Electric machine load simulate mechanism

A load simulation and load simulation technology, applied in the direction of motor generator testing, etc., can solve the problems of inconvenient measurement of various parameters of the motor, poor versatility, complex structure, etc., to achieve simple structure, good versatility, and convenient measurement data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

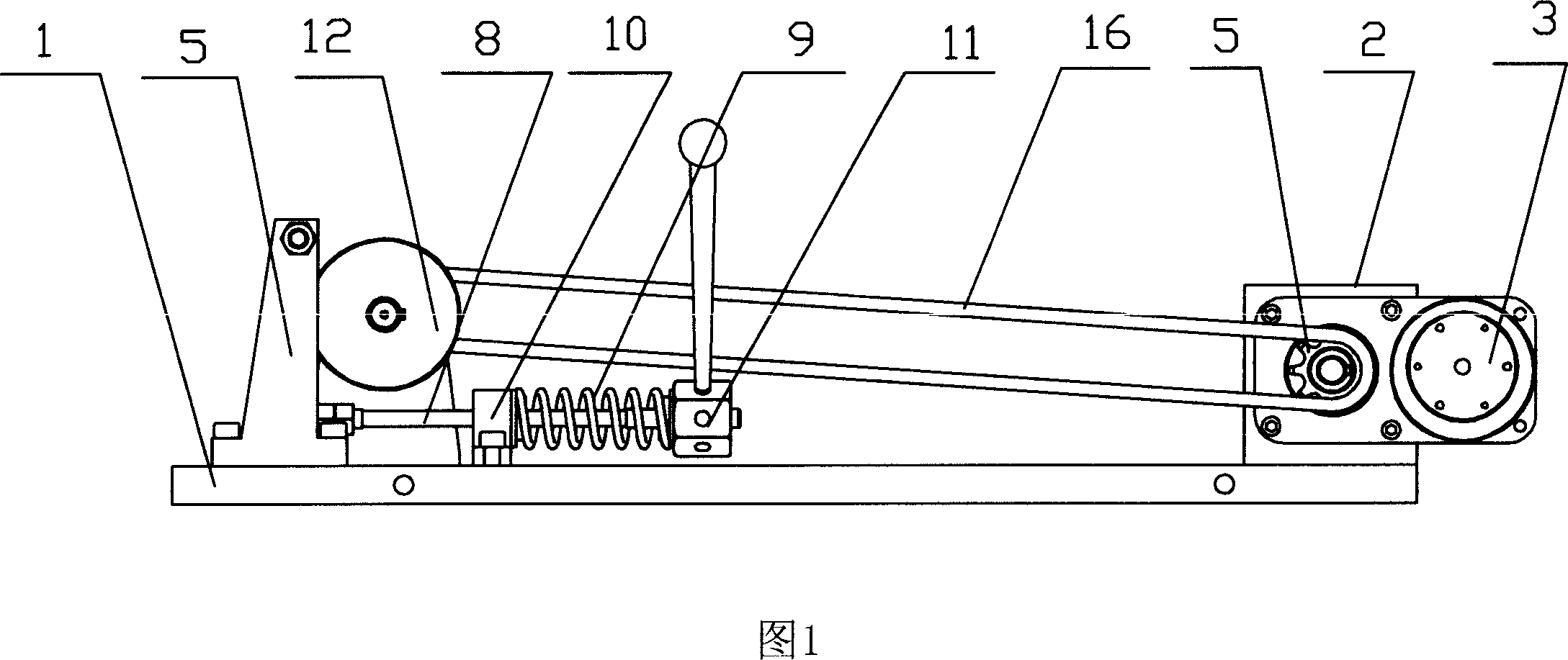

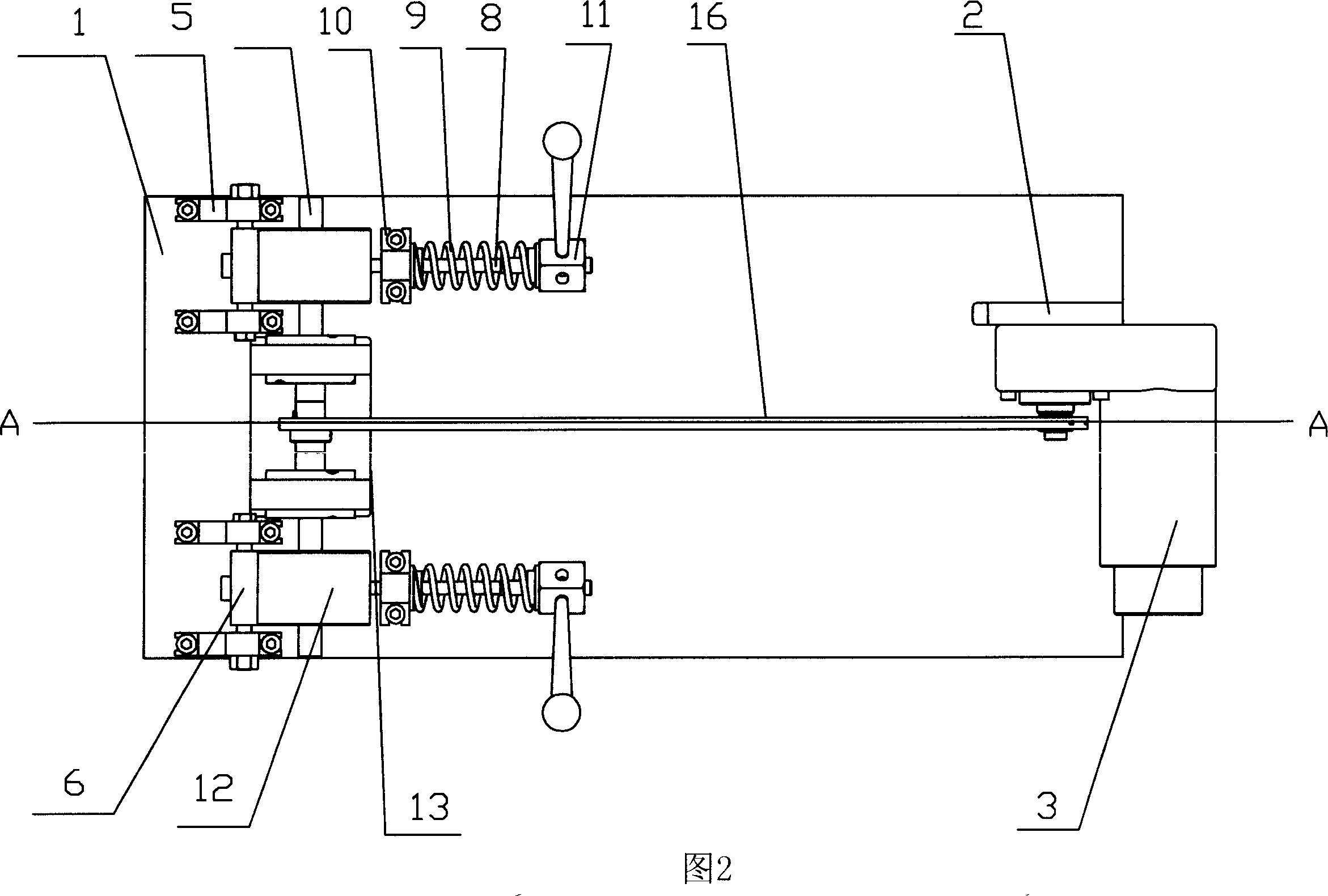

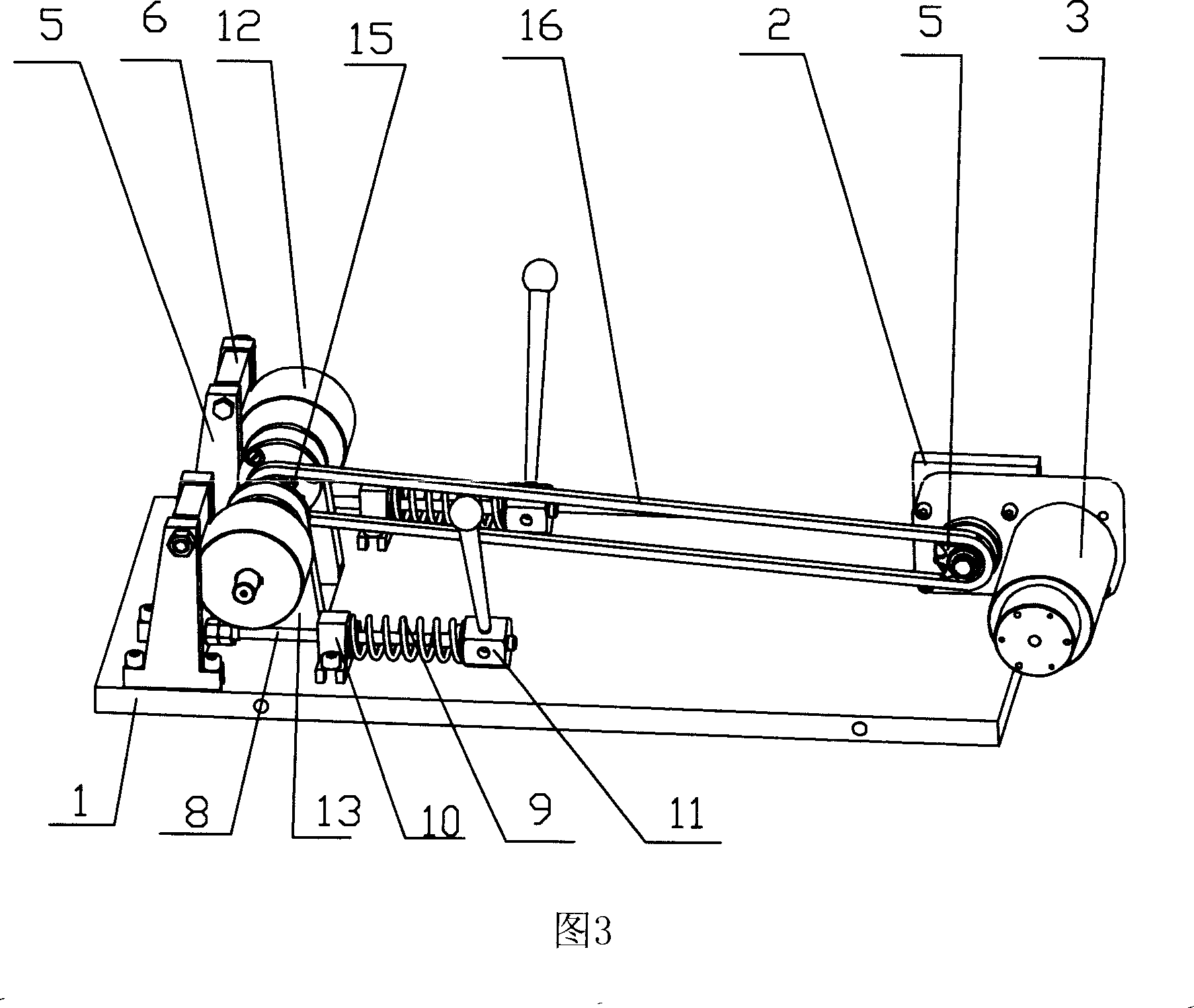

[0018] Example 1: As shown in Figures 1 and 2 and 3, a motor load simulation mechanism includes a bottom plate 1. A motor support block 2 is provided at one end of the bottom plate 1, and a motor to be tested 3 is fixed on the motor support block 2. One end of the output shaft of the test motor 3 is provided with a sprocket 4, the motor 3 to be tested is set on the center line AA of the bottom plate, and the other end of the bottom plate 1 is provided with an analog load device. The analog load device includes a support frame 5 and a support frame 5. Fixed on the bottom plate 1, the upper end of the support frame 5 is hinged with a friction plate fixing block 6 through a pin shaft, the friction plate fixing block 6 is bonded with a friction plate 7, and the lower end of the friction plate fixing block 6 is connected with a pressing mechanism. The pressing mechanism includes a pressing rod 8. One end of the pressing rod 8 is connected to the fixed block of the friction plate 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com