Bag extrusion device of the hanging bag type centrifugal machine

A centrifuge and hanging bag type technology, applied in the field of bag extrusion device, can solve the problems of tearing the filter bag, difficult to lift the filter bag, limited use range of the hanging bag type centrifuge, etc., and achieve the effect of expanding the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

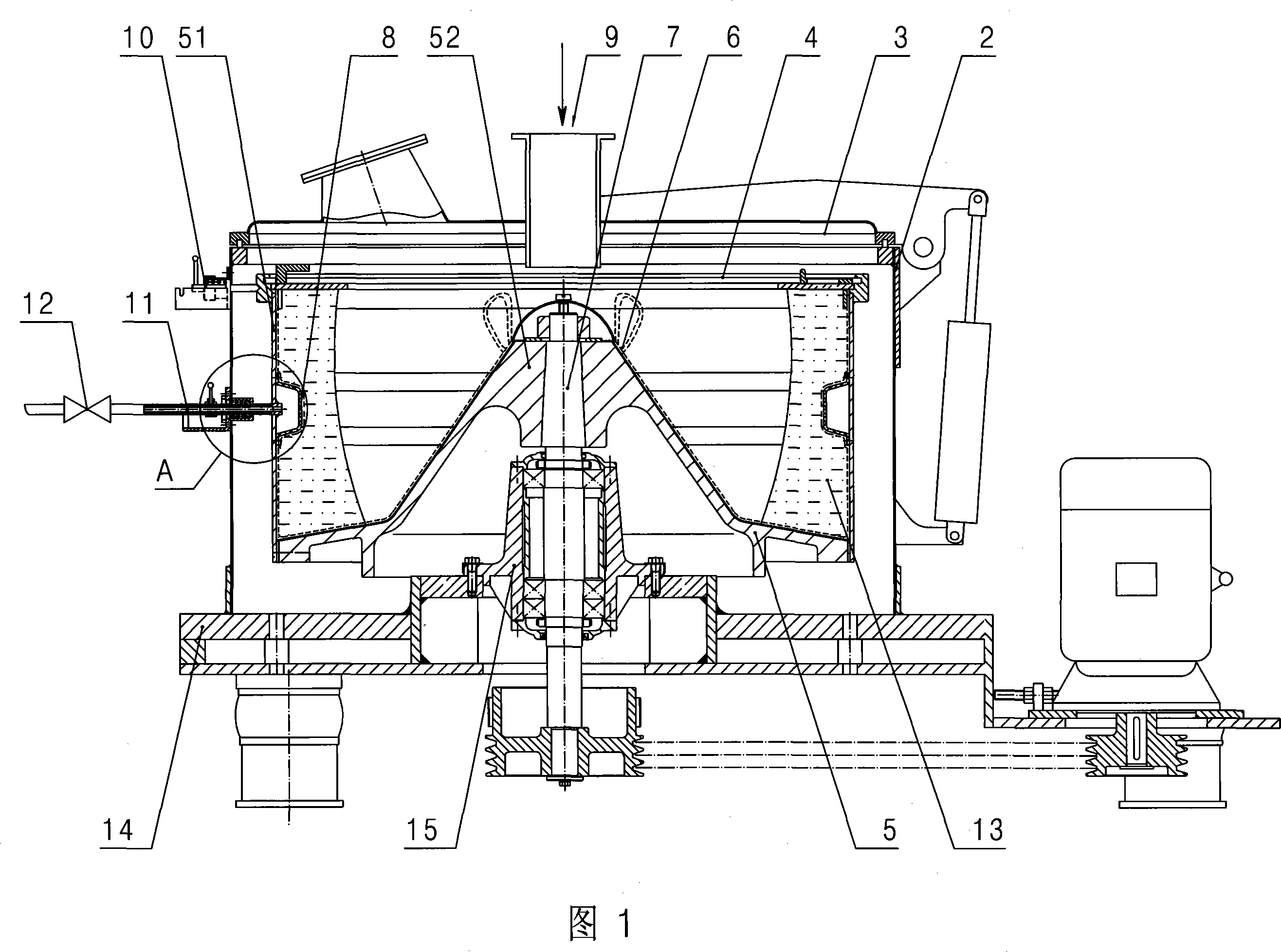

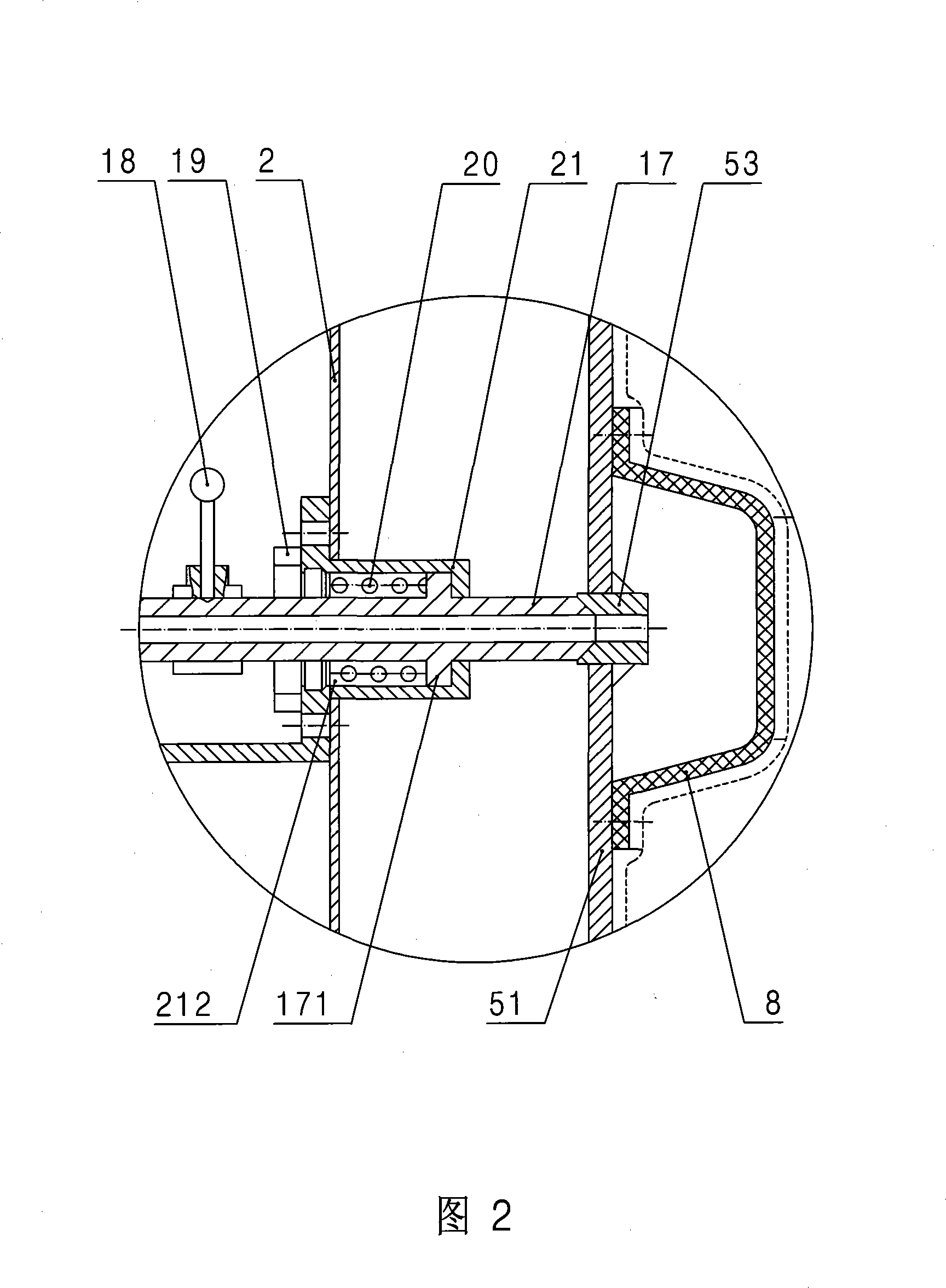

