High-temperature continuously temperature measuring system and manufacturing method of temperature measurement pipe

A manufacturing method and a temperature measuring tube technology, which are applied to electric radiation detectors and other directions, can solve the problems of low temperature measurement accuracy, complicated and cumbersome processes, thermal shock rupture of the inner tube, etc., and achieve improved measurement accuracy, good continuous temperature measurement, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

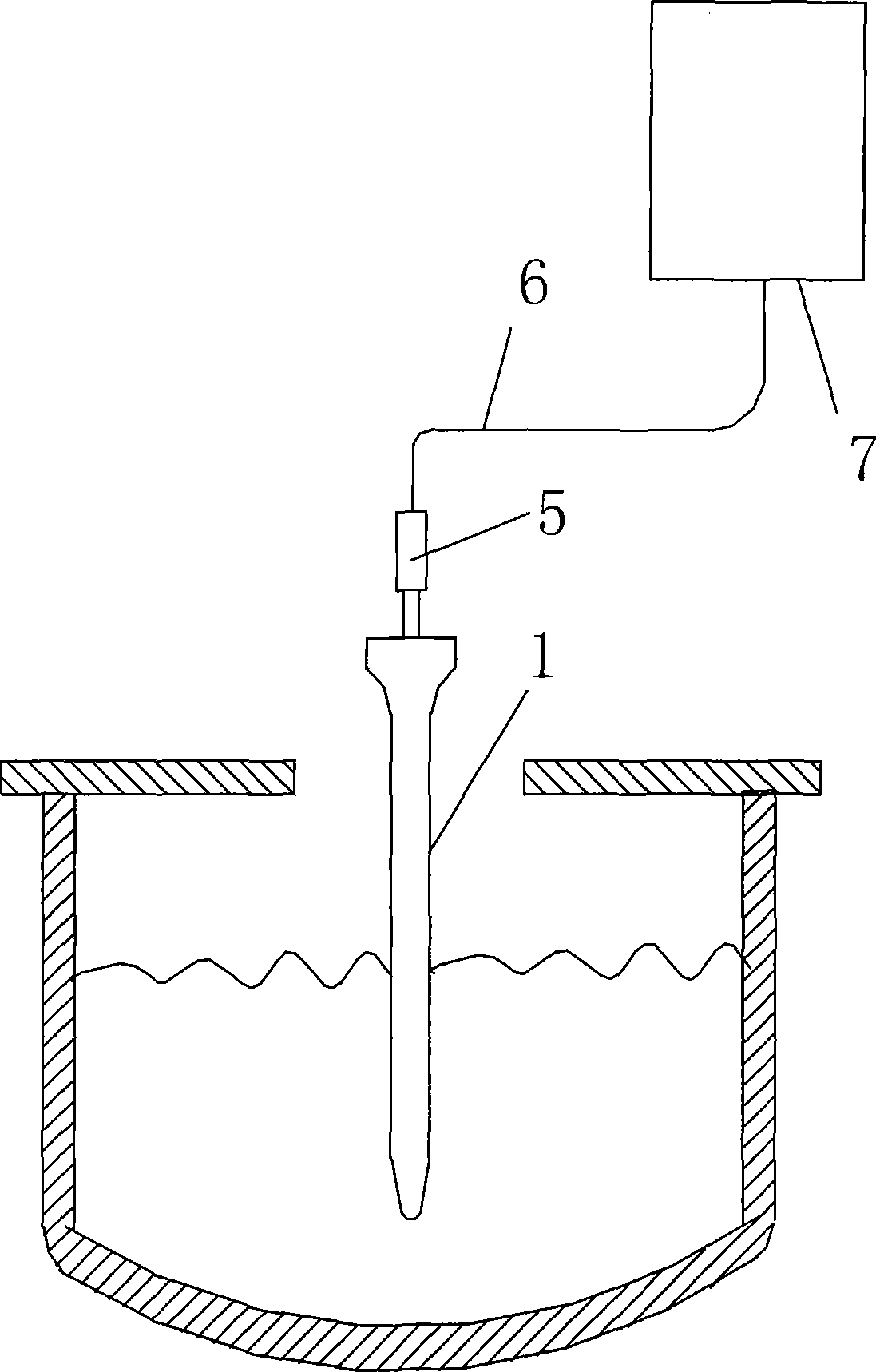

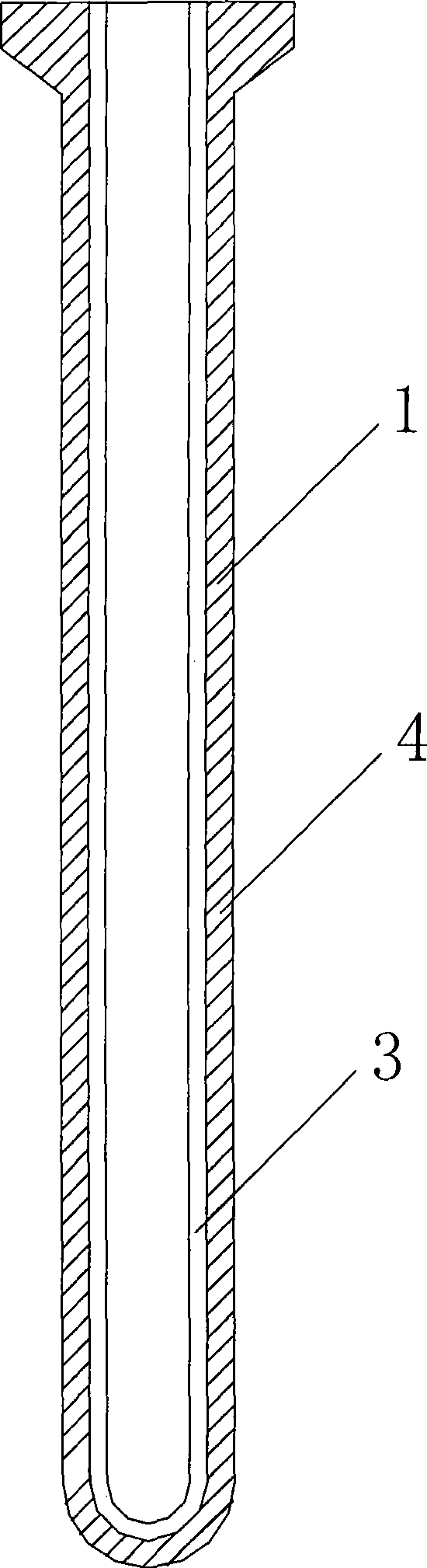

[0036] Such as figure 1 , 2 As shown, the following part of this embodiment describes a high-temperature continuous temperature measurement system: including a temperature measuring tube 1, a light receiving probe 5, a cable 6 and a signal analyzer 7, and the temperature measuring tube 1 includes an inner layer 3 sintered together and the outer layer 4, the outer layer 4 is composed of conventional aluminum-carbon materials, and conventional zirconium-carbon materials or magnesium-carbon materials can also be used. The inner layer 3 is a carbon-free and silicon-free layer, and the formula and weight percentage of the carbon-free and silicon-free layer are respectively For: Magnesium Aluminum Spinel 85%, Light Burnt AL 2 o 3 2%, graphite 1%, boron carbide 5%, clay powder 1%, phenolic resin 6%. The inner layer 3 has a thickness of 4 mm. The temperature measuring tube 1 is connected with the light receiving probe 5 , and the light receiving probe 5 and the signal analyzer 7 ...

Embodiment 2

