Device for testing and analyzing warehouse separated type denitrated catalyzer

A denitration catalyst, testing and analysis technology, applied in the field of SCR denitration catalyst sampling, analysis and detection devices in power plants, can solve the problems of poor comparability of test results, long interval time, long time consumption, etc., and achieves the effect of saving analysis and testing time and increasing comparability

Active Publication Date: 2011-01-05

CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, only when the boiler is shut down, the denitrification catalyst is taken out from the catalyst layer in the boiler and returned to the catalyst manufacturer or sent to the laboratory for analysis to observe the mechanical strength, service life and poisoning of the catalyst. According to the activity test, pressure drop loss, mechanical Strength, poisoning resistance, service life and flue gas adaptability to make comprehensive evaluation intervals are long, and replacement is inconvenient. Therefore, it is impossible to make timely judgments on the poisoning situation and causes of denitrification catalysts, especially for the suitability and suitability of various denitrification catalysts. For the test and comparison of good conditions, each catalyst must be used in the denitrification of the flue gas of the same boiler under the same environmental conditions, and the trial period is the same, and then each catalyst is taken out and returned to the catalyst manufacturer or sent to the experiment. It takes a lot of time to conduct comprehensive analysis and comparison in the laboratory, and the environment of each catalyst will change due to changes in various parameters of the flue gas discharged from the boiler, resulting in poor comparability of test results.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

