Coat rack discharging gear in the clothes-making workstation

A workstation and hanger technology, applied in the direction of sewing tools, conveyor objects, transportation and packaging, etc., can solve the problems of loud noise, deviation of hangers, unable to enter the main track of the assembly line normally, etc., to achieve low noise and work. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

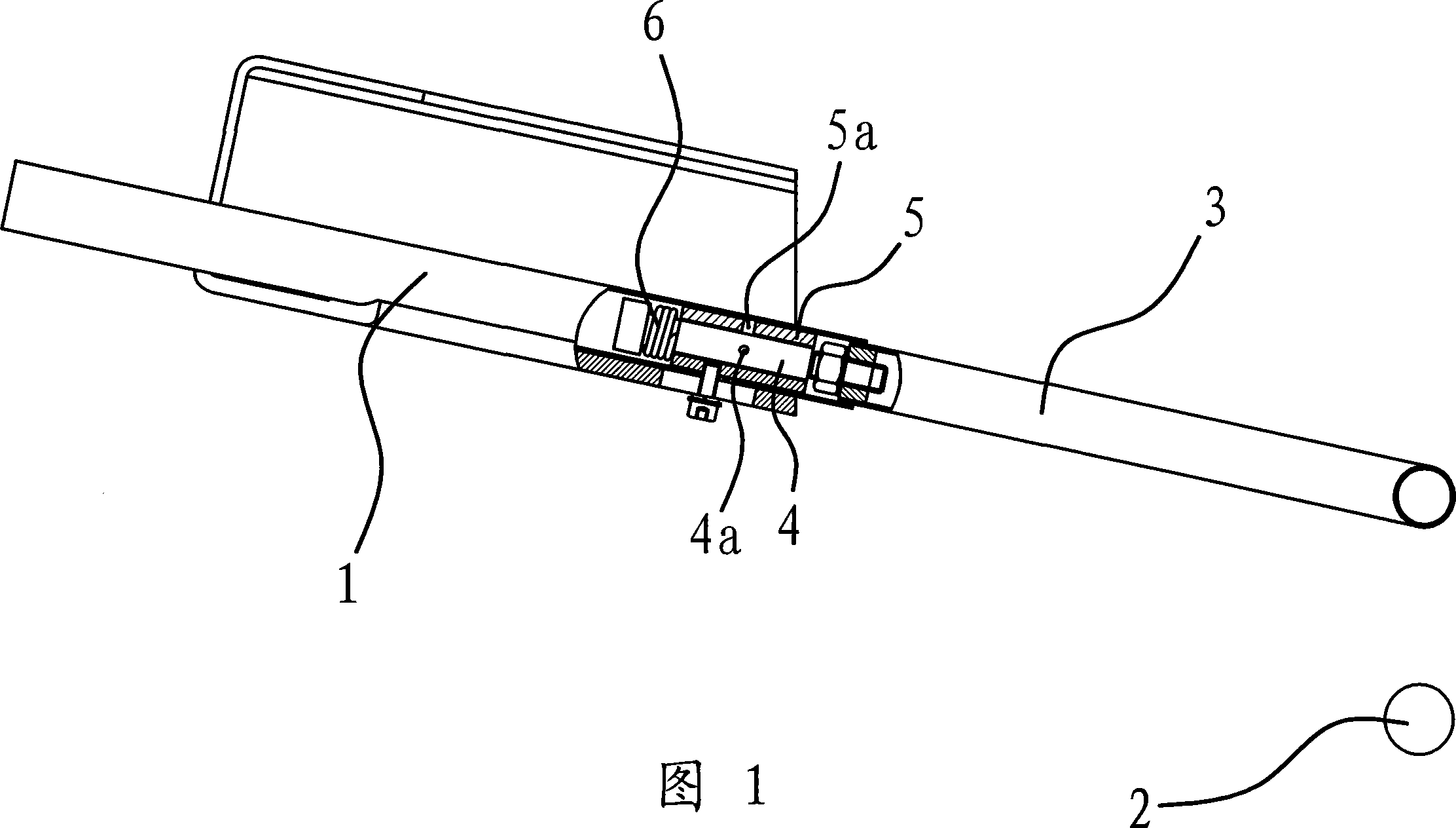

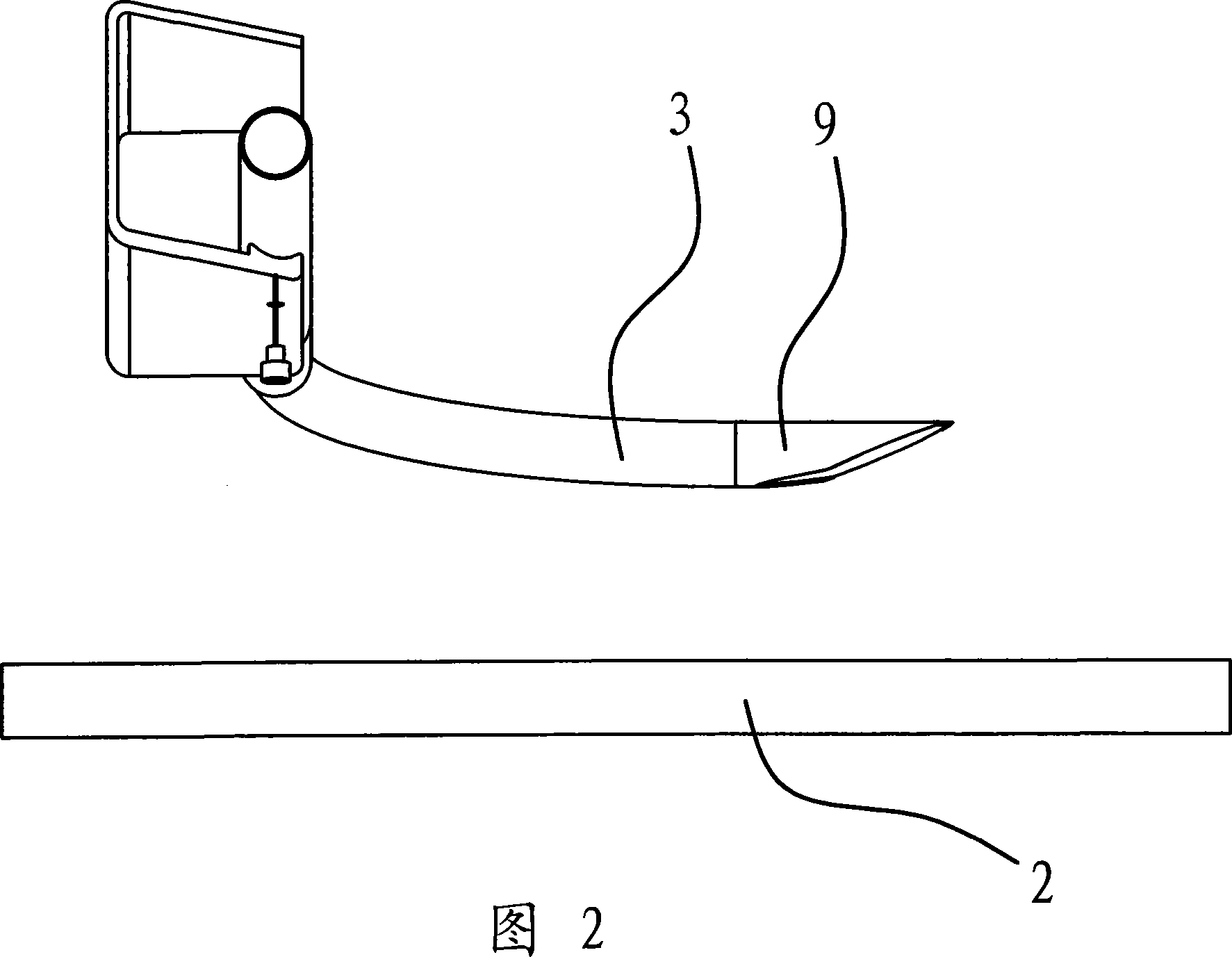

[0030] As shown in Fig. 1 and Fig. 2, the outbound mechanism of the clothes hanger in the garment-making workstation is arranged between the front end of the guide rail 1 at the end of the lifting arm and the main rail 2 at the exit of the garment-making workstation. The main rail 2 is used for the clothes hangers 10 with clothes to pass through in turn, and the end guide rail 1 of the lifting arm at the exit is located at the side of the main rail 2 .

[0031] The outbound mechanism of the clothes hanger in this garment-making workstation comprises an outbound guide rail 3 axially fixed on the end guide rail 1 of the elevating arm. The outbound guide rail 3 is L-shaped and its corner is a circular arc transition. In this embodiment, the outbound guide rail 3 is made of a hollow tube.

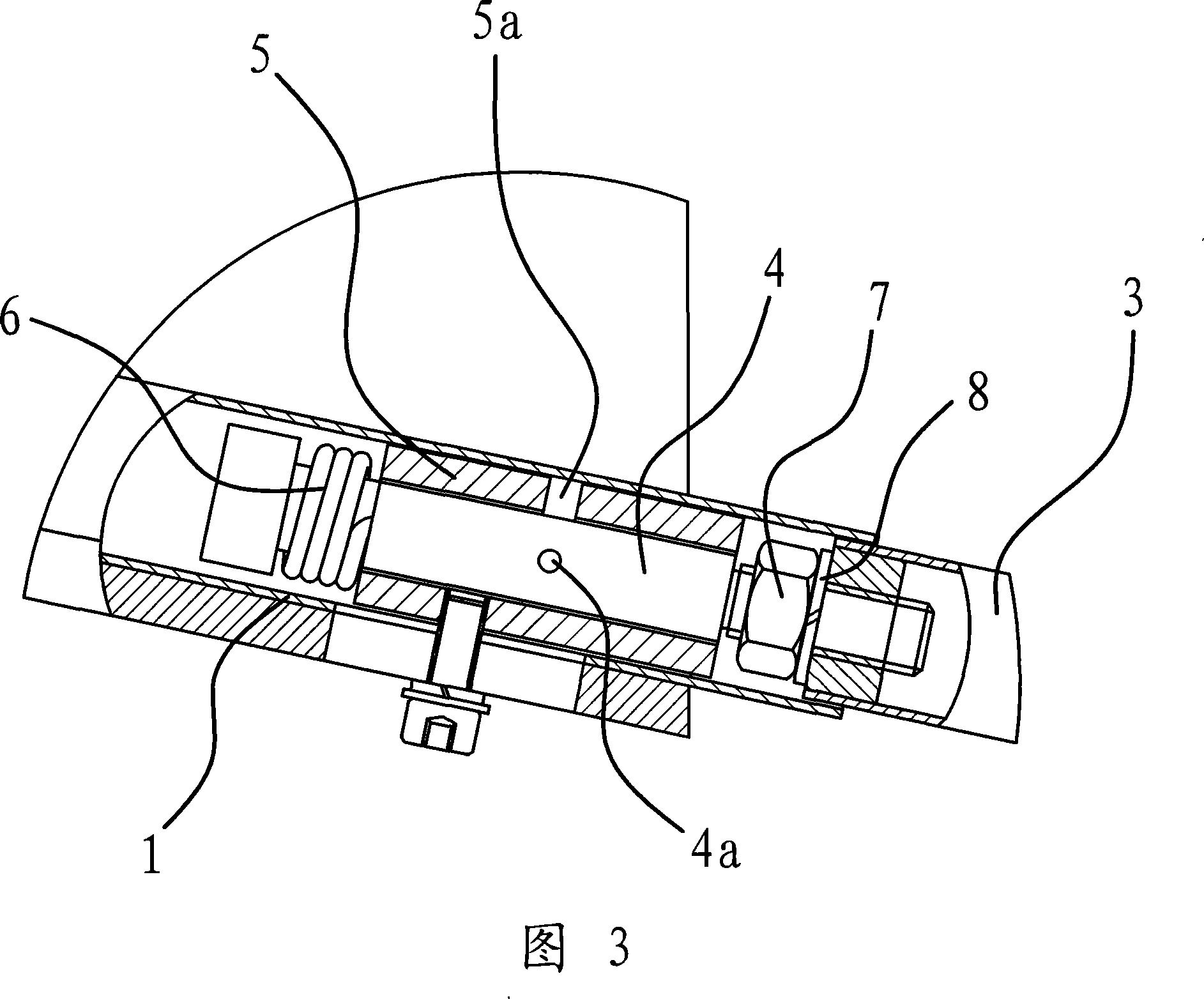

[0032] As shown in Figure 3, a reset rotation device is provided between the outbound guide rail 3 and the end guide rail 1 of the lifting arm. The reset rotation device includes a rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com