Method for replacing disabled bolt weight anchor at speed improving runway switch crossing sleeper of railway

A replacement method and bolt technology, applied in the directions of roads, tracks, buildings, etc., can solve problems such as being unsuitable for maintenance of skylights, unable to take out bolt casings, etc., and achieve the effect of long cooling time of thermal energy, short operation time and high operation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with an embodiment.

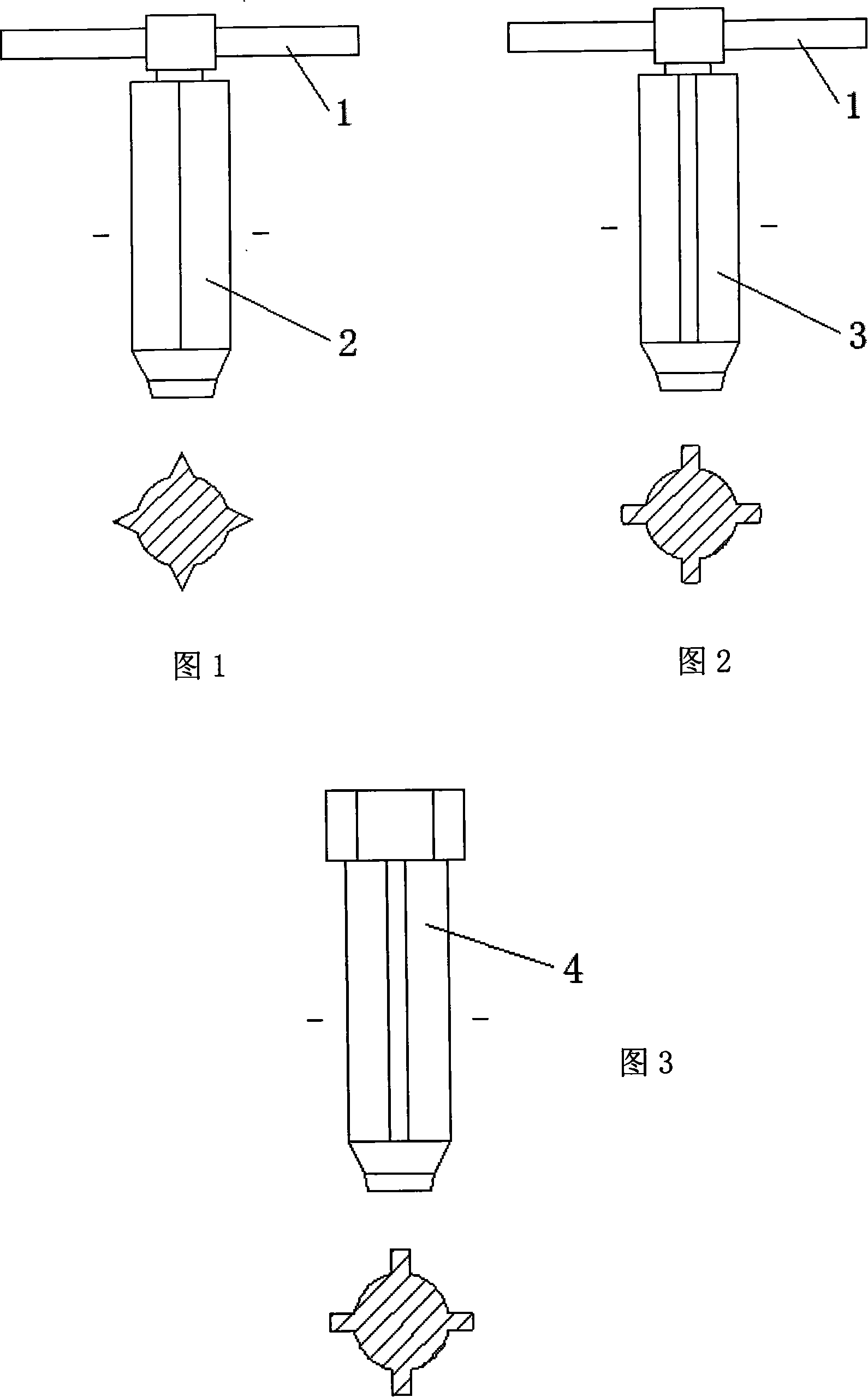

[0030] The tool that the present invention adopts is the supporting use of mold 1 and four-spline shaft, as shown in Figure 1 and Figure 2. The corners of No. 1 four-spline shaft 2 are triangular, and the purpose is to reduce the downstroke resistance of the four-spline shaft during fusing and pressing. The edges and corners of the No. 2 four-spline shaft 3 are square.

[0031] The embodiment of the replacement method of the present invention is divided into nine steps:

[0032] In the first step, burn the front end 1 to 8 cm of No. 1 four-spline shaft 2 to 240° C. with oxyacetylene.

[0033] In the second step, align the red-hot No. 1 four-spline shaft 2 with the bolt bushing for melting and pressing. At the same time, a pressure of 70kgf is applied above the mold 1, so that the No. 1 four-spline shaft 2 is quickly melted and pressed to the bottom end of the bolt sleeve. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com