Multiple film glue stopper neck whole board placing and sucking-off device

A technology of laminating glue and control devices, which is applied to household components, household appliances, and other household appliances. It can solve problems such as finger burns, lower surface temperature, and long storage time, and achieve product quality assurance, small temperature changes, and Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

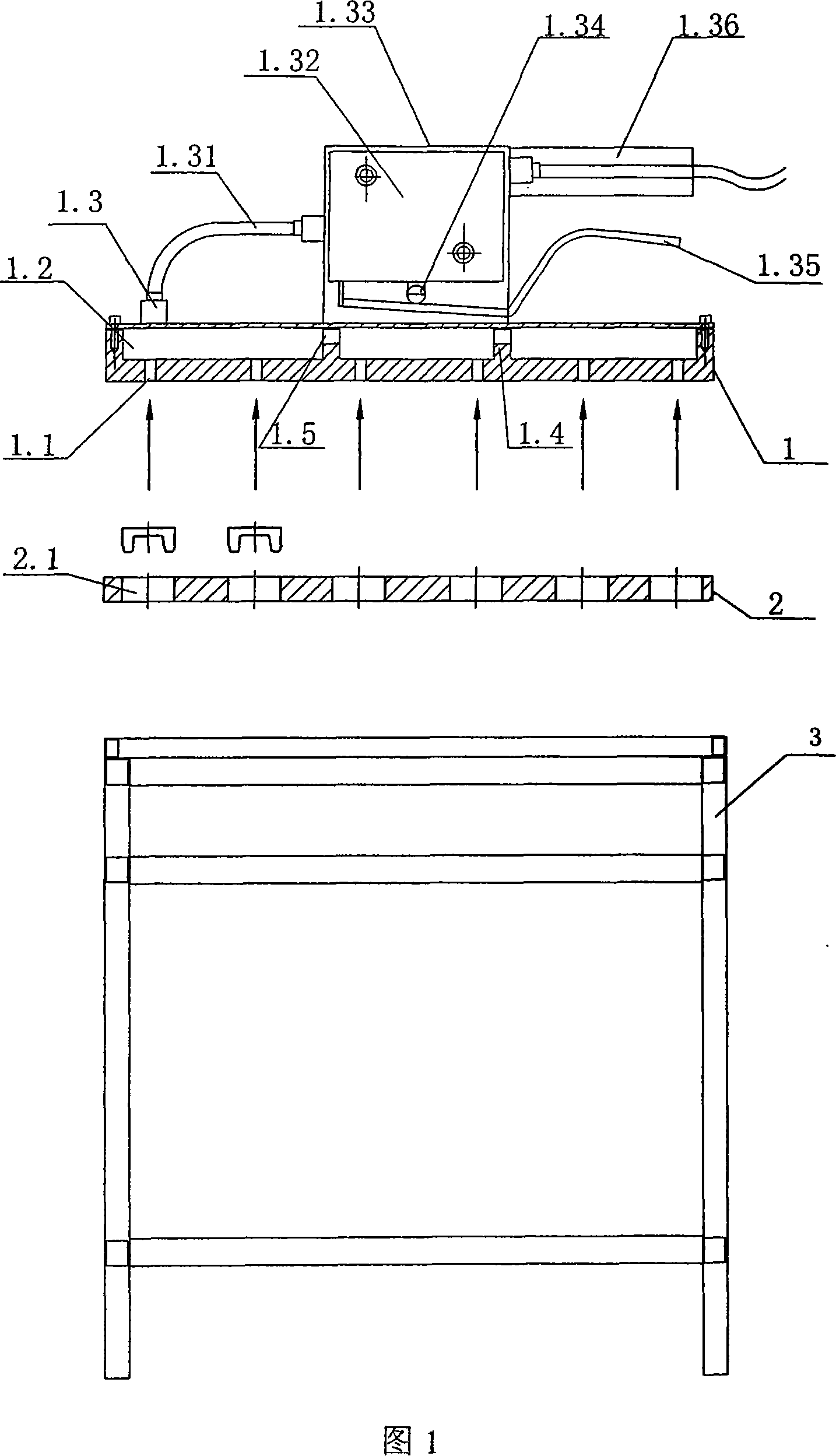

[0011] Referring to Fig. 1 , the present invention is a device for placing and sucking out the neck of a laminated rubber stopper. The device is mainly composed of a template 2 and a suction block 1 .

