Cotton collecting device of the drafting system of the spinning machine

A drafting device and spinning machine technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of increased manufacturing costs and waste, and achieve the effect of fast and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

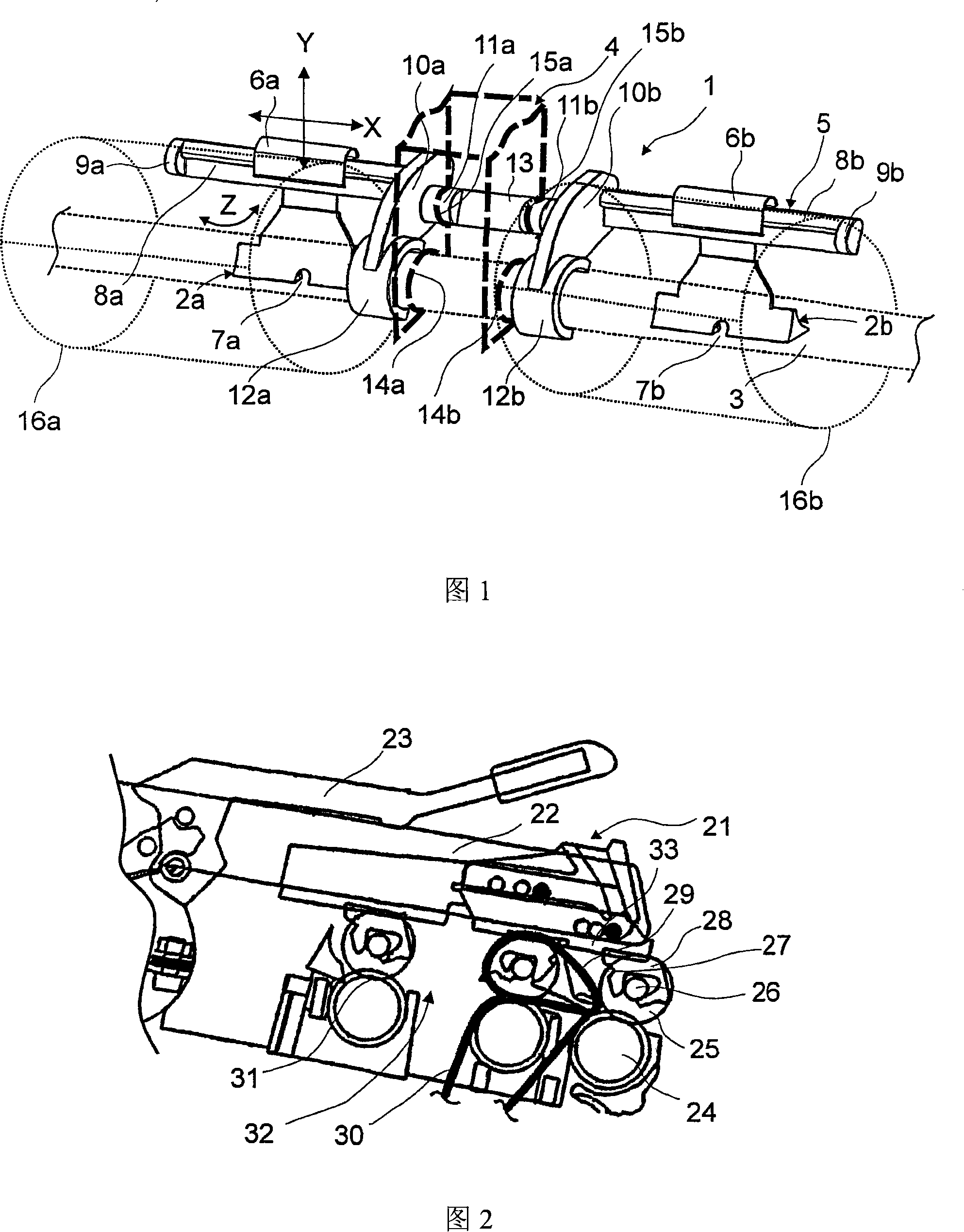

[0054] FIG. 1 shows a cotton collector 1 according to the invention with a support device 5 and two collector elements 2a, 2b for a double drafting device. The supporting device 5 is fastened on the shaft 3 (only schematically shown) of the double top roller 16a, 16b (only schematically shown) by two cylindrical bearing sleeves 12a, 12b respectively arranged on the support arms 10a, 10b, and mounted on the shaft. The two support arms 10 a , 10 b are connected to each other via a web 13 . Guide arms 8a, 8b are connected on both sides of the support arms 10a, 10b, which guide arms extend parallel to the top roller shaft 3, and are movably hooked on each guide arm by a U-shaped bend 6a, 6b There are collector elements 2a, 2b. The collector elements 2a, 2b are mounted such that they are movable or displaceable with a limit in the vertical direction Y, and for example in the horizontal direction X for fiber passage, and can have a limited Rotate around the guide arms 8a, 8b (Z d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com