Underground tunnel hanging-up assembling supporting construction

A support structure and underground roadway technology, which is applied to underground chambers, tunnels, tunnel linings, etc., can solve the problems of wasting support materials, increasing construction volume, and increasing the size of the roadway section, so as to achieve the reduction of support pressure, The effect of avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

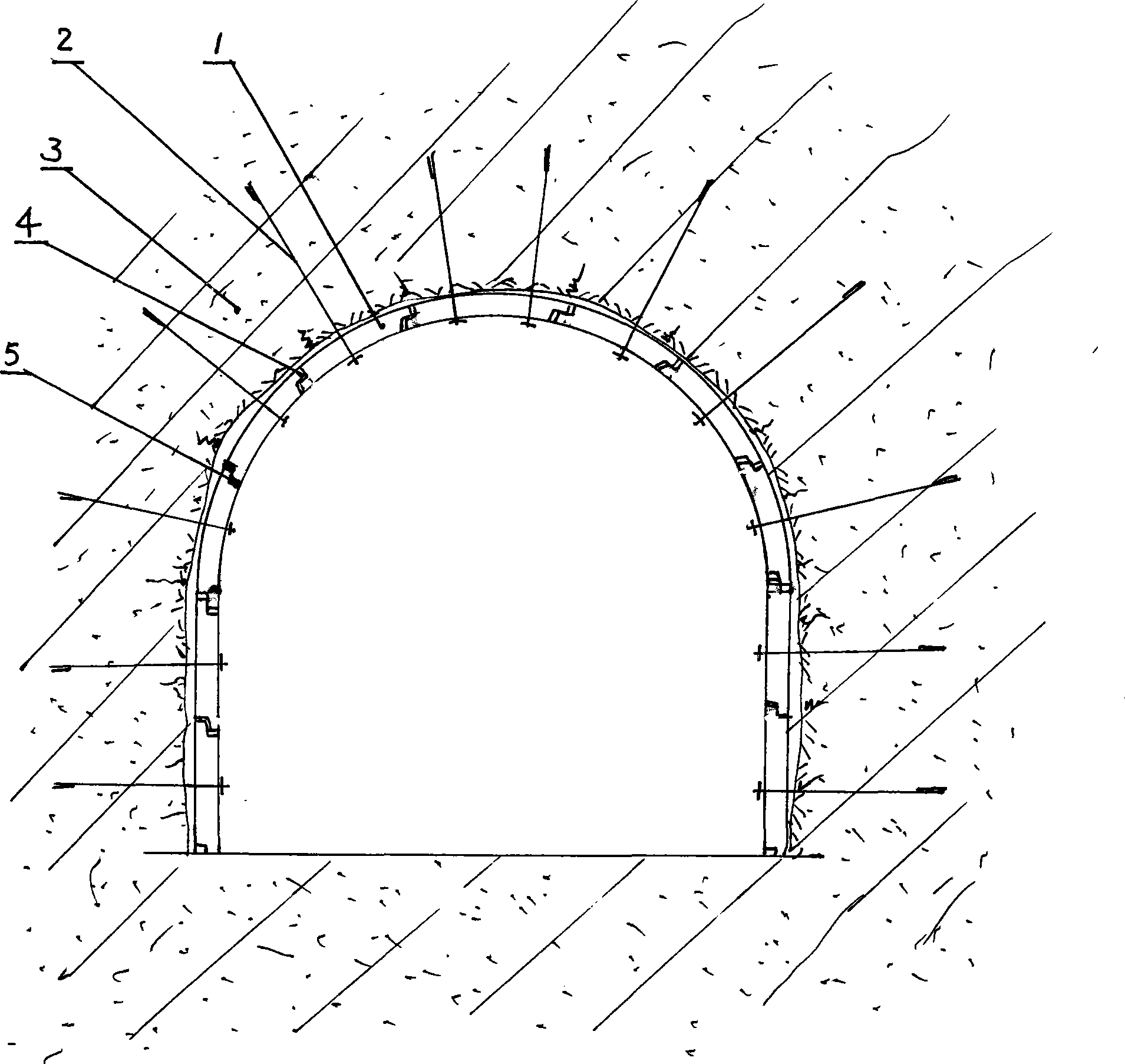

[0020] Such as figure 1 As shown, the hanging assembled support structure of the present invention is assembled into a support layer by twelve support plates 1, and each support plate 1 is hung on the roadway surrounding rock 3 with a bolt 2, and two adjacent supports An expansion joint 4 is left between the guard plates 1, and the width of the expansion joint 4 depends on the deformation of the roadway, and an elastic water-stop strip 5 is pressed in the expansion joint 4.

