Multifunctional quick replaceable double-acting clamp paw bench vice

A multi-functional, bench vise technology, applied in the bench vise, machining and cutting machine tool clamping workpiece field, can solve the problems of involuntary processing, unreliable clamping, complex manufacturing process, etc., to reduce the number of special The effect of process equipment, cost reduction, and shortened development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

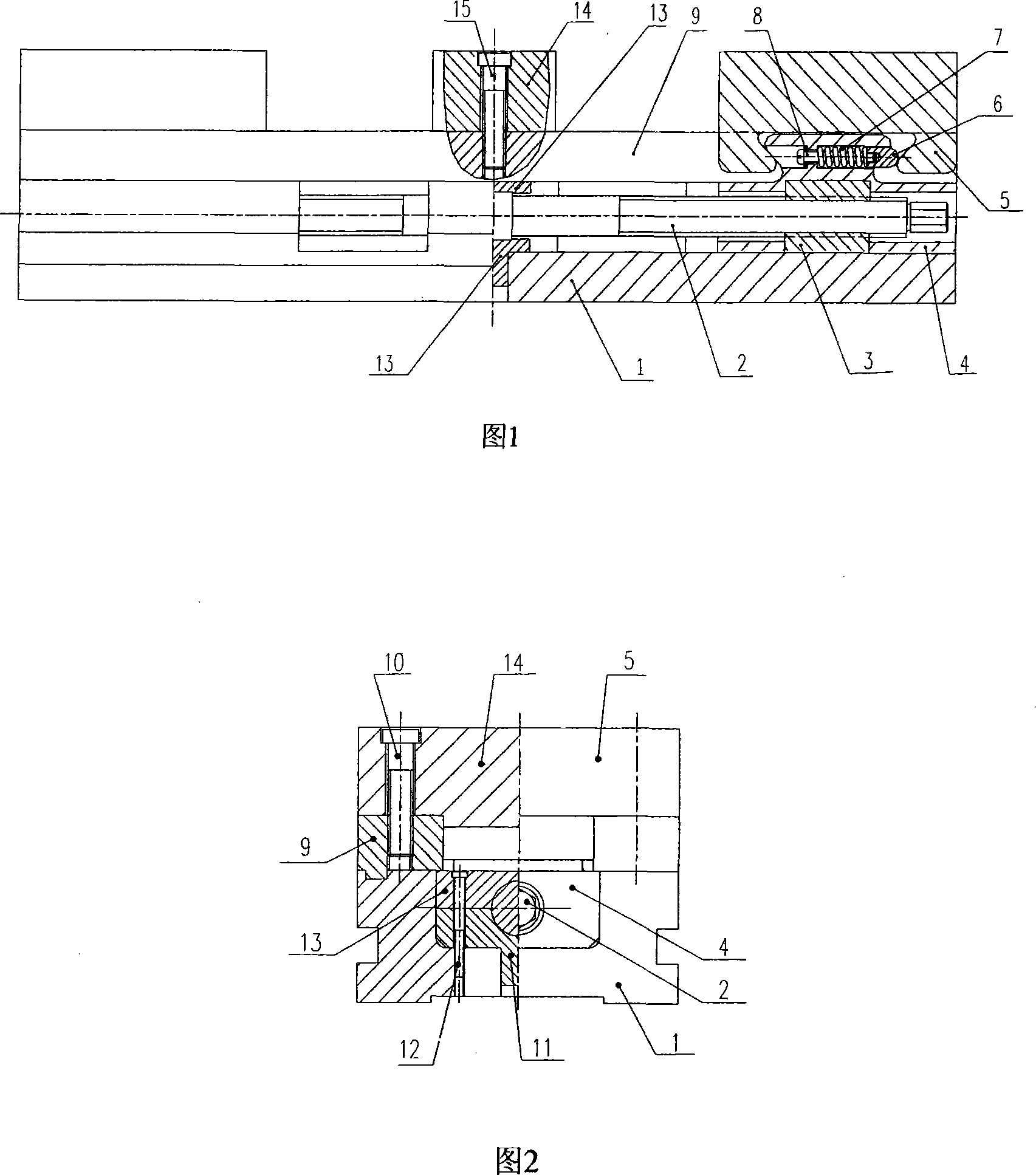

