Drilling stress meter for one-hole multiple measuring points

A borehole stress gauge and multi-point measurement technology, which is used in earth-moving drilling, wellbore/well components, etc. problem, to achieve the effect of convenient one-hole multi-point installation, low power consumption, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

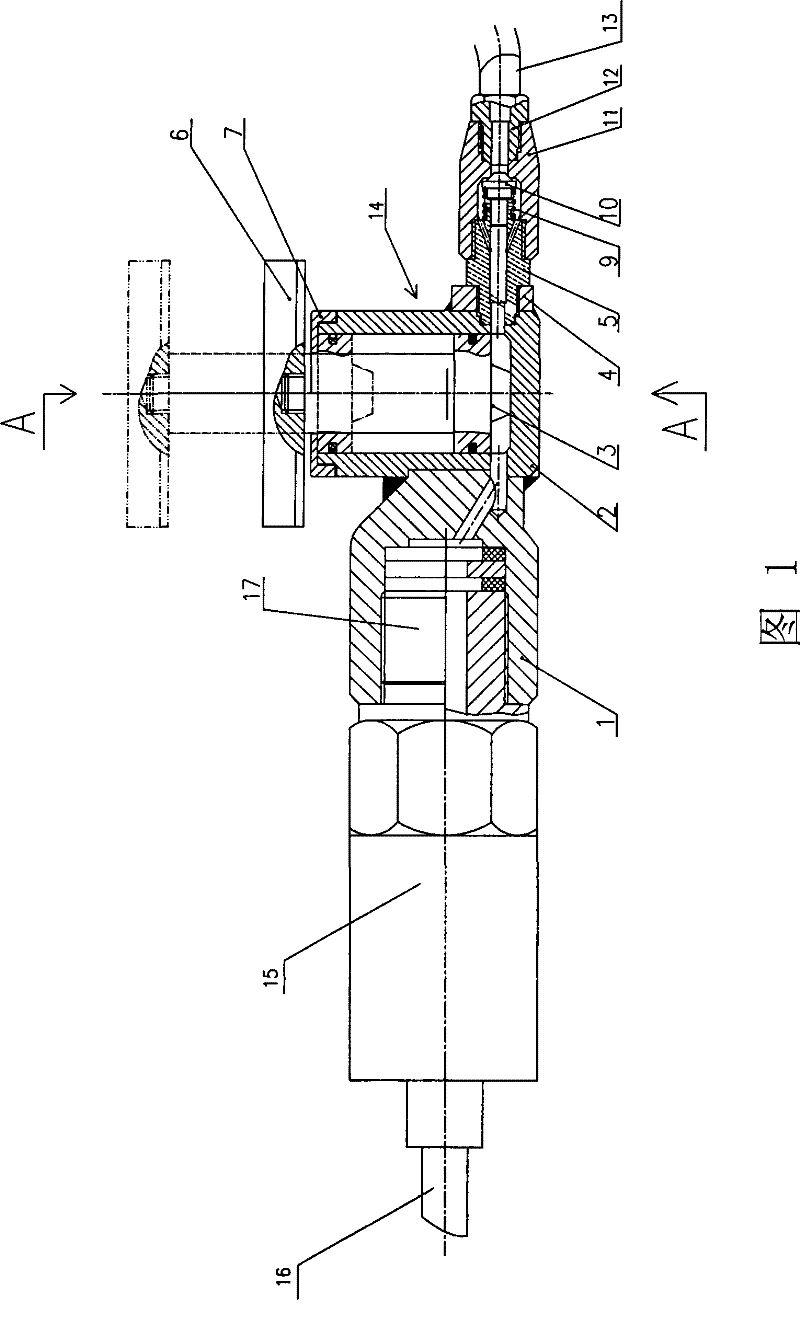

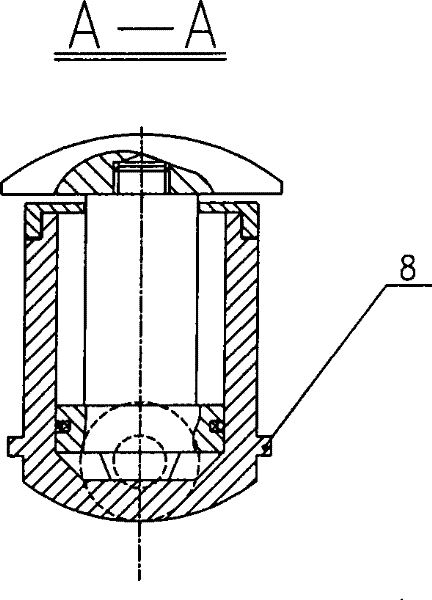

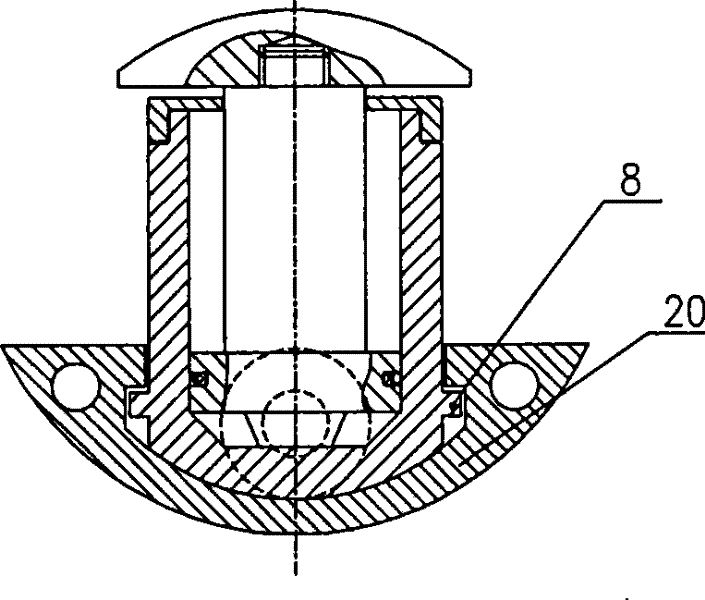

[0022] see Figure 1 to Figure 6 Shown: a kind of borehole strain gauge of multi-point measurement in one hole, it comprises hydraulic oil cylinder 14, pressure sensor 15, and pressure sensor selects piezoresistive or capacitive pressure sensor, and described hydraulic oil cylinder 14 is vertically arranged, in One side of the lower end of the hydraulic cylinder 14 is connected and connected to the pressure signal sensitive end 17 of one end of the pressure sensor 15, and the other end of the pressure sensor 15 is connected with a signal output pin 16; A one-way valve 11 for internal oil delivery, which is connected to an oil delivery pipe 13 with a diameter of Φ6.

[0023] A top plate 6 is connected to the top of the plunger 3 of the hydraulic cylinder. The top plate 6 is long and rectangular, and the top is arc-shaped. It is arranged longitudinally along the borehole 25 to ensure full contact with the top wall of the borehole; The guide sleeve 7 is connected; the one-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com