Leveler intelligent leveling system and its method

A leveling machine and leveling technology, which is applied in the direction of soil mover/excavator, use feedback control, construction, etc., can solve problems such as limitations and easy misoperation, and achieve smoothness of operation, fast and efficient automatic adjustment The effect of flat work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

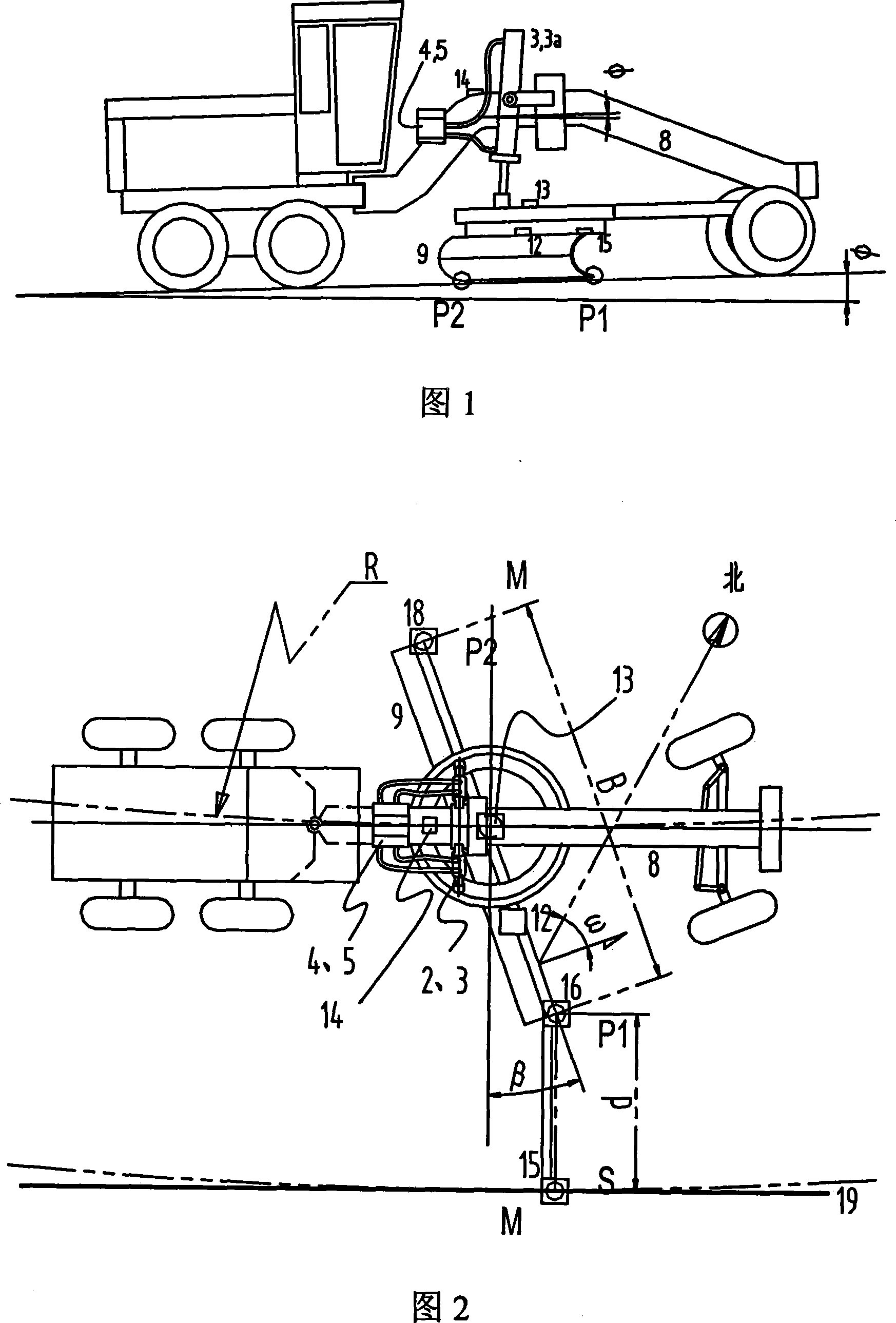

