Mechanical tensioning device for dowm pressing

A tensioning device, mechanical technology, used in mechanical equipment, transmissions, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

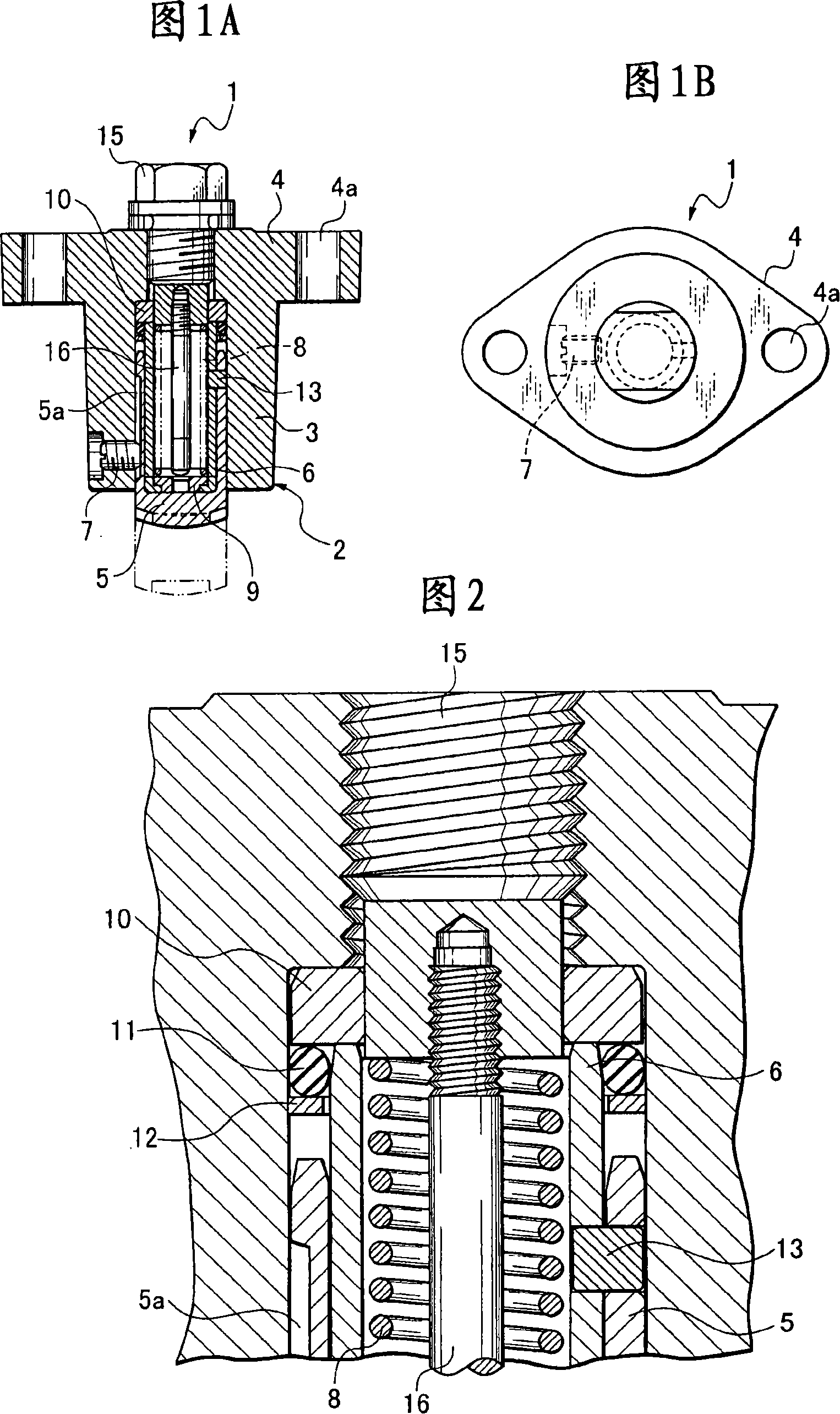

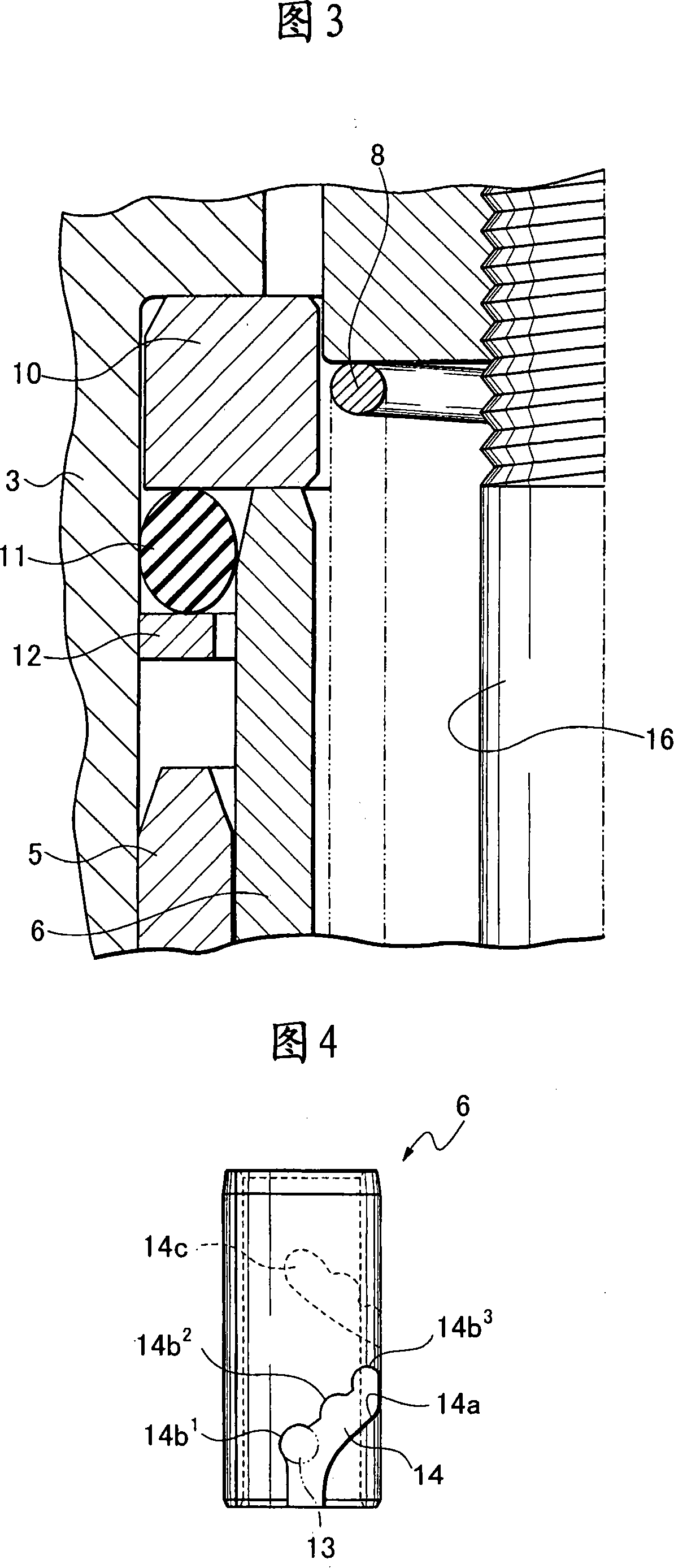

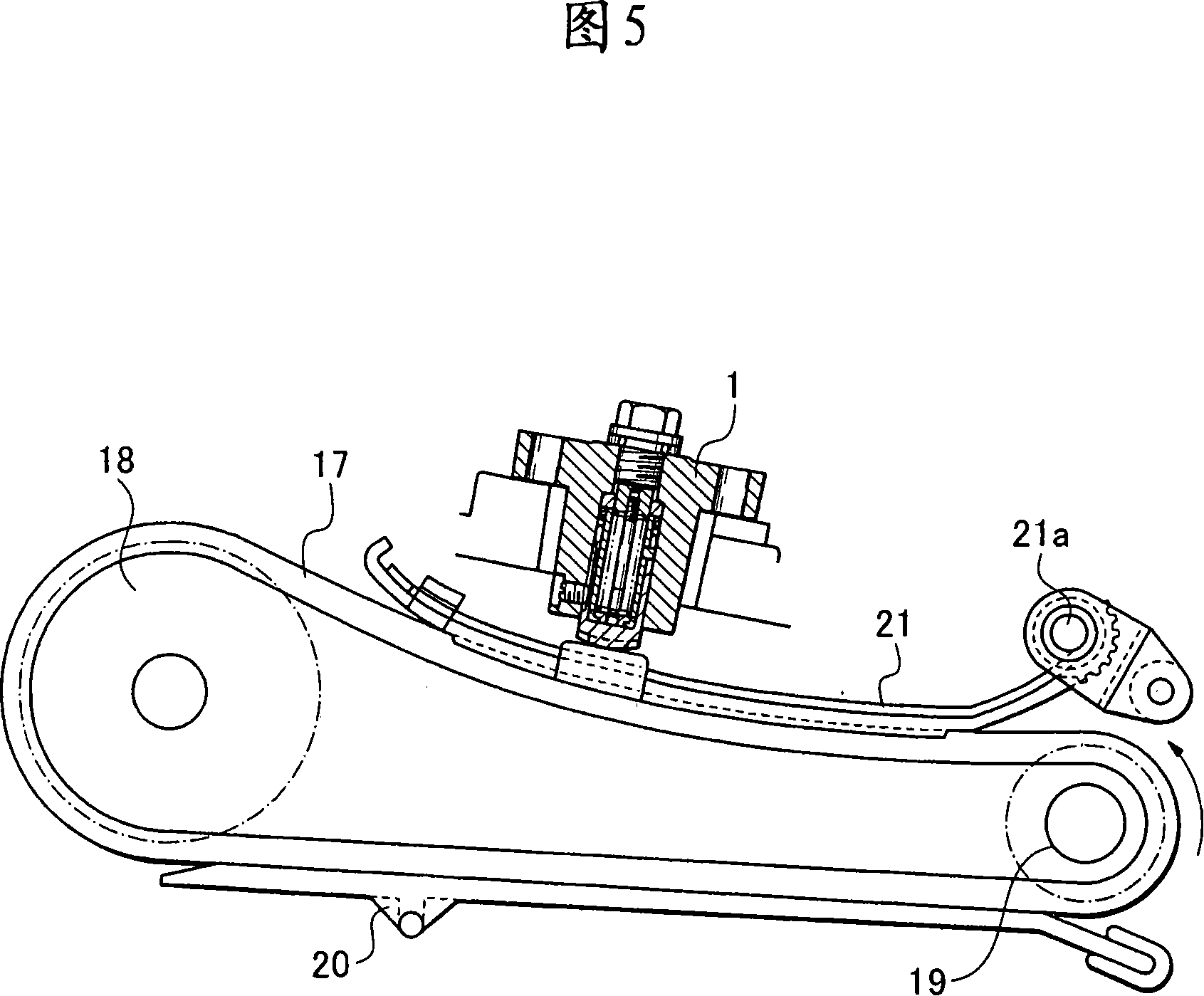

[0020] 1A and 1B show a mechanical tensioner for pressing down according to an embodiment of the present invention, which has a die-cast cylindrical main body 2 made of a cylindrical cylinder 3 and a boss for mounting on an engine block. An edge-shaped mounting part 4 is formed. A cylindrical plunger 5 having a head is slidably accommodated in the cylinder 3 , and a cylindrical pawl drive cylinder 6 is engaged in the plunger 5 . The main body 2 is attached to the engine block through bolt holes 4 a formed in the attachment portion 4 .

[0021] A notch 5a is formed on a part of the outer surface of the cylindrical portion of the plunger 5, and a detent pin 7 is screwed into a threaded hole penetrating through the side wall of the cylinder 3, and is rotatably restricted by the detent pin 7. Therefore, the plunger 5 can slide without turning and protrudes from the cylinder 3 . In addition, a columnar claw pin 13 is fitted and fixed in a hole penetrating through a part of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com