Portable universal large diameter measuring gage used for greatness diameter measurement and measurement method thereof

A diameter measurement, portable technology, applied in the direction of mechanical diameter measurement, can solve the problems of decreased measurement accuracy, difficult operation, increased length error of measurement unit, etc., to reduce diameter measurement error, ensure measurement accuracy, and reduce bending deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

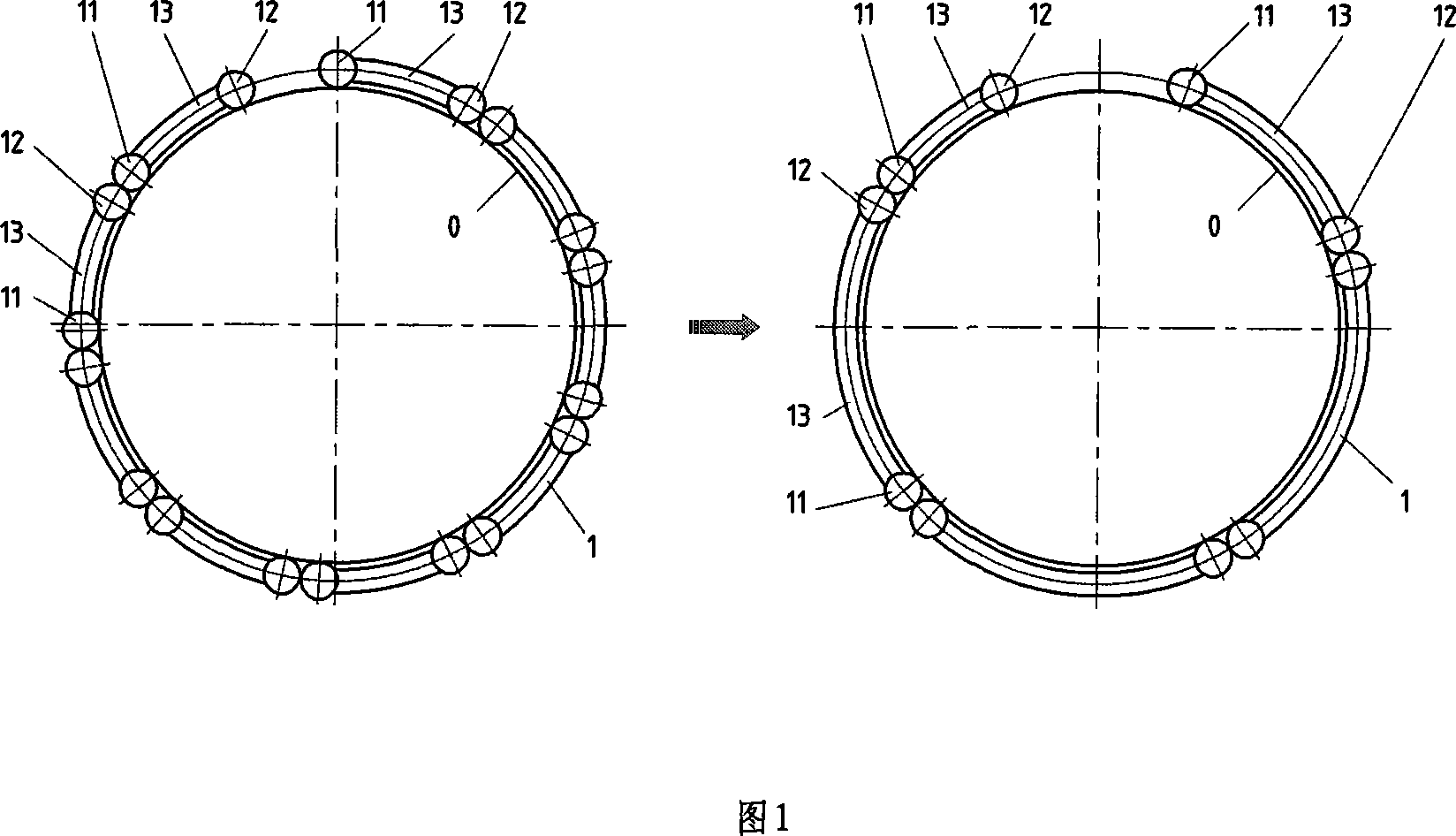

