Lorry body suspension conveying line

A technology for railway wagons and conveyor lines, which is applied to manual conveying devices, motor vehicles, transportation and packaging, etc. It can solve the problems of inconvenient, inconvenient transfer of tooling, electric welding and noise, etc., and achieves low noise, convenient transfer of tooling, and easy lifting safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

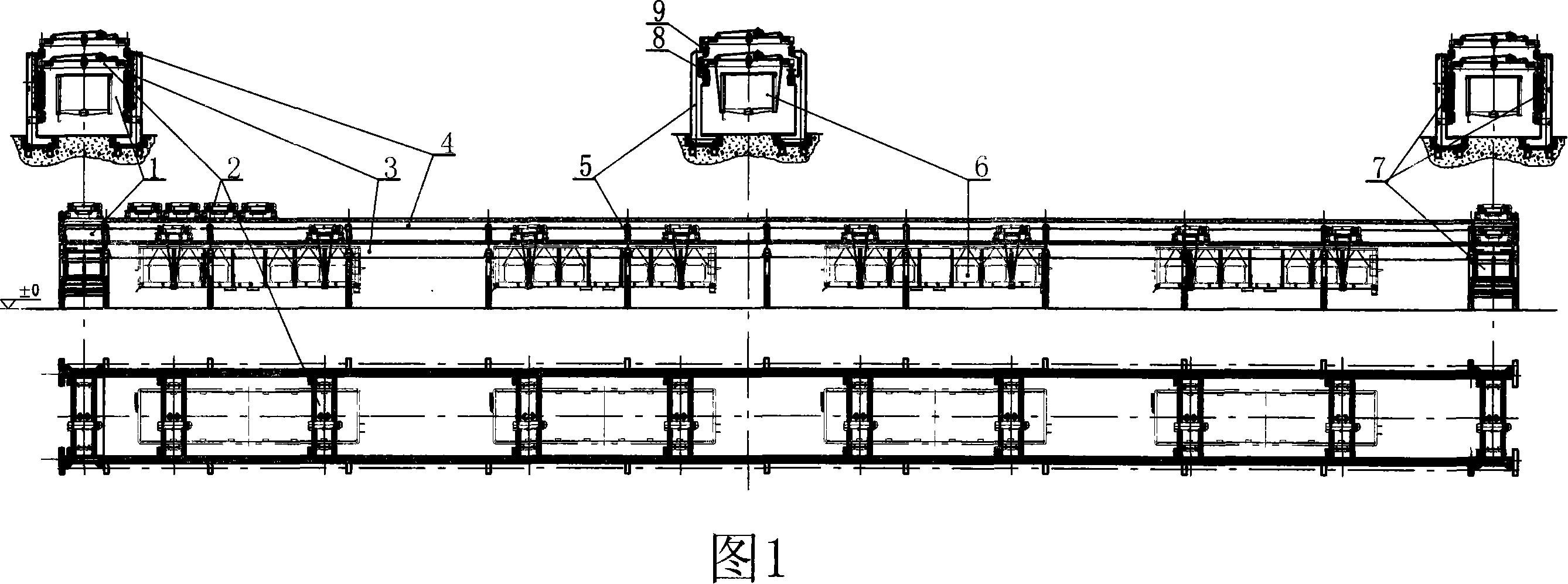

[0008] Two supports are established on the column 5 of the railway freight car body suspension conveyor line, the upper track 4 is installed on the upper support and the return track is installed, and the lower track 3 is installed on the lower support and is the working track. The car body crane running car 2 walks on the working track 3, and two car body crane running cars lift a car body 6. There are multiple car body cranes on the working track at the same time, and multiple car bodies are hoisted to walk and work. When the car body 6 enters the last station of the car body overhaul suspension conveying line, the car body crane 2 puts the car body 6 down, the hook on the car body crane 2 is retracted, and the car body crane 2 moves forward again to enter the conveying line. After the lifting mechanism 7 at the end of the line, the lifting mechanism 7 rises and stops when the track of the lifting mechanism 7 is flush with the upper track 4. The car body crane running car s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com