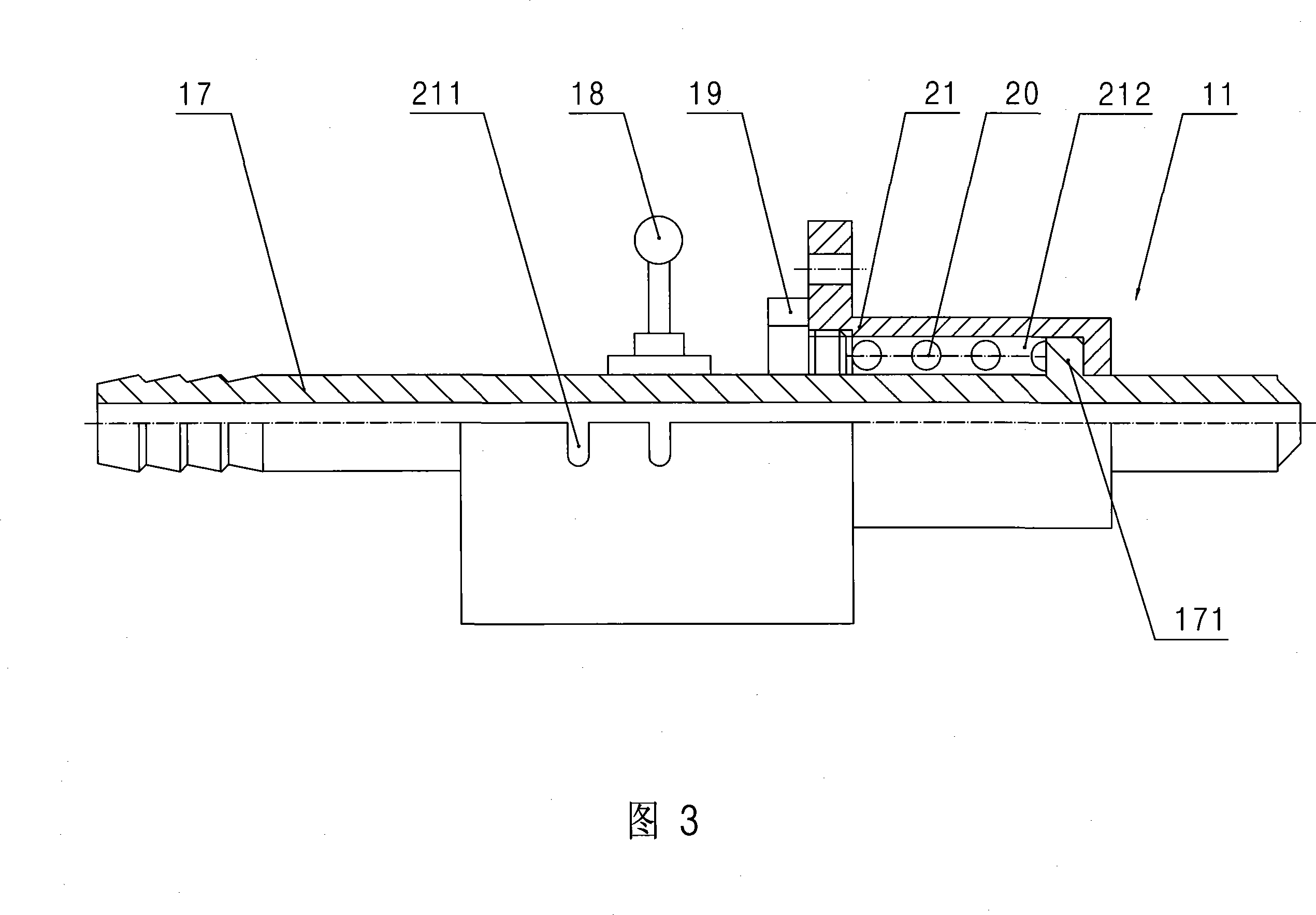

[0014] As shown in FIG. 1 , the bag squeezing device in the hanging bag centrifuge of the present invention includes: a drum 5, and the drum 5 further includes: a drum body 51 and a drum bottom 52, and the drum bottom 52 is arranged on the On the main shaft 7, the main shaft 7 is movably arranged on the base 14 through the bearing seat 15, a filter bag 6 is arranged in the drum 5, and a semi-open annular air bag 8 is arranged on the inner wall of the drum body 51. The specific setting method is: The place where the annular air bag 8 and the inner wall of the drum body 51 are attached is pressed by a press ring with screws. filter holes, so that the annular air bag 8 and the inner wall of the drum body 51 together form an air cavity; the air inlet 53 of the annular air bag 8 is penetrated in the drum body 51—see FIG. 2, the annular air bag 8 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com