A complete set of buried garbage compression equipment

A technology of garbage compression and complete sets of equipment, which is applied in the direction of garbage cans, garbage transmission, garbage collection, etc., and can solve the problems of increasing the garbage processing process of garbage transfer stations, reducing the use efficiency of compression mechanisms, and reducing the capacity of garbage compression, etc., to improve garbage treatment. capacity, improve reliability, and reduce secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

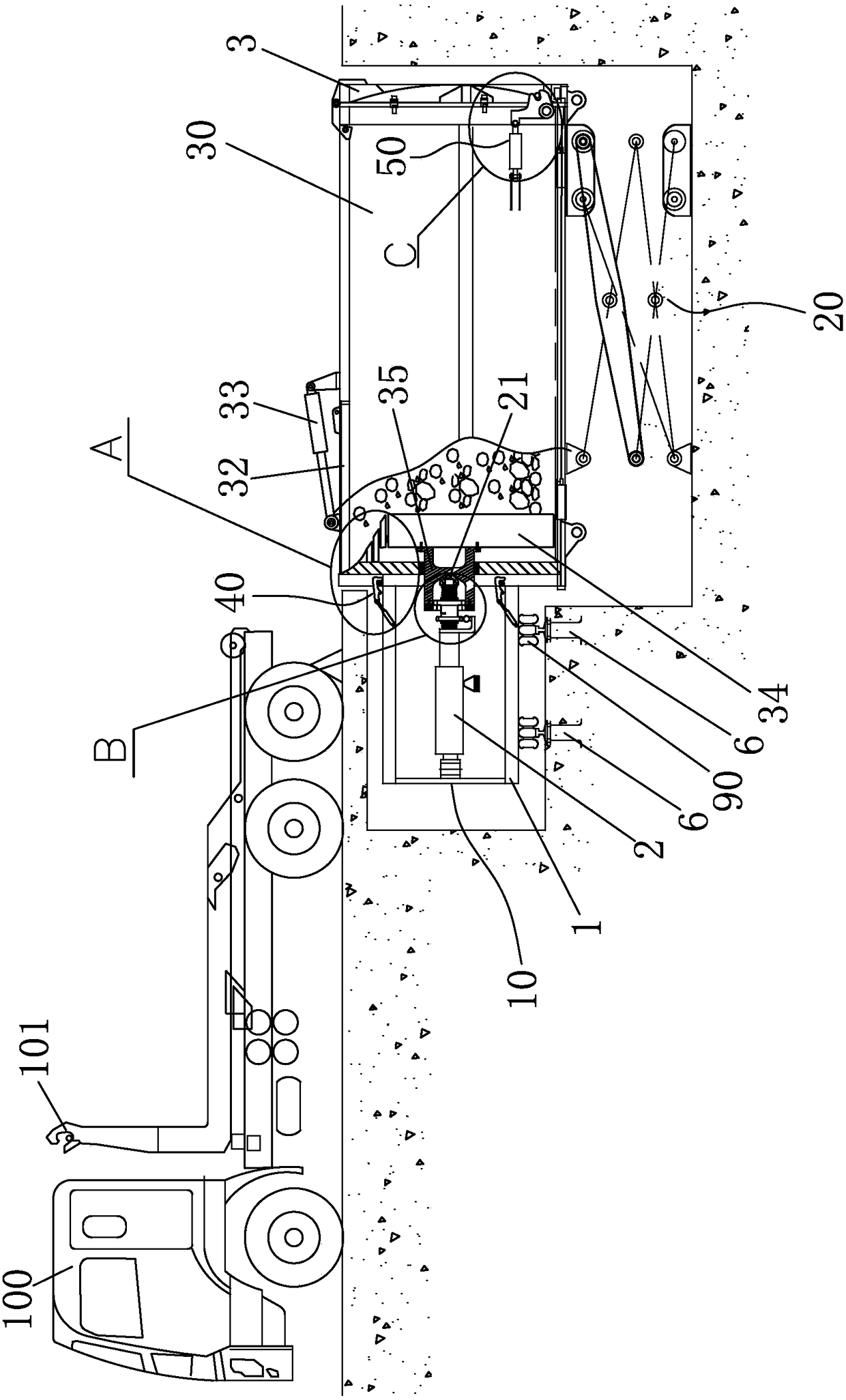