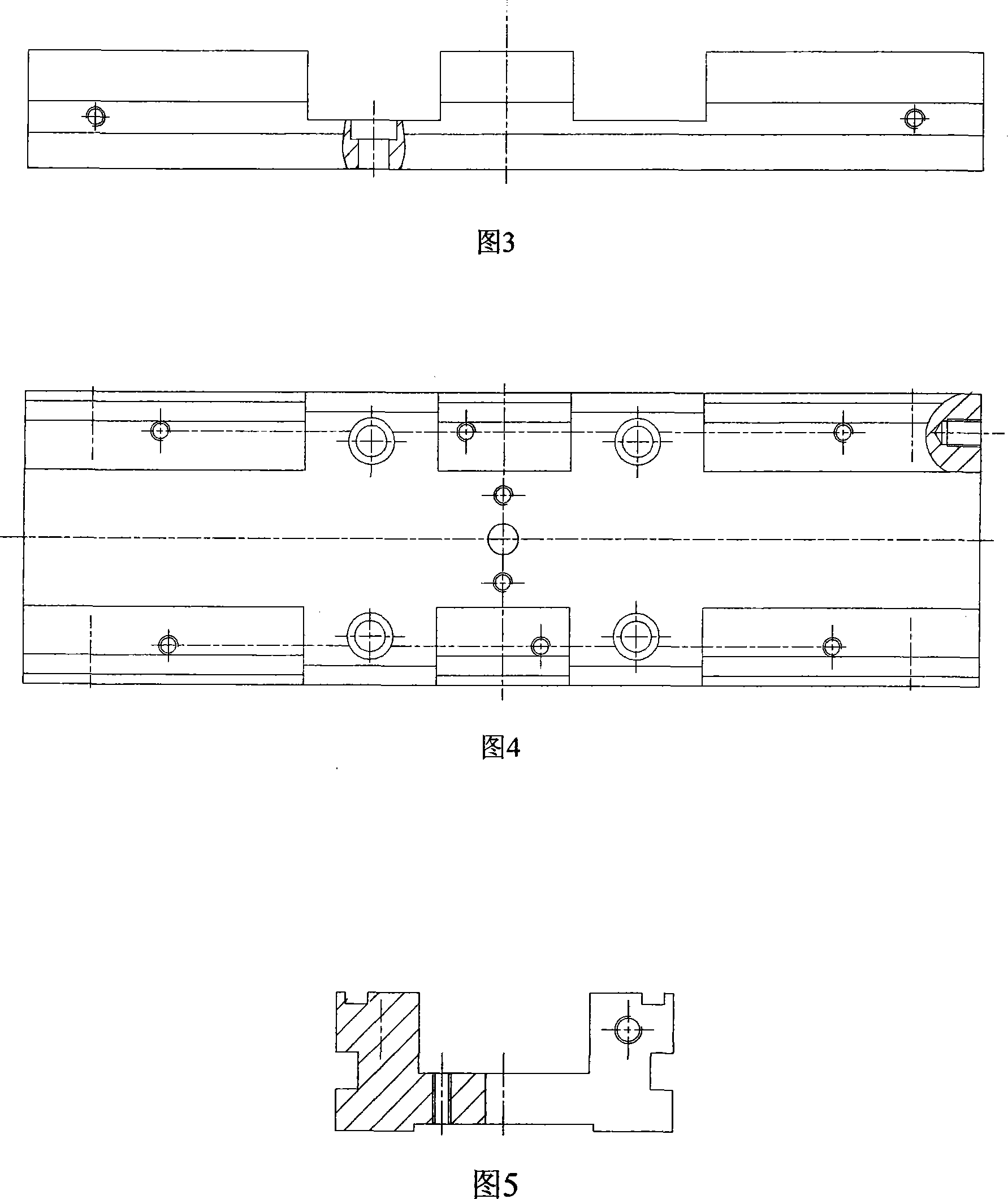

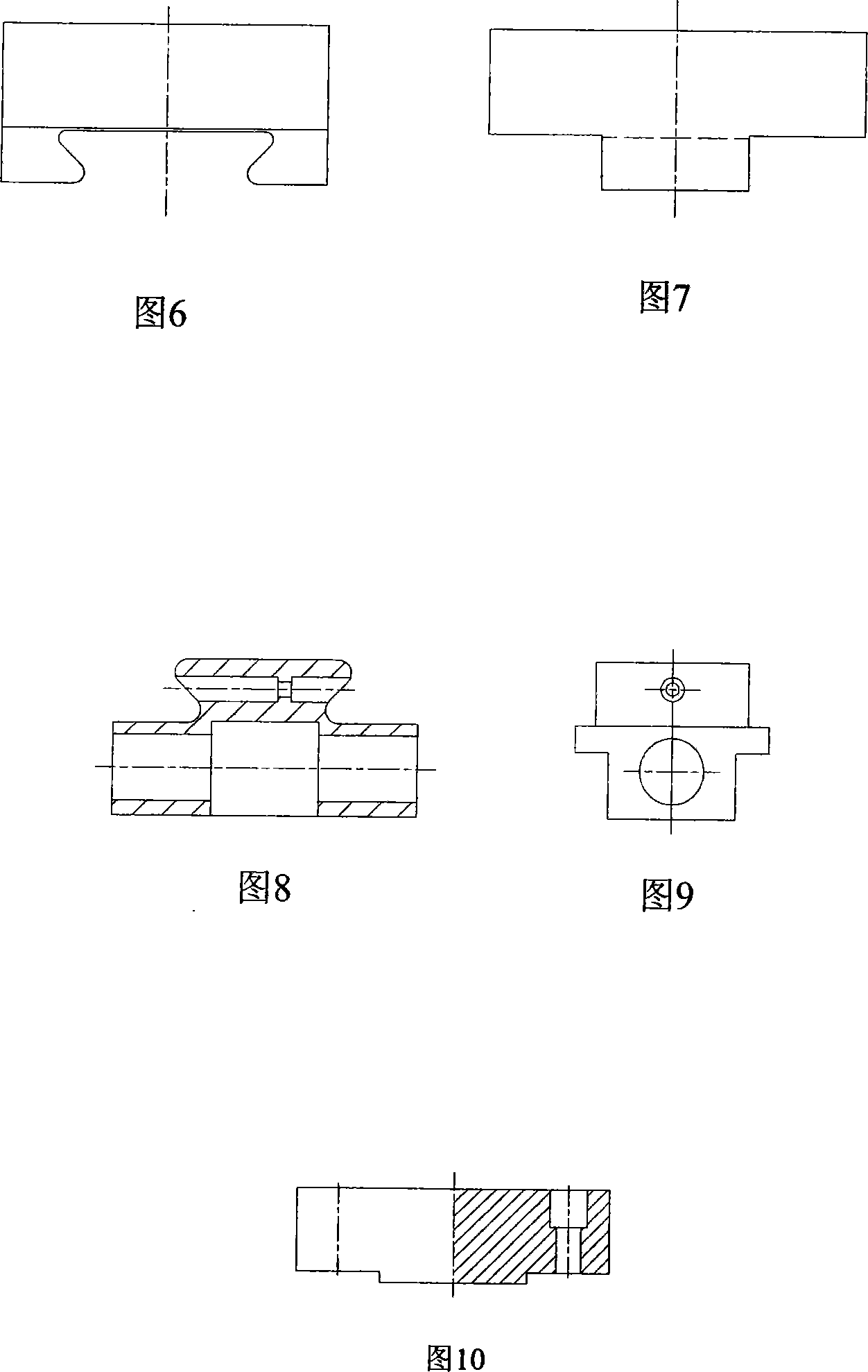

[0027] As shown in Figure 1 and Figure 2, the multifunctional quick-change double-action jaw bench vise includes a clamp body 1, a lead screw 2, a screw nut 3, a driving block 4, and a movable jaw 5, wherein the clamp body 1 and the lead screw 2, one piece each, two nuts 3, two driving blocks 4, and two moving claws 5; as shown in Figure 3 to Figure 5, the clamp body 1 is a rectangular parallelepiped structure, and the driving block 4 and the movable claw are arranged on the clamp body 1 On the surface of 5, there are slideways for driving block 4 to move and two guide rail grooves for installing guide rail 9, and screw holes, pin holes or pressure plate grooves for installing on the machine tool workbench are provided on the other five surfaces; There is a convex edge corresponding to the guide rail groove of the clamp body 1 on the 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com