Supporting beam structure used for ring cold machine trolley

A technology of supporting beams and ring coolers, applied in the field of supporting beam structures, can solve the problems of large dust and large dust pollution in the surrounding environment, achieve uniform wind speed, eliminate cooling dead zones, and solve the effects of uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

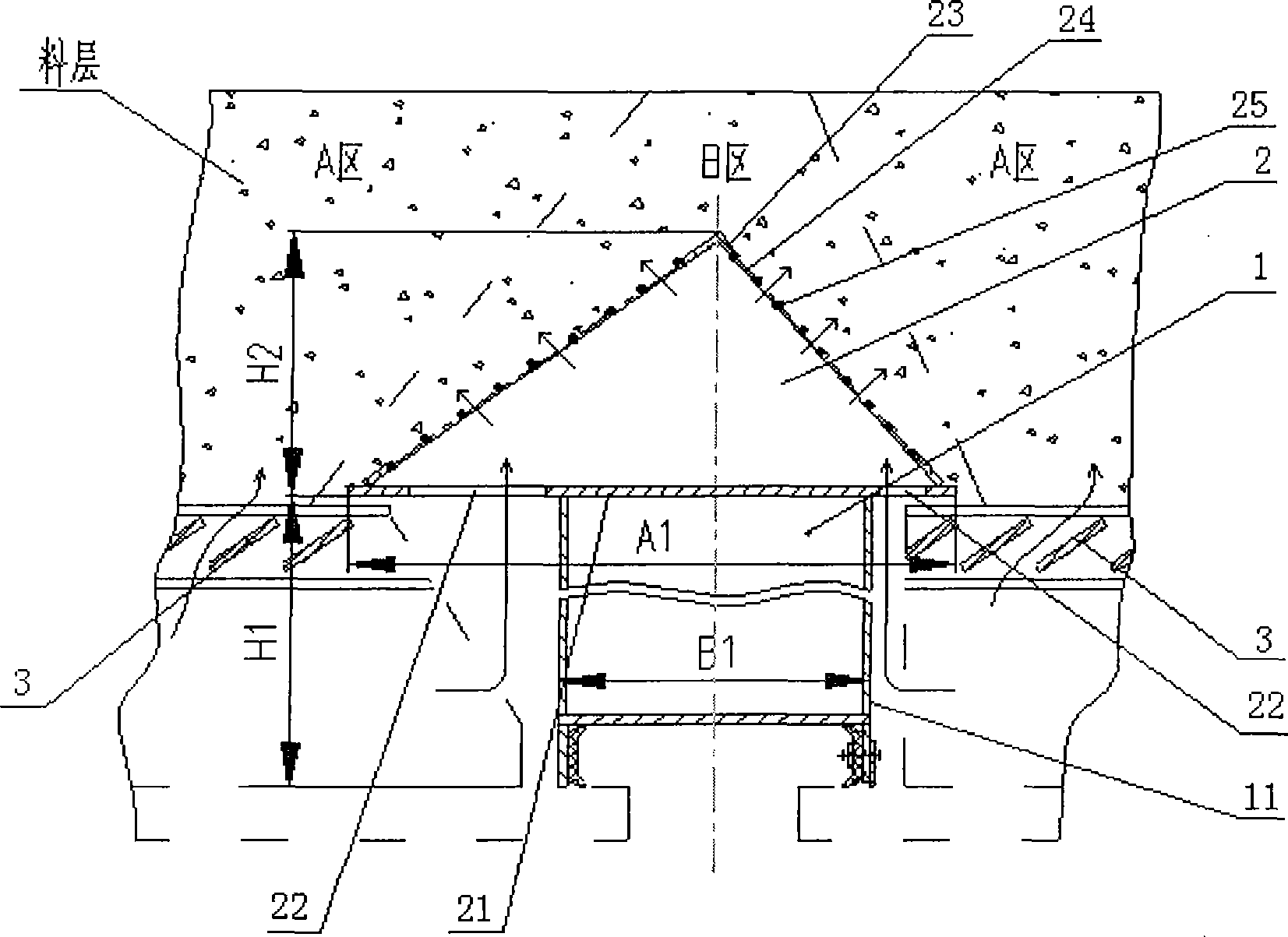

[0010] See accompanying drawing, the present invention has a rectangular beam 1, is constructed with a triangular beam 2 on the top of rectangular beam 1, and the upper wing plate 21 of rectangular beam 1 extends widening to both sides, uses it as the base of upper triangular beam 2, in Rectangular holes 24 are opened on the hypotenuse steel plate 23 of the two waists of the triangular beam 2, and the grate bar 25 is welded into a fixed grate plate with round steel in the rectangular hole 24, and ventilation holes are arranged on the edge extension of the upper wing plate 21 of the rectangular beam 1 22. The side plate 11 of the rectangular beam 1 is used as an integral part of the static seal of the trolley.

[0011] When the structure of the present invention is working, the cold wind enters the material layer A area from under the trolley grate plate through the grate plate 3 according to the front direction, and also enters the abdomen of the triangular beam 2 through the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com