[0040] Such as Figure 5 As shown, the parts other than the temperature measuring tube 1 of this embodiment are completely the same as those of Embodiment 1, and will not be repeated here. The difference lies in the temperature measuring tube 1. The temperature measuring tube 1 includes an inner layer 3 and an outer layer 4 that are sintered together. The outer layer 4 is composed of conventional aluminum carbon materials, and conventional zirconium carbon materials or magnesium carbon materials can also be used. The inner layer 3 is a carbon-free and silicon-free layer. The formula and weight percentage of the carbon-free and silicon-free layer are: 72% magnesium aluminum spinel, 15% lightly burned AL2O3, 5% graphite, 1% clay, 2% Feldspar, 5% phenolic resin. The inner layer 3 has a thickness of 5 mm. The inner layer 3 and the outer layer 4 are not equal in length, and the length of the inner layer 3 is less than the length of the outer layer 4, because according to known te...

Embodiment 3

[0044]The structure of the high-temperature continuous temperature measurement system of this embodiment is the same as that of the high-temperature continuous temperature measurement system of Embodiment 1, and the difference from Embodiment 1 is that the formula and weight percentage of the inner layer of this embodiment are: 70% magnesium-aluminum spinel Stone, 15% lightly burned AL 2 o 3 , 4% graphite, 2% boron carbide, 2% glass frit, 1% feldspar, 6% phenolic resin. The inner layer 3 has a thickness of 3 mm.

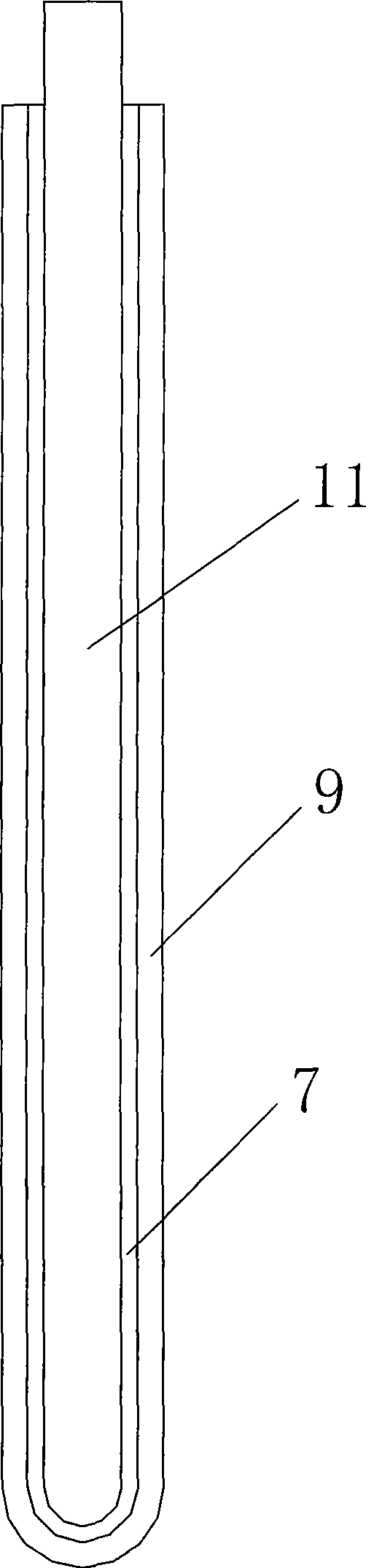

[0045] The following part of this example describes the method of manufacturing the thermometric tube, as image 3 , 4 As shown, the steps are:

[0046] Mandrel 11, large rubber mold 10 and small rubber mold 9 are first prepared, which will include 70% magnesia-aluminum spinel and 15% lightly burned AL 2 o 3 , 4% of graphite, 2% of boron carbide, 2% of glass frit, 1% of feldspar, and 6% of phenolic resin are mixed evenly and processed into mud. Then the mud is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com