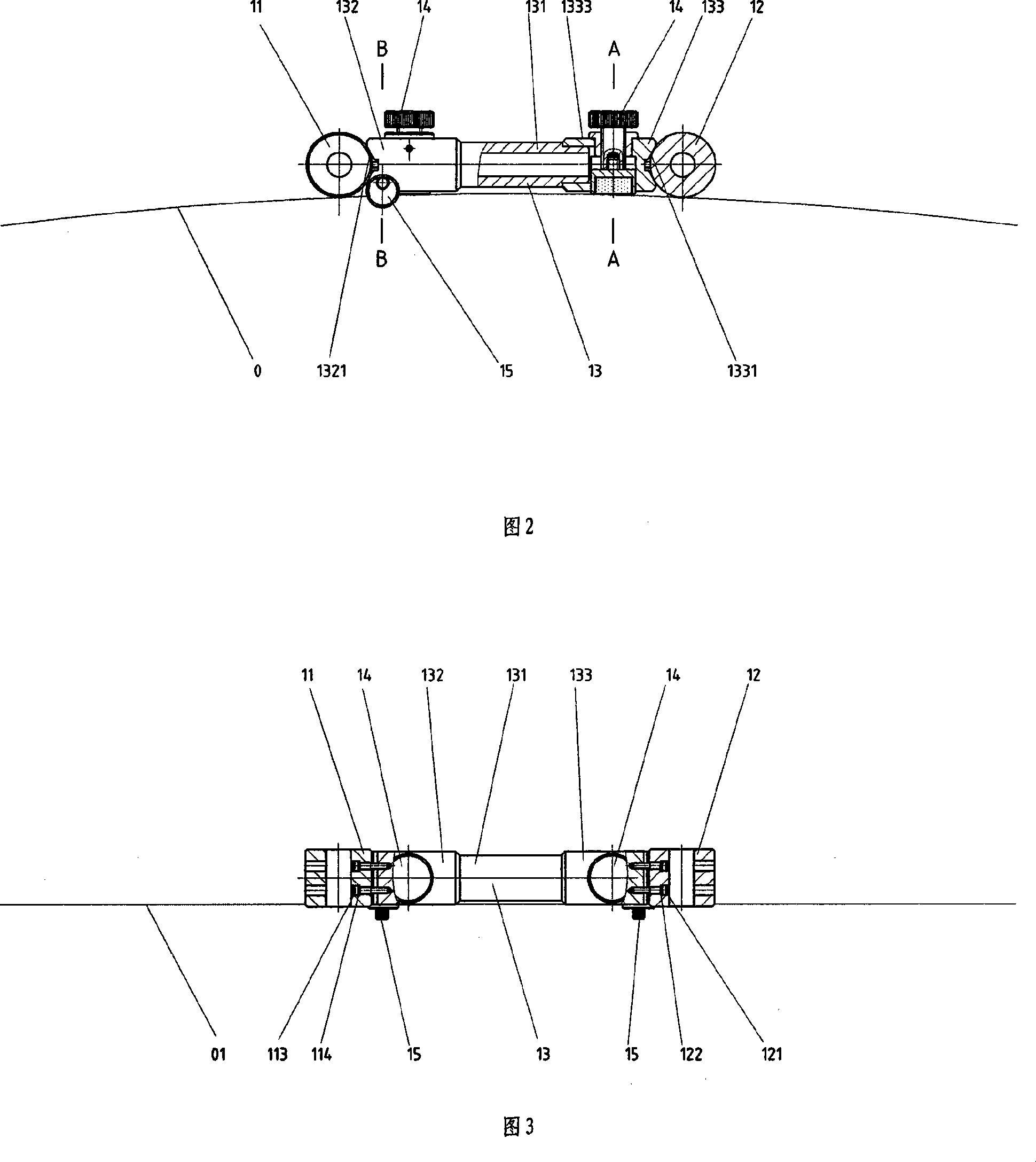

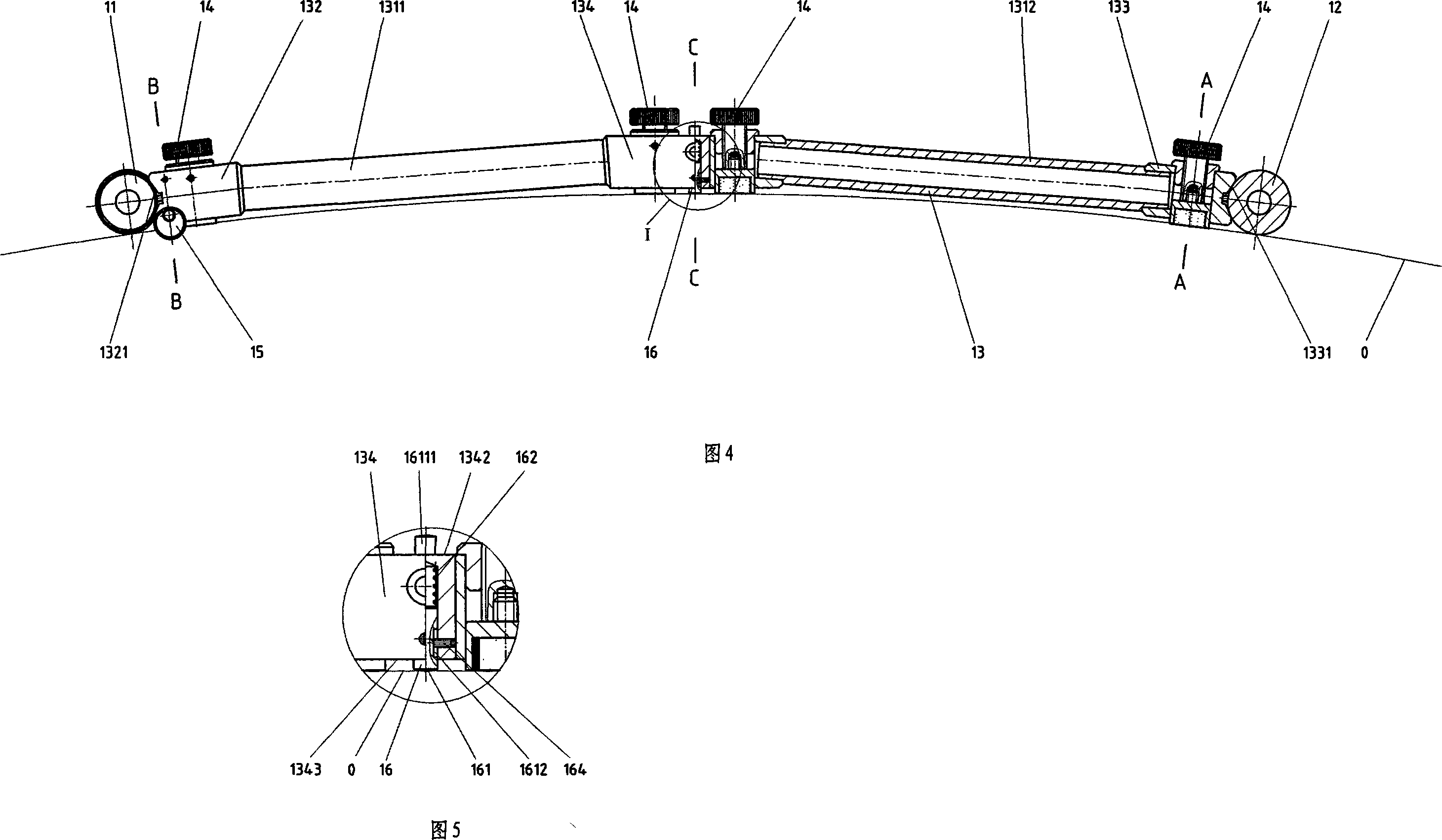

[0056] As shown in Fig. 2 to Fig. 18, the portable universal large-diameter measuring gauge for large-diameter measurement according to the embodiment of the present invention is composed of a series of mutually independent measuring units 1 and a kind of internal diameter micrometer 2 with a V-shaped measuring anvil. Each measuring unit 1 consists of a body 13, a front positioning element 11, a rear positioning element 12, several identical fixing mechanisms 14 comprising permanent magnets 1411, two identical auxiliary positioning mechanisms 15, and for longer measurement The unit 1 is provided with an auxiliary supporting mechanism 16 that includes an auxiliary supporting element 161 that can be moved and locked, wherein the front positioning element 11 and the rear positioning element 12 are located at both ends of the body 13, and the fixing mechanism 14, The auxiliary positioning mechanism 15 and the auxiliary supporting mechanism 16 are located on the body 13 . The inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com