Method for calibrating drying box for determining tobacco moisture and method for determining tobacco moisture

A moisture and tobacco technology, applied in the field of moisture determination in tobacco, can solve problems such as inconsistency of moisture test results, and achieve the effect of solving errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Preparation of standard moisture samples: Take 1000 grams of finished cut tobacco, grind it into tobacco powder of about 80 meshes through a grinder, and balance the batch of samples in a constant temperature and humidity box with a humidity of 60±2% and a temperature of 22±1°C for 96 hours. Get 30 grams of samples by quartering method and divide into three parts and measure according to the standard method of current moisture determination in the oven calibrated by thermometer, and its moisture content is respectively 12.1%, 11.9%, 12.0%. Therefore, we determined this batch of samples as standard water samples with a moisture content of 12.0%. Divide the standard water sample into several 50-gram samples, and put them in special pop-top cans after being balanced in a constant temperature and humidity box with a humidity of 60±2% and a temperature of 22±1°C for 24 hours. %, sealed and stored under constant temperature and humidity conditions at a temperature of 22±1°C. ...

Embodiment 2

[0014] Take 30 grams of the standard sample in Example 1 from the sealed pop-top can at each use, evenly divide it into 3 parts, and check the oven of the quality supervision and inspection station repeatedly until the oven measures the standard moisture sample value at 12.0 ± 0.1% within.

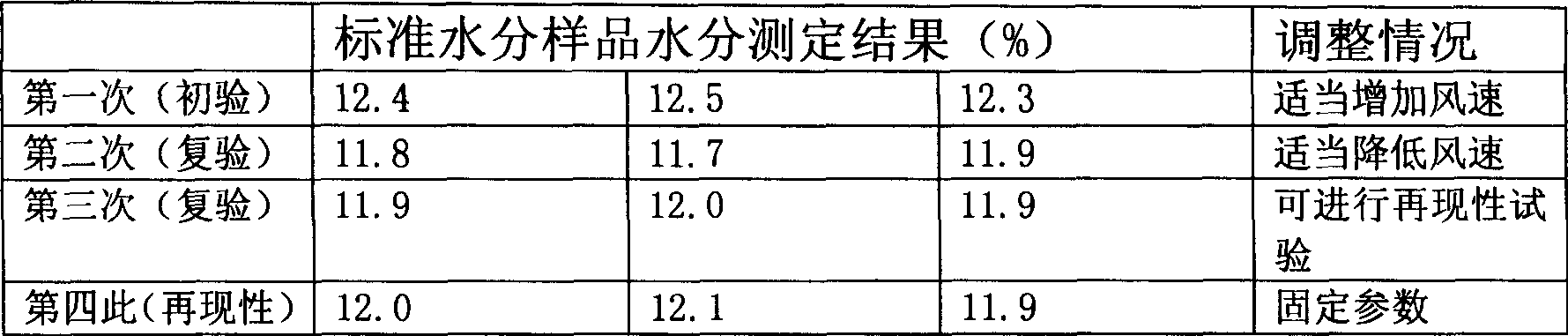

[0015] The verification results are as follows:

[0016]

[0017] After more than three checks and one reproducibility test, the oven was determined to have a moisture determination reliability greater than 95%. It can be used as an oven for measuring the moisture content of tobacco products in process and calibrating online moisture instruments.

Embodiment 3

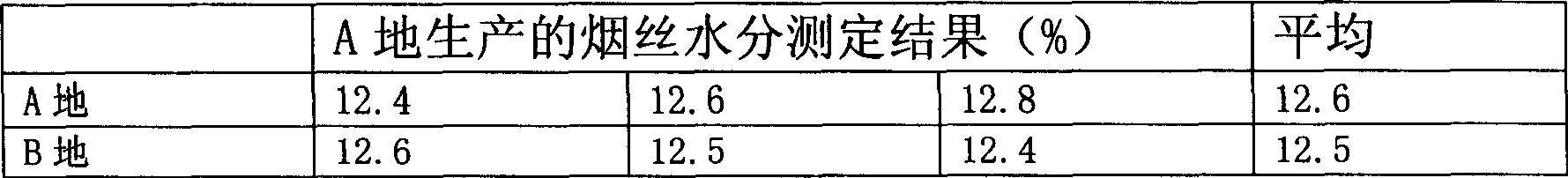

[0019] Each time with the standard sample in Example 1, use the method in Example 2 to check the ovens at the two processing points A and B several times until the oven measures the standard moisture sample value within 12.0 ± 0.1%. The moisture content of cut tobacco produced in A is tested in A and B. The result is as follows:

[0020]

[0021] Due to the long-distance transportation of the shredded tobacco processed in A, the moisture will be lost to a certain extent, which is very normal, and it also shows that the standard moisture sample has played its due role in the calibration oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com