Contraposition structure of plasma display panel

A display panel and plasma technology, applied in the direction of solid cathode parts, discharge tube/lamp manufacturing, electrical components, etc., can solve the problems of increasing alignment error, alignment mark deformation, and deviation from the original position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

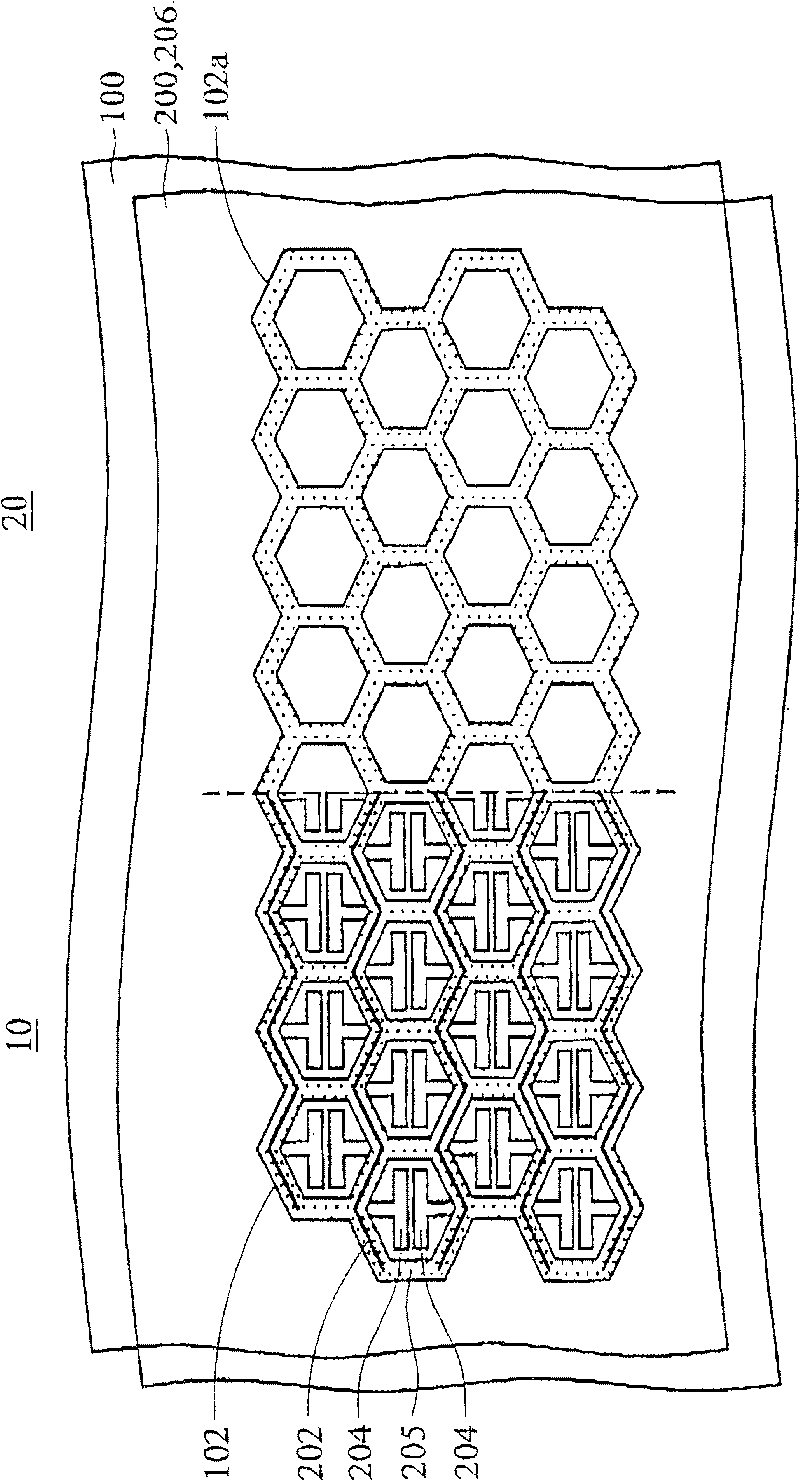

[0032] see figure 1 , the plasma display panel includes a rear substrate 100 and a front substrate 200 oppositely disposed. The rear substrate 100 and the front substrate 200 are divided into a display area 10 and a non-display area 20 .

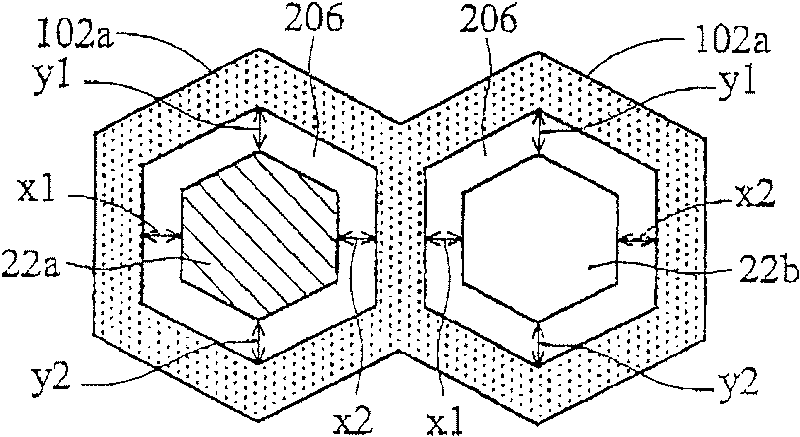

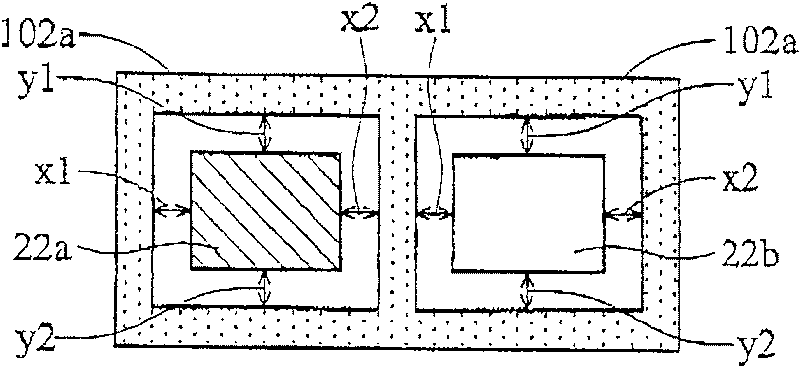

[0033] The hexagonal barrier rib structures 102 and 102a are respectively formed on the display area 10 and a non-display area 20 of the rear substrate 100 . Each hexagonal barrier structure is adjacent to each other to form a honeycomb barrier structure, such as figure 1 shown. It should be noted that the hexagonal barrier structures 102 and 102a can be closed or have openings at the corners for gas injection and exhaust. In the display region 10 , the space defined by the hexagonal barrier rib structure 102 serves as a discharge space. A plurality of address electrodes (not shown) are parallel to each other and disposed on the rear substrate 100 below the hexagonal barrier rib structures 102 and 102a.

[0034] A plurality of auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com