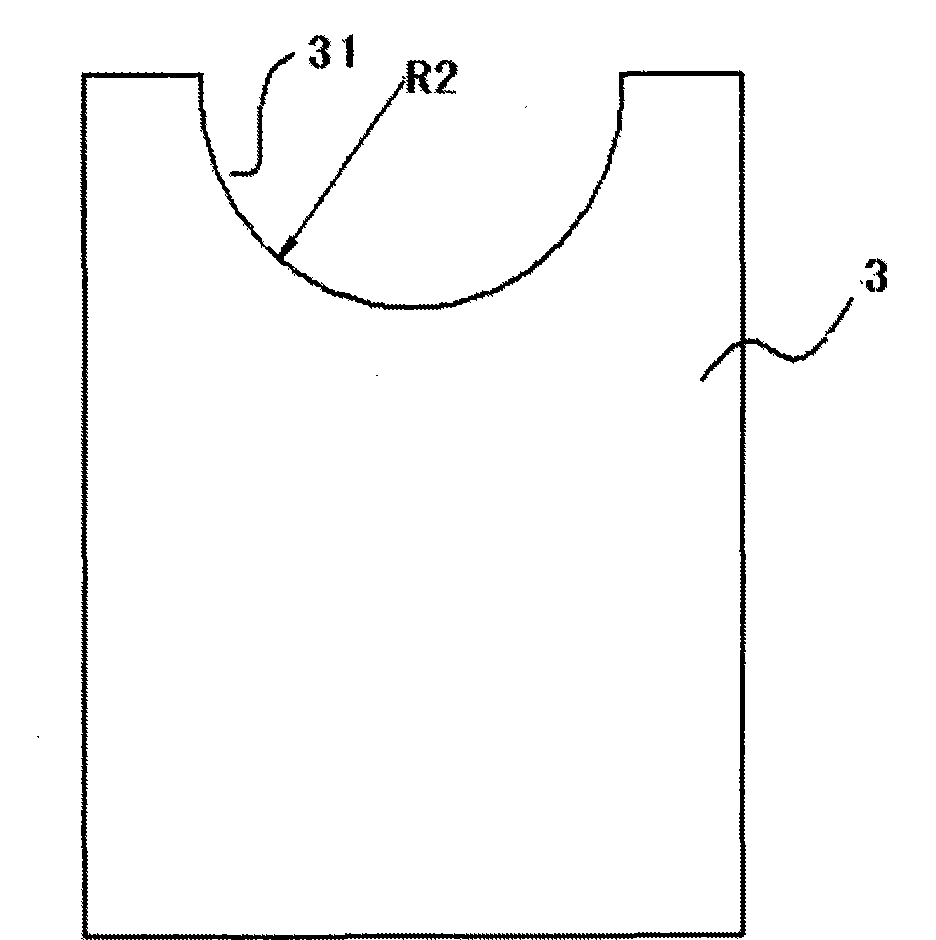

[0030] The rectifying duct includes an inner shell plate 1 and an outer shell plate 2, wherein the outer shell plate 2 is a semi-conical frustum shape, the radius of one end is R1=1570mm, and the radius of the other end is R2=1355mm. The inner shell plate 1 is formed by a plurality of blocks. The inner shell plate 1 and the outer shell plate 2 are fixed by a rib plate 7, one end of the rib plate 7 is welded to the scribed line position in the outer shell plate 2, and the other end is fixed with a plurality of rib plates 7, one end of the plurality of rib plates 7 After being fixed on the outer shell plate 2 , the end contacting with the inner shell plate 1 has the same line shape as the inner shell plate 1 . The inner shell constituent plates are welded and fixed at the upper ends of the plurality of rib ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com