A Modular Gas Central Water Heater Maintenance System

A technology for maintenance systems and water heaters, applied in fluid heaters, lighting and heating equipment, fluid heater control, etc., can solve problems such as difficult gas, leakage, and difficult to observe gas leakage in trachea pipes, so as to reduce the occurrence of fires effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

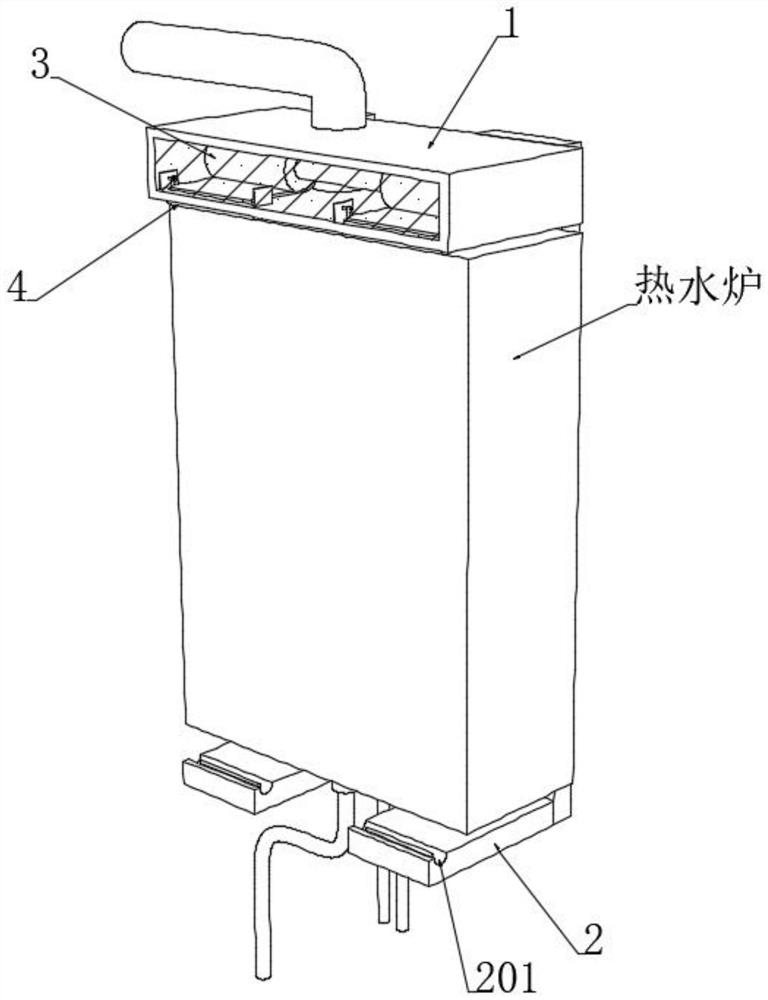

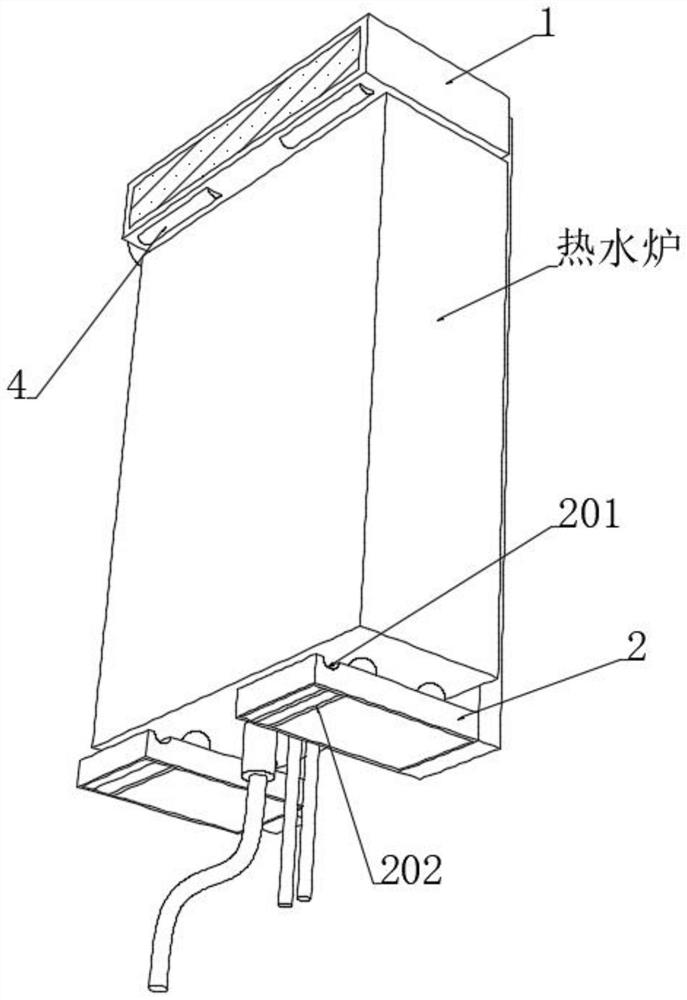

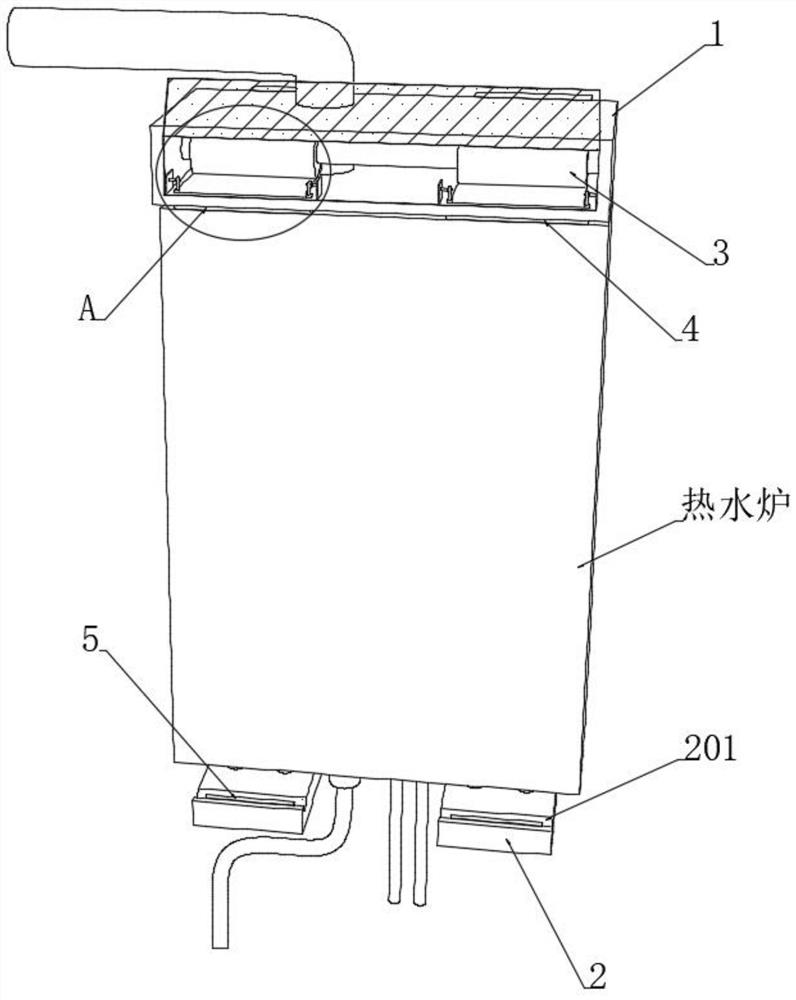

[0045] see Figure 1-2 , a modular gas-fired central water heater maintenance system, including a trigger module 1 installed on the upper end of the water heater, a detection module 2 connected to the inner end wall of the control box through a pair of receiving plates, and the detection module 2 is supported by the hot water Below the furnace, the middle part of the water heater is connected with an air inlet pipe. The inside of the water heater is provided with a burner connected with the air inlet pipe. The bottom of the furnace body is connected with a hot water pipe and a cold water pipe. The cold water pipes are connected to a heat exchanger, and the top of the water heater is provided with an exhaust pipe that penetrates to the outside of the trigger module 1. This is the basic installation structure of the water heater, and will not be described here;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com