Oven kang type semi-gasified energy-saving environment-friendly furnace and manufacturing method thereof

An energy-saving and environmentally friendly semi-gasification technology, which is applied in the chemical industry, household stoves/stoves, and the manufacture of combustible gases, etc., can solve the problems of low combustion-supporting efficiency, high pollution, and affecting gas production, so as to improve combustion-supporting efficiency and broaden the scope of application , the effect of increasing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

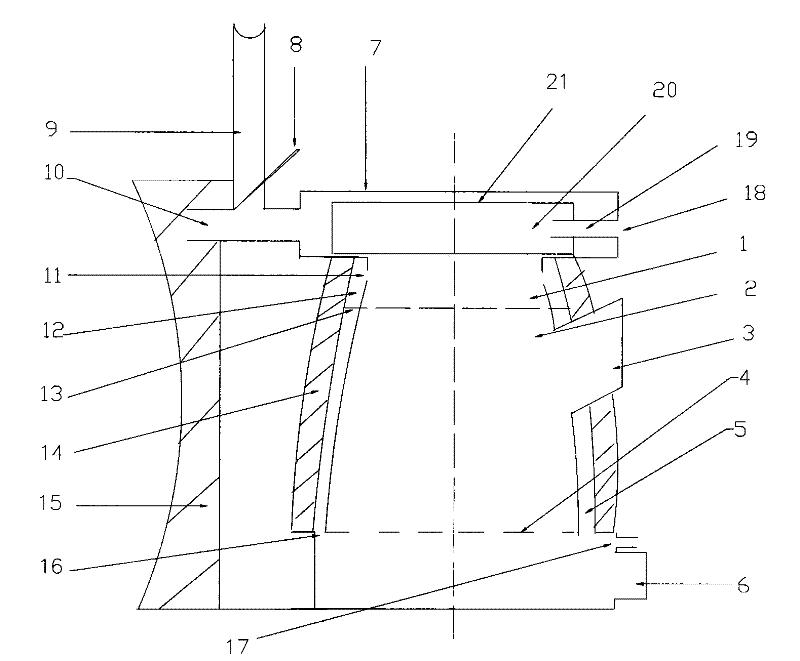

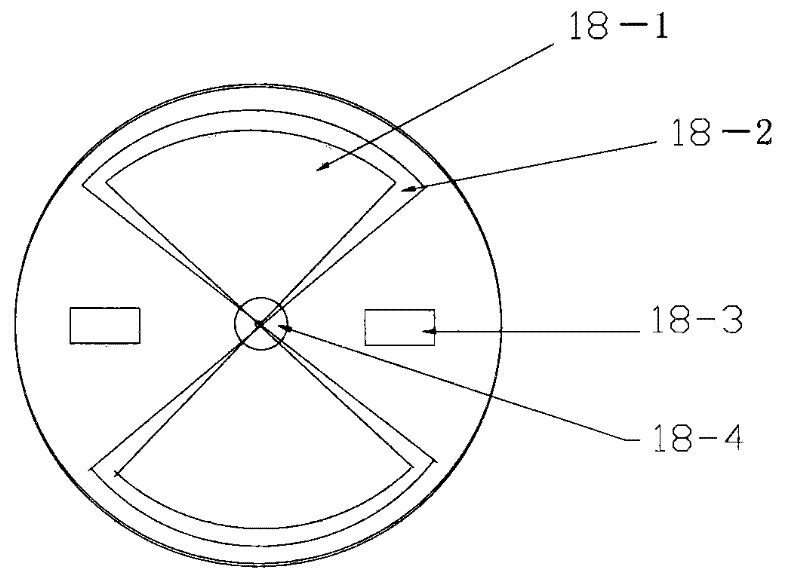

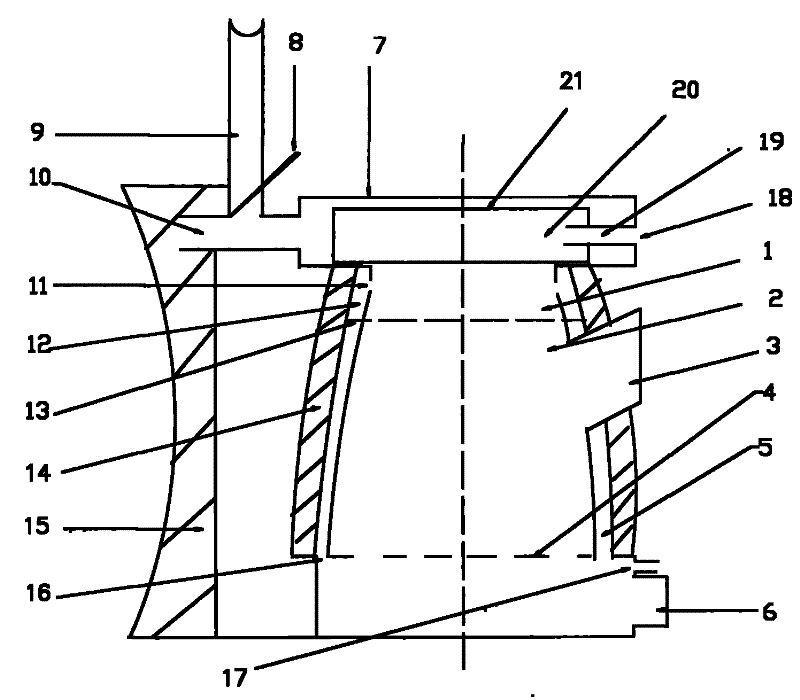

[0036] Such as figure 1 and figure 2As shown, the stove kang type semi-gasification energy-saving and environmental protection furnace of the present invention includes a burner 1, a gasification chamber 2, a feeding port 3, a furnace bridge 4, a secondary air inlet channel or a surrounding space 5, and ash receiving and ventilation chamber 6 , thermal insulation layer 14, panel surrounding fire cover 7, flue changeover switch 8, direct external exhaust flue 9, pit entry flue 10, blower port 17, tertiary air inlet 18, fire ring 21. Biomass fuel is added to the inner chamber of the furnace through the feeding port 3 to control overfilling, avoiding the phenomenon of only smoking but not igniting, and the door can be opened to distribute air when necessary. The air required for combustion is supplied through the ash receiving and ventilating chamber 6 and the furnace bridge 4, and the air supply is controlled by adjusting the opening of the ash receiving and ventilating chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com