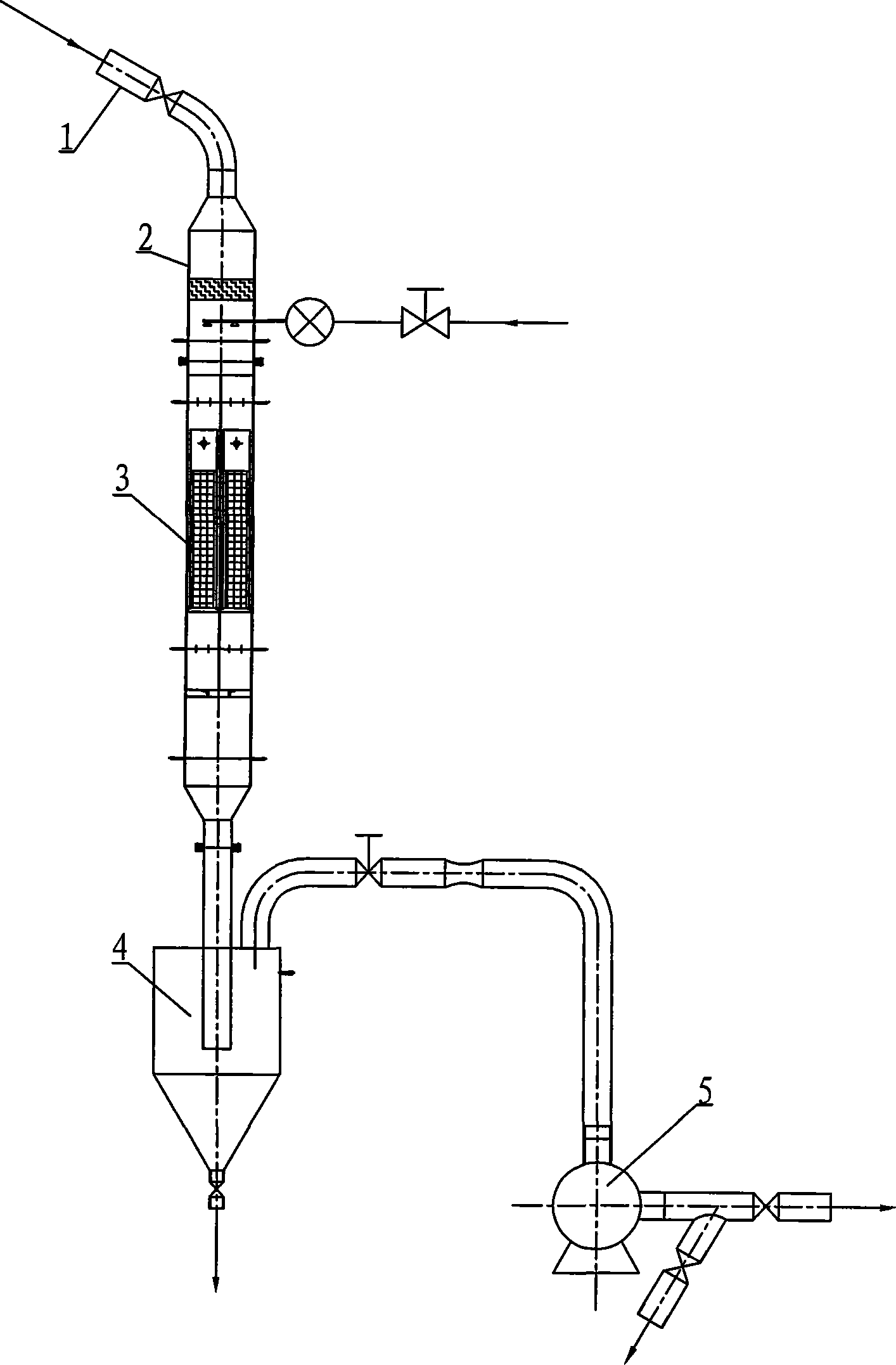

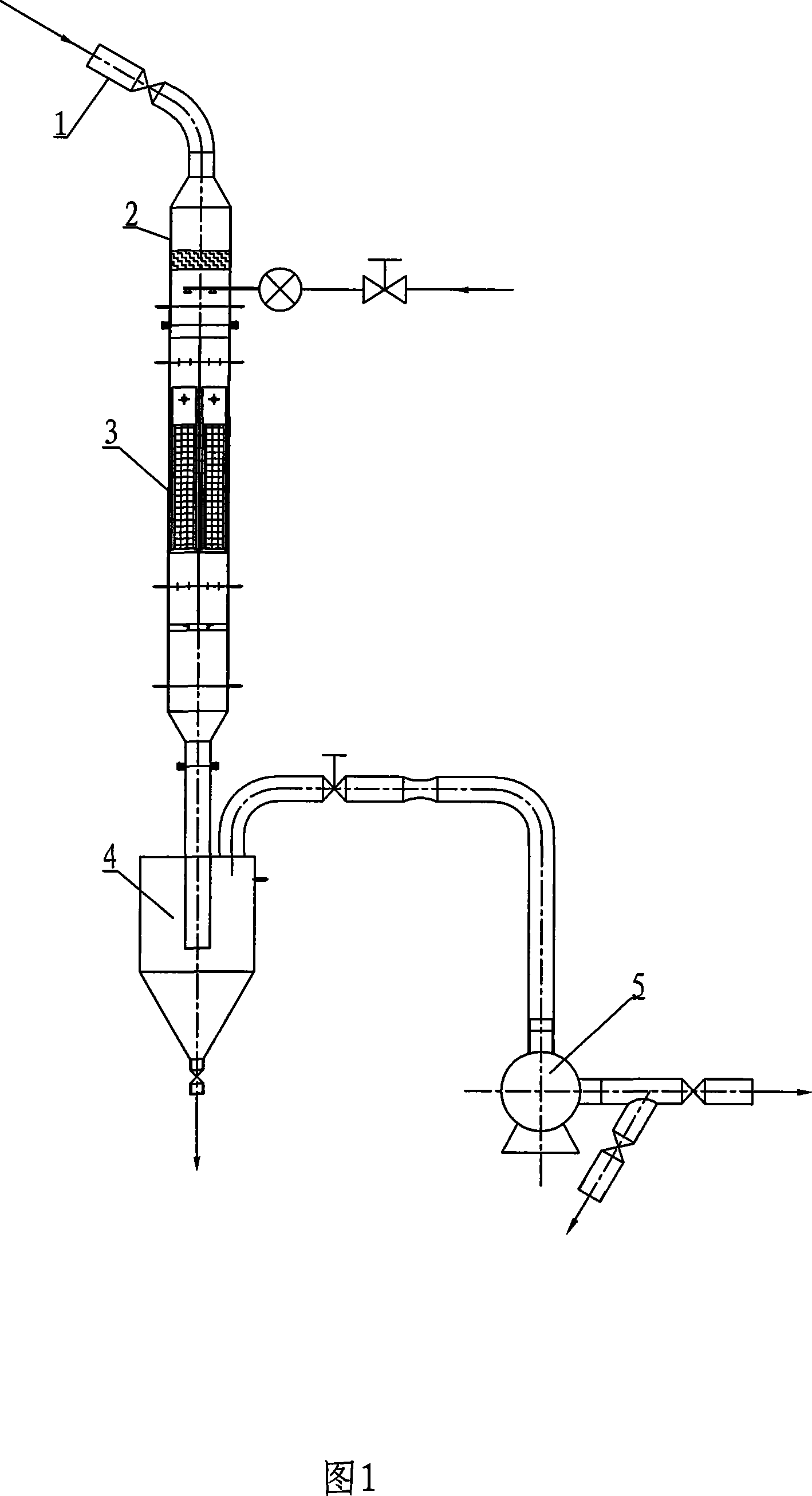

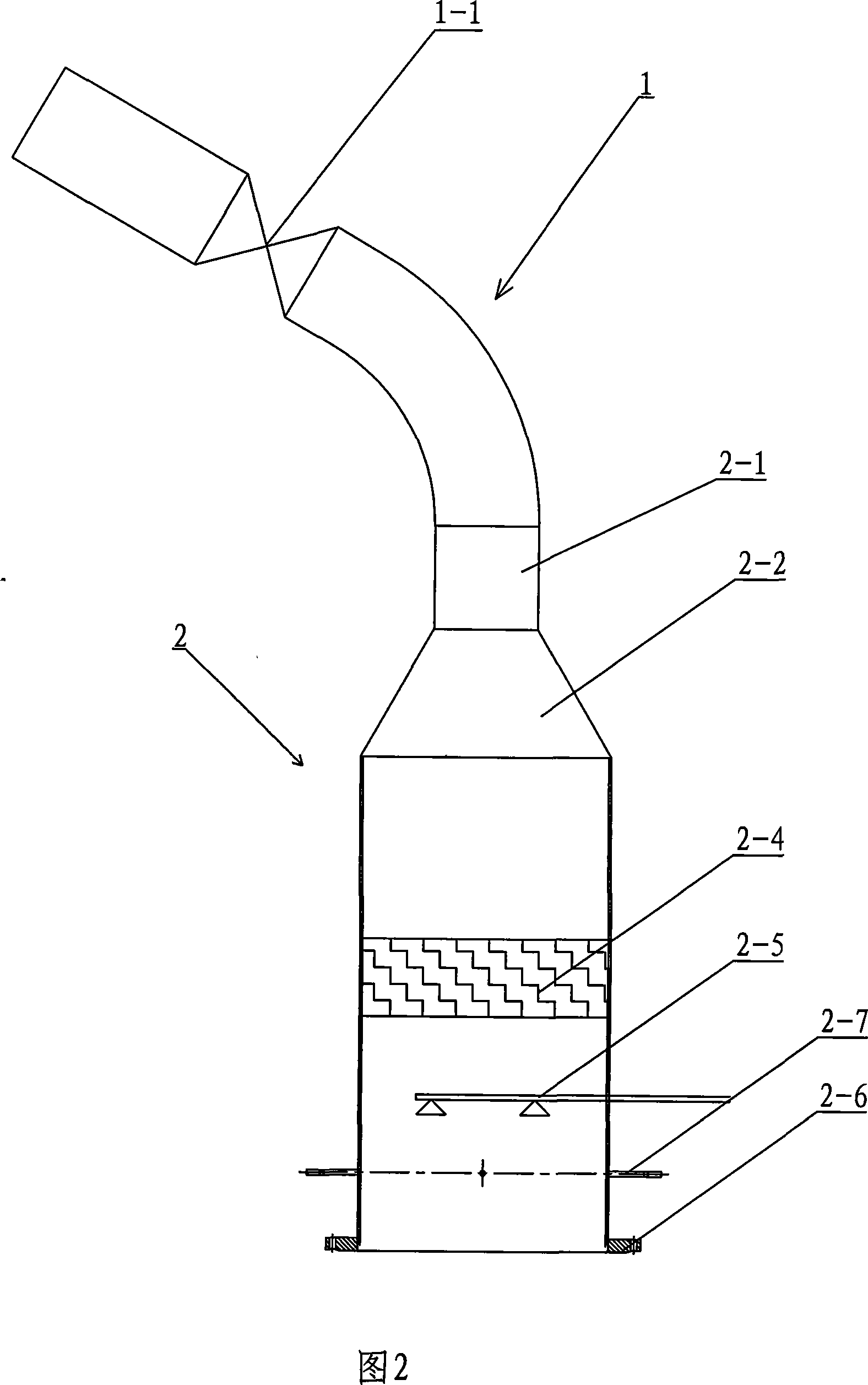

The invention discloses a split testing and analyzing device for a denitration catalyst. A split testing reactor (3) communicates a smoke mixing assembly (2) and a smoke cleaning assembly (4); the inner cavity of the split testing reactor (3) are divided into four cavities (3-2) by partition boards (3-1); in the middle of each cavity (3-2), a catalyst basket (3-3) is placed; the catalyst basket (3-3) comprises a main pipe and a sieve mesh; on the catalyst basket (3-3), a hanging hole is provided; between the upper and the lower opening of the cavity (3-2) and the catalyst basket, a sampling port is provided for measuring temperature and pressure for each cavity (3-2). The invention can concurrently carry out performance comparison and test on denitration catalysts of different specifications and types under the same smoke conditions, saves greatly the analysis and test time, and increases the comparability.

Description

Separate bin type denitration catalyst testing and analysis device technical field The invention relates to a sampling, analysis and detection device for SCR denitration catalysts in power plants, in particular to a compartmentalized denitration catalyst testing and analysis device that can compare the performance of catalysts of different types and specifications under the same flue gas conditions. Background technique The denitration catalyst is the core of SCR denitration in power plants, and its performance has a decisive influence on the performance of denitration engineering. The unreasonable selection of catalyst will not only cause the denitration rate and other indicators of denitrification to fail to reach the guaranteed value, but also cause the blockage of the catalyst and the increase of pressure drop, resulting in the failure of boiler operation. In addition, if the catalyst is not selected properly, it may also cause the poisoning of the catalyst. , wear and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N31/10G01N1/22G01N33/00

Inventor 李锋杜云贵罗小渝刘清才彭期耀尹正明廖帆隋建才杨剑王方群洪燕许川

Owner CPI YUANDA ENVIRONMENTAL PROTECTION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com