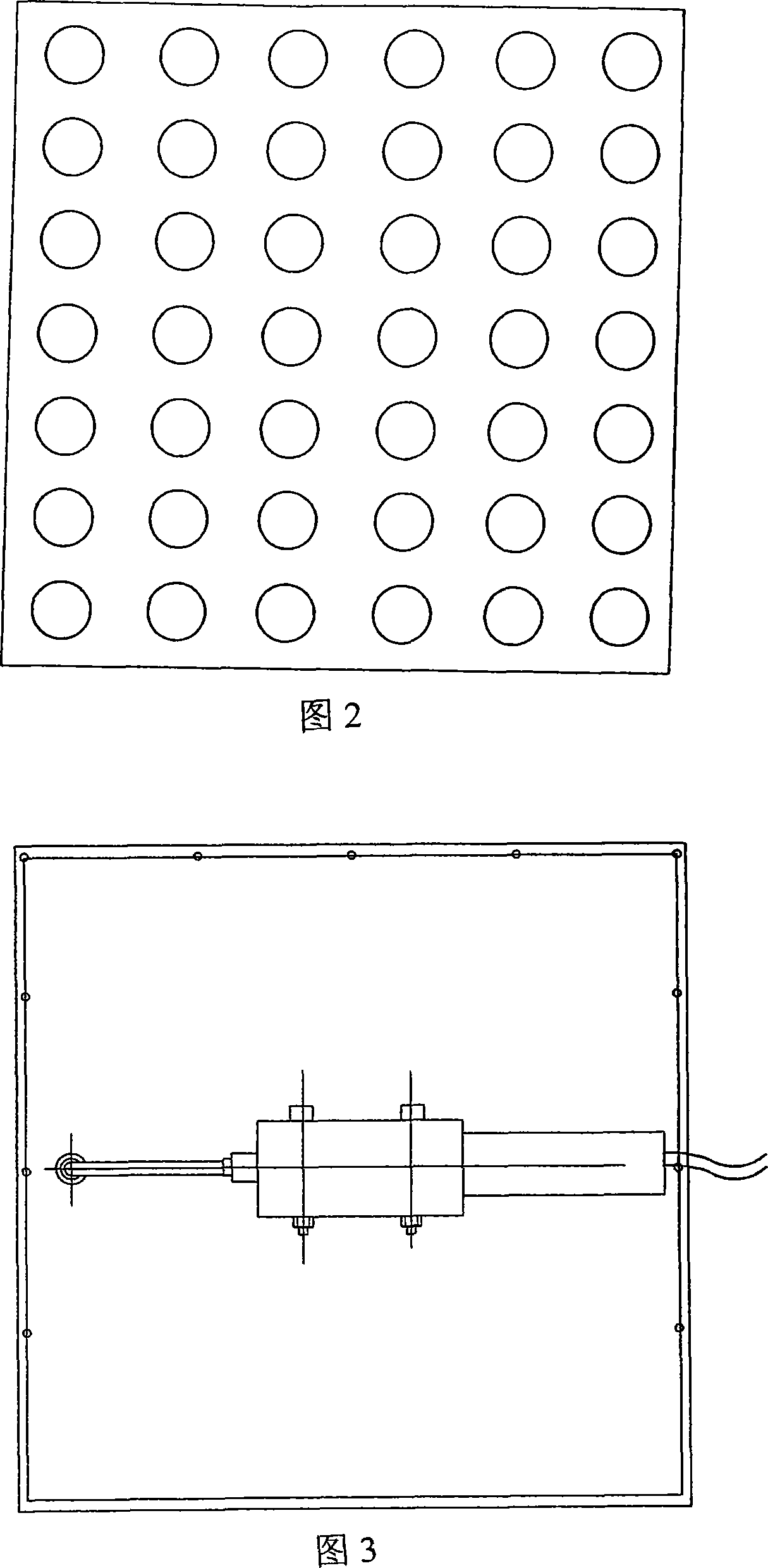

[0012] The template 2 is square, and several mold holes 2.1 corresponding to the second vulcanization mold cavity of the rubber stopper are evenly distributed on the template 2, as shown in Fig. 2 .

[0013] The suction block 1 has a square hollow structure, and the abdominal cavity 1.2 of the suction block 1 is provided with a reinforcing rib 1.4, and the reinforcing rib 1.4 is provided with a ventilation hole 1.5, and the ventilation hole 1.5 communicates with each other between the abdominal cavity units separated by the reinforcing rib 1.4 . One or more ribs can be provided to enhance the fastness. The bottom end surface of the suction block 1 is evenly distributed with several suction holes 1.1 corresponding to the mold holes 2.1 of the template 2, the suction holes 1.1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com