Gas drying device

A technology of gas drying and drying machine, which is applied in the field of drying gas devices and drying compressed gas devices, and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

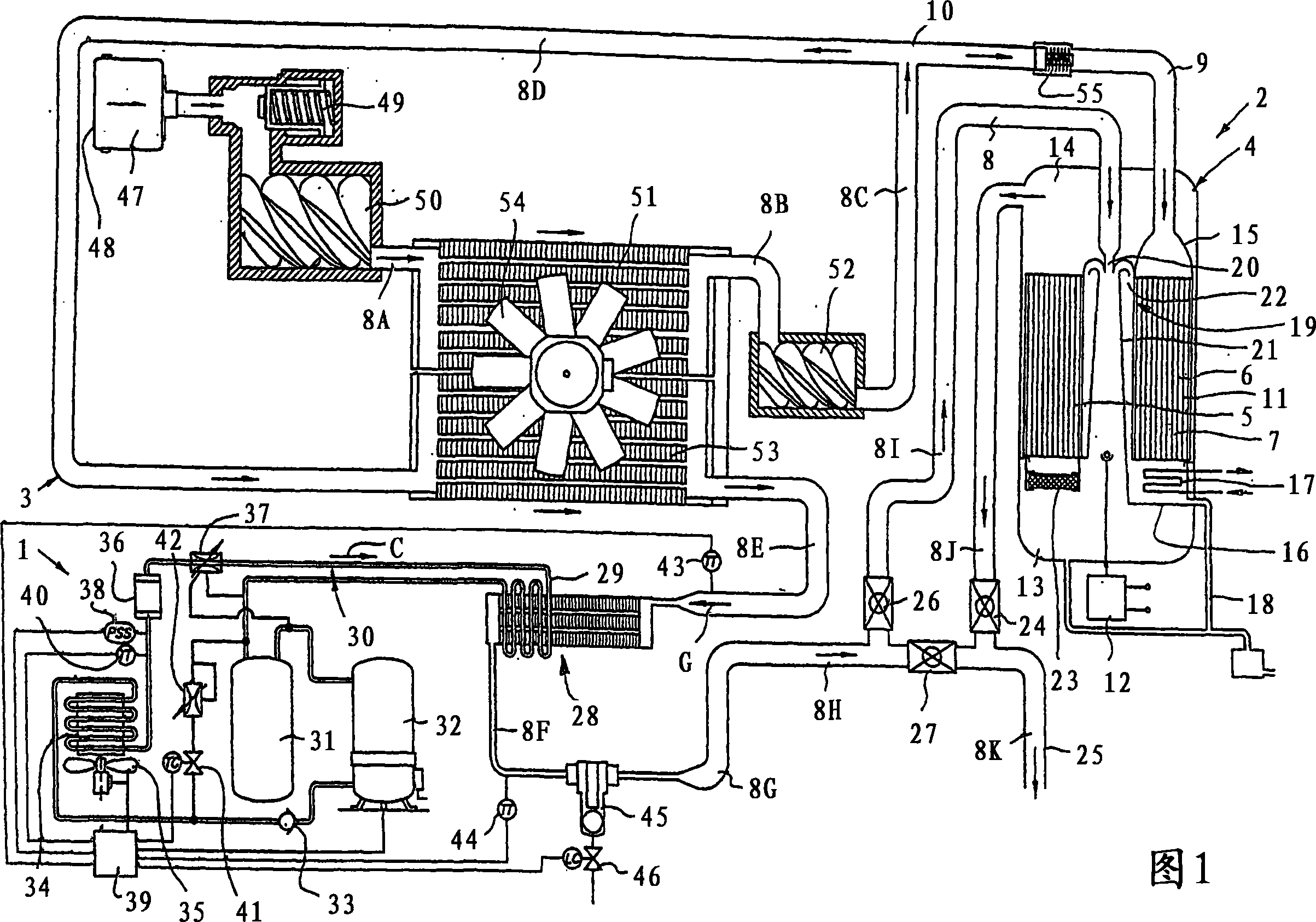

[0012] As shown in Fig. 1, the gas drying device mainly includes a cooling dryer 1, a dehumidifying dryer 2, and a compressor part 3 in this embodiment.

[0013] The dehumidifying dryer 2 uses a pressure box 4 type. The pressure box 4 has a drying zone 5 and a regeneration zone 6 with adsorption and / or absorption media 7 which are alternately guided through the drying zone 5 and the regeneration zone 6.

[0014] In addition, the device also includes a primary circuit 8 including pipes having parts 8A, 8B, 8C, 8D, 8E, 8F, 8G, 8H, 8I, 8J, and 8K, the above-mentioned cooling dryer 1, the dehumidifying dryer 2 and the above-mentioned The compressor part 3 is connected to the primary circuit 8. The primary circuit 8 makes it possible to compress the gas to be dried first, then at least partially dry it in the cooling dryer 1 and then lead it through the dehumidifying dryer 2 The drying zone 5 can be further dried.

[0015] The device also includes a secondary circuit 9, which serves as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com