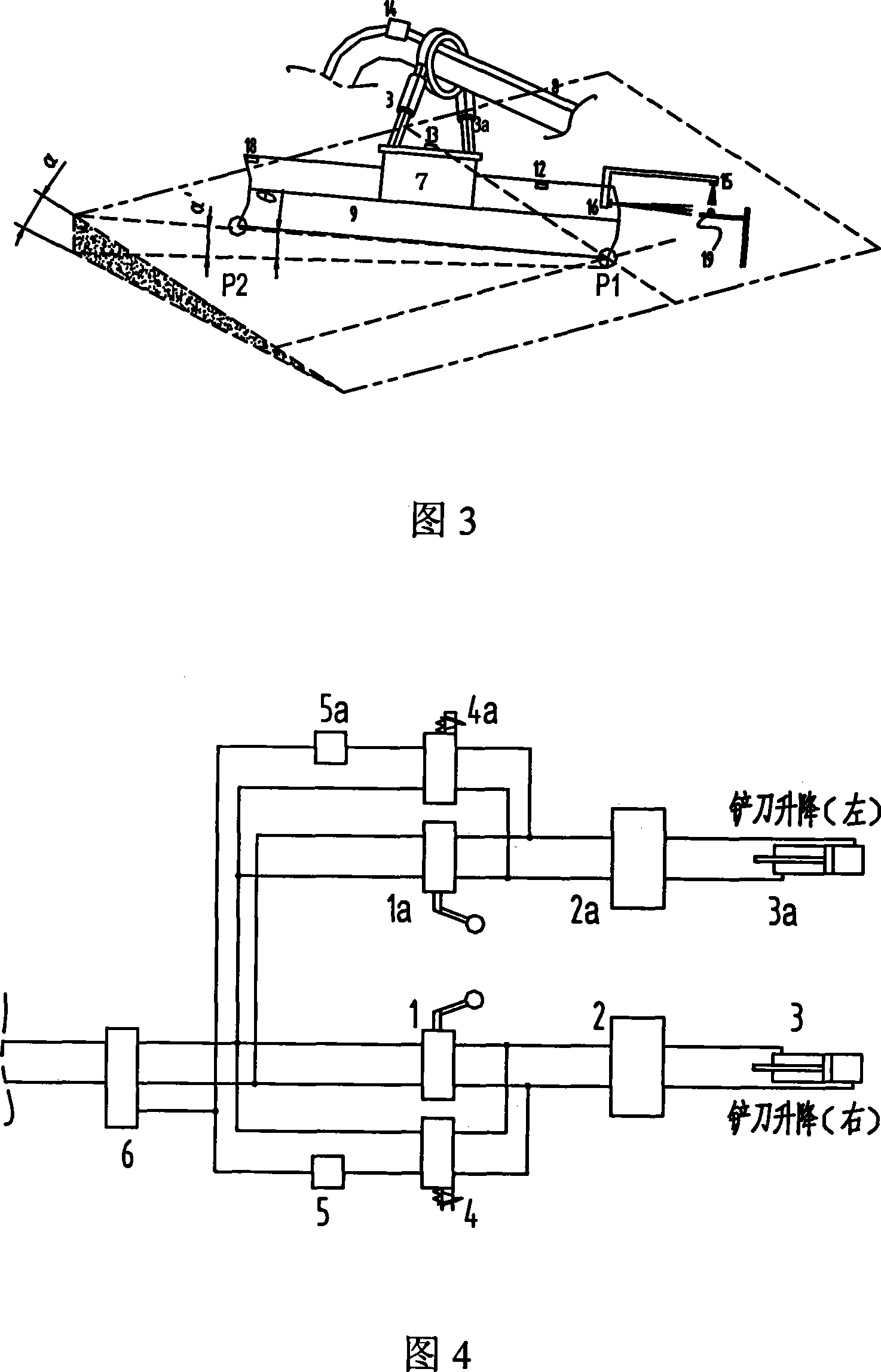

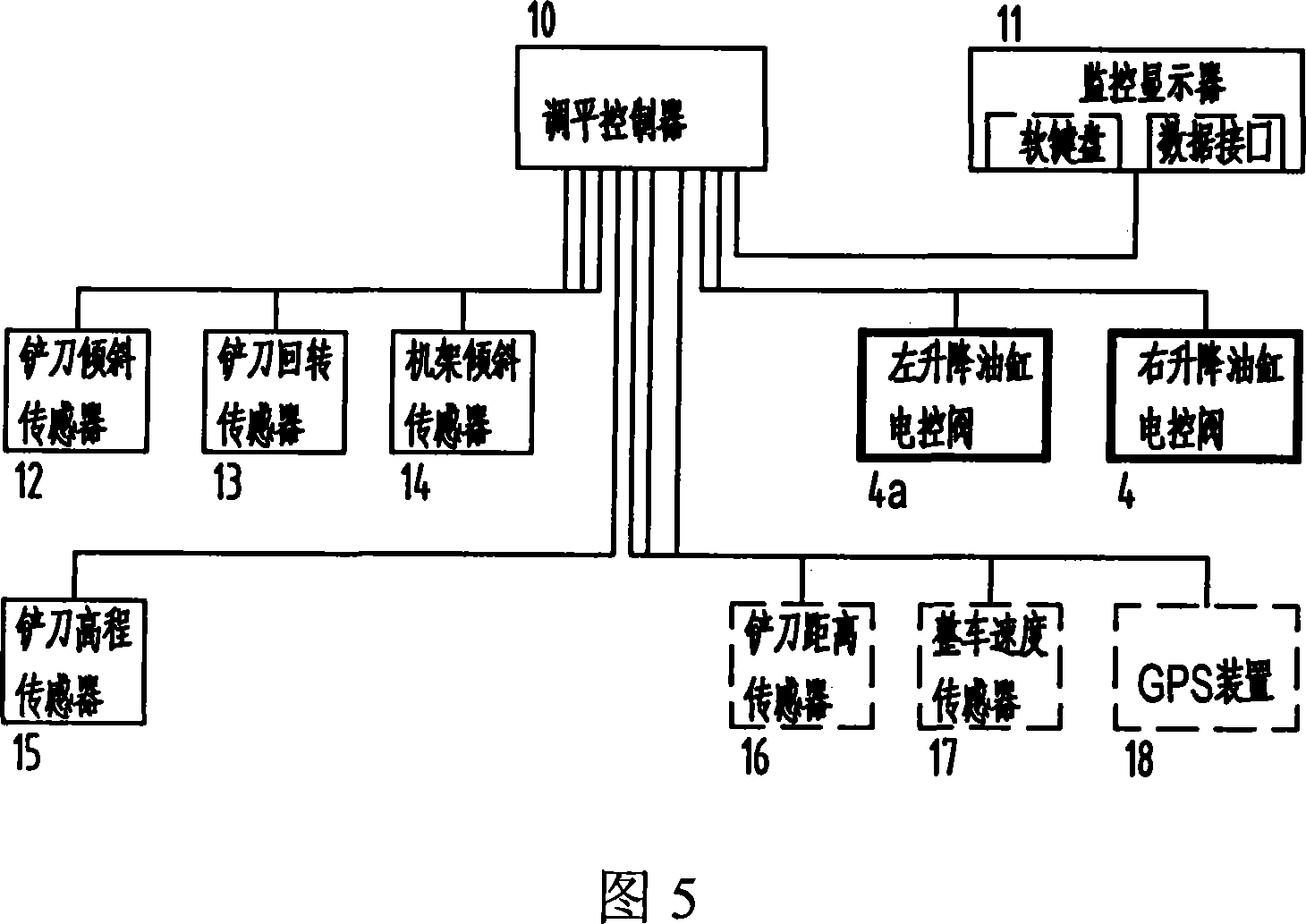

[0086] Fig. 1 is a schematic diagram of the side structure of the motor grader; Fig. 2 is a top view of Fig. 1 . During actual operation, the motor grader controls the spatial position of the scraping blade 9 by adjusting the left and right lifting cylinders 3, 3a of the blade 9, so that the subgrade surface scraped by the blade 9 meets the requirements of engineering construction standards. The blade 9 of the grader is a steel structure. The bottom edge of the blade 9 is a straight line. form a face. When the grader is running horizontally, if the heights of P1 and P2 remain equal, a horizontal plane is formed; if the height difference between P1 and P2 remains unchanged, a slope with a certain slope is formed. In fact, when the grader is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com