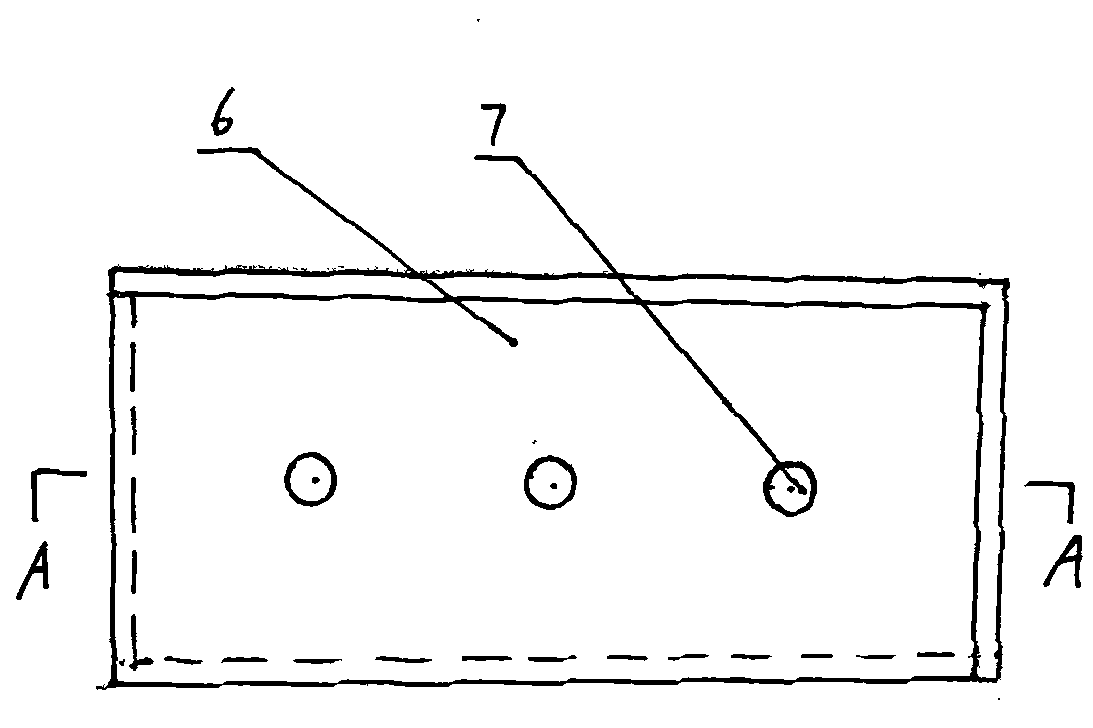

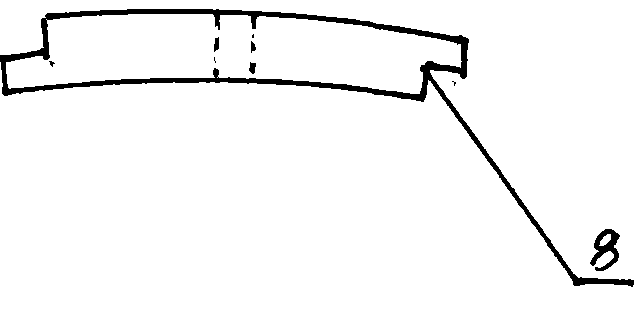

[0021] figure 2 ,image 3, Figure 4 The reinforced concrete slab 6 shown is a rectangular arcuate body, and its arcuate surface should be adapted to the section shape of the roadway. There are three anchor holes 7 on its longitudinal axis for anchor rod hoisting, and its peripheral end face is a stepped end face 8. Lap joints between adjacent ones; structural steel bars 9 are arranged inside to increase strength. Its size should be suitable for manpower moving and installation, generally 400×(600-800)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com