Sawblades in couple

A technology of paired saw blades and saw blades, which is applied in the direction of sawing machine devices, metal sawing equipment, and knives of sawing machine devices, and can solve problems such as inconvenient repair and maintenance, reduced work efficiency, and increased work loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

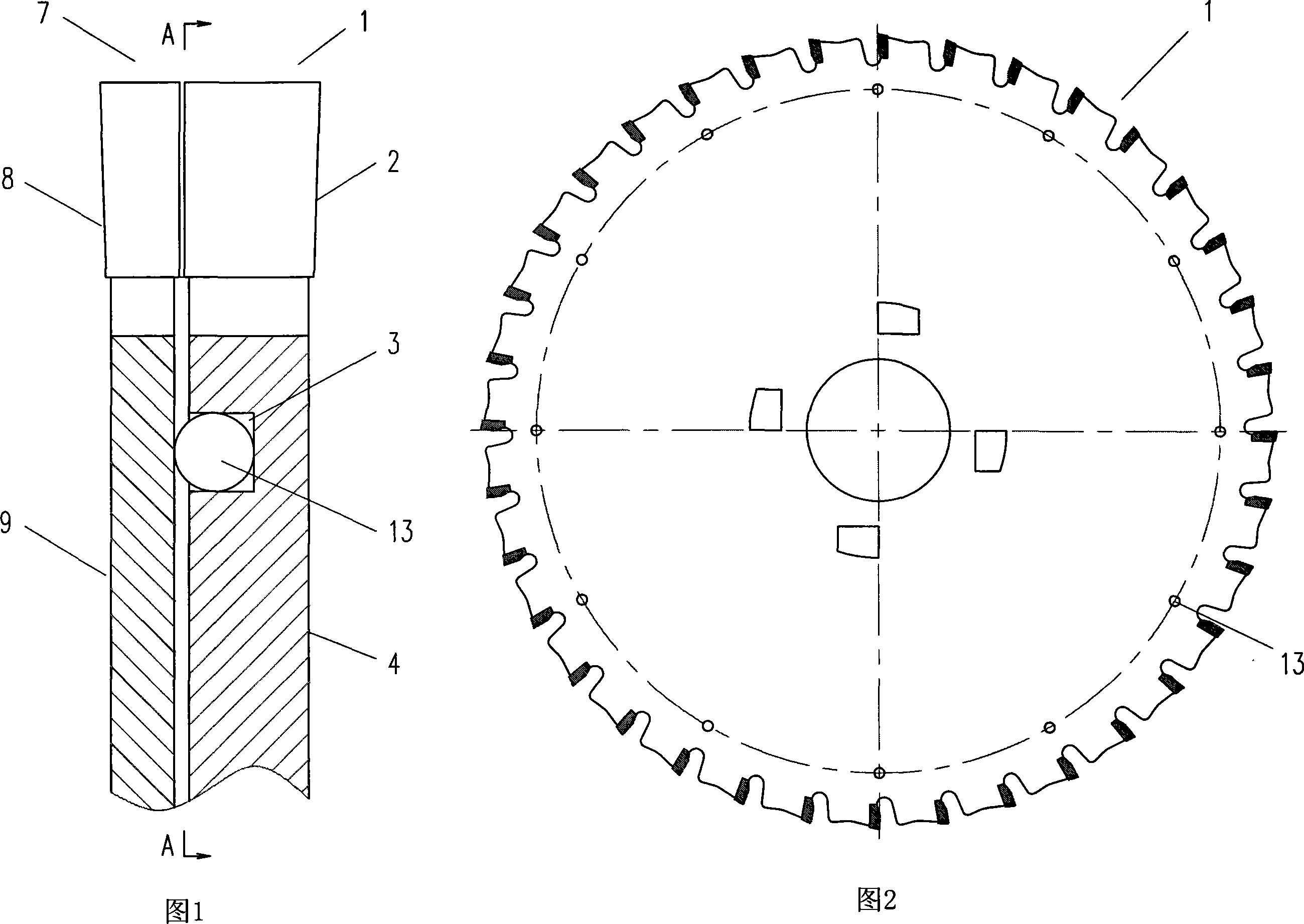

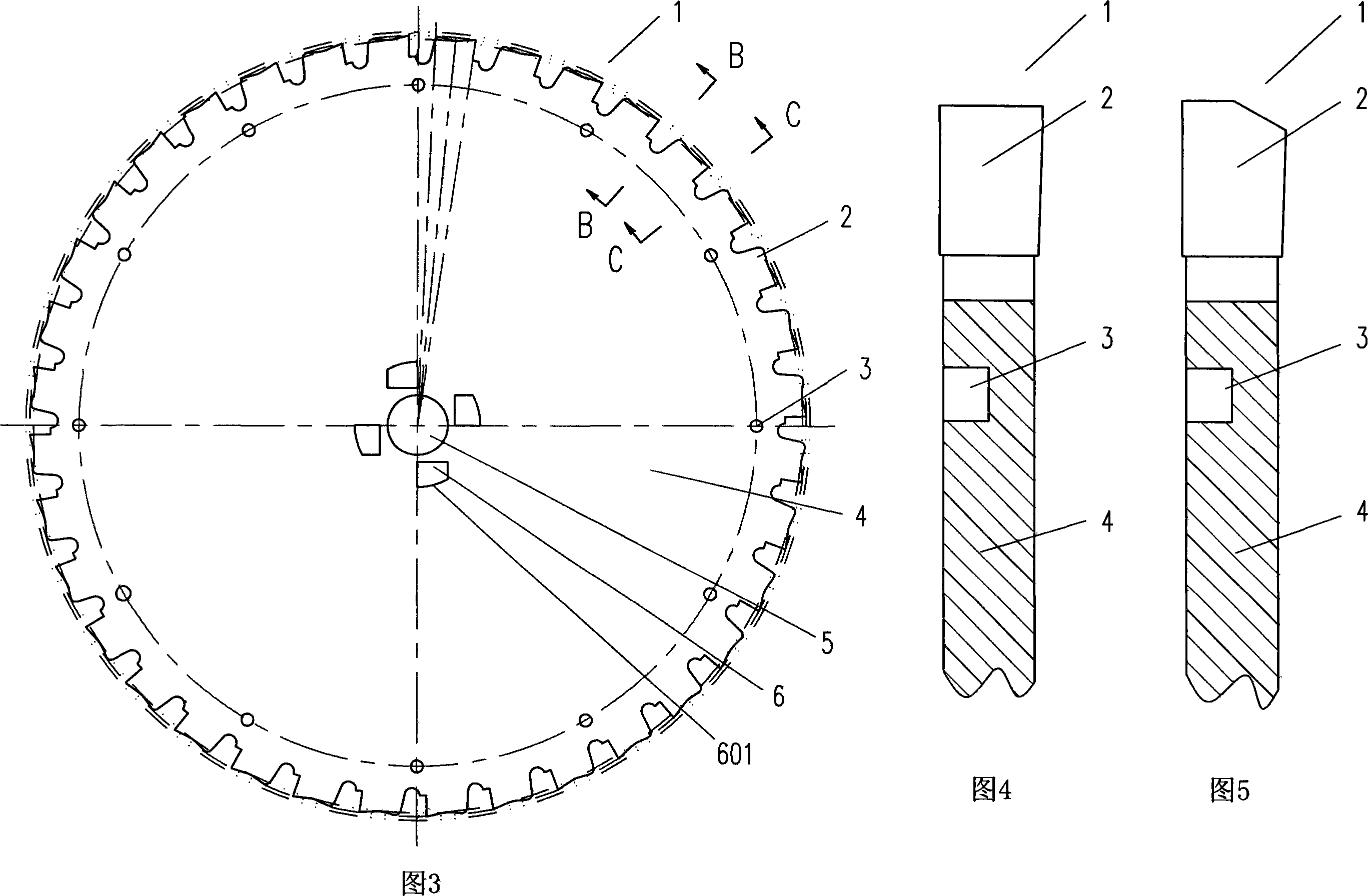

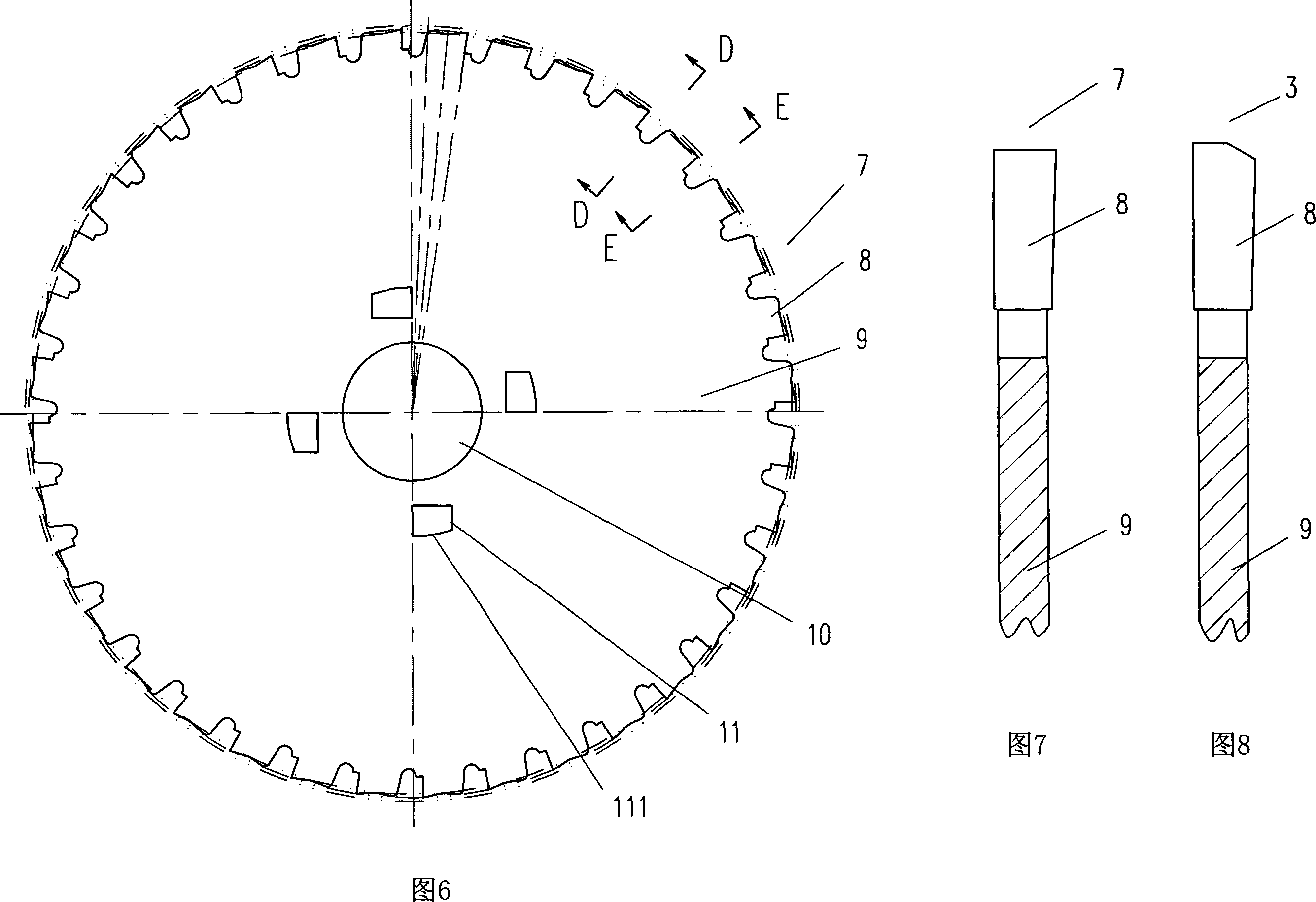

[0039] Referring to FIGS. 1-5 , a double saw blade includes an outer saw blade 1 rotating around an axis, an inner saw blade 7 counter-rotating around the same axis, and a set of balls 13 . The outer saw blade 1 includes a saw blade body 4 and a cutting element 2 arranged on the periphery of the saw blade body. A group of cylindrical grooves 3 are arranged on the saw blade body 4 near the cutting element 2, and the cylindrical annular groove 3 faces inwardly. Saw blade 7; the set of balls 13 are embedded in the corresponding cylindrical groove 3 one by one, and the two sides are respectively in contact with the saw blade body 9 of the inner saw blade 7 and the groove bottom of the groove 3, so that the outer saw blade 1 A certain gap is maintained between the saw blade body 4 of the inner saw blade 7 and the saw blade body 9 of the inner saw blade 7, and is in a rolling state during the relative movement of the two saw blades. There is a center hole 5 in the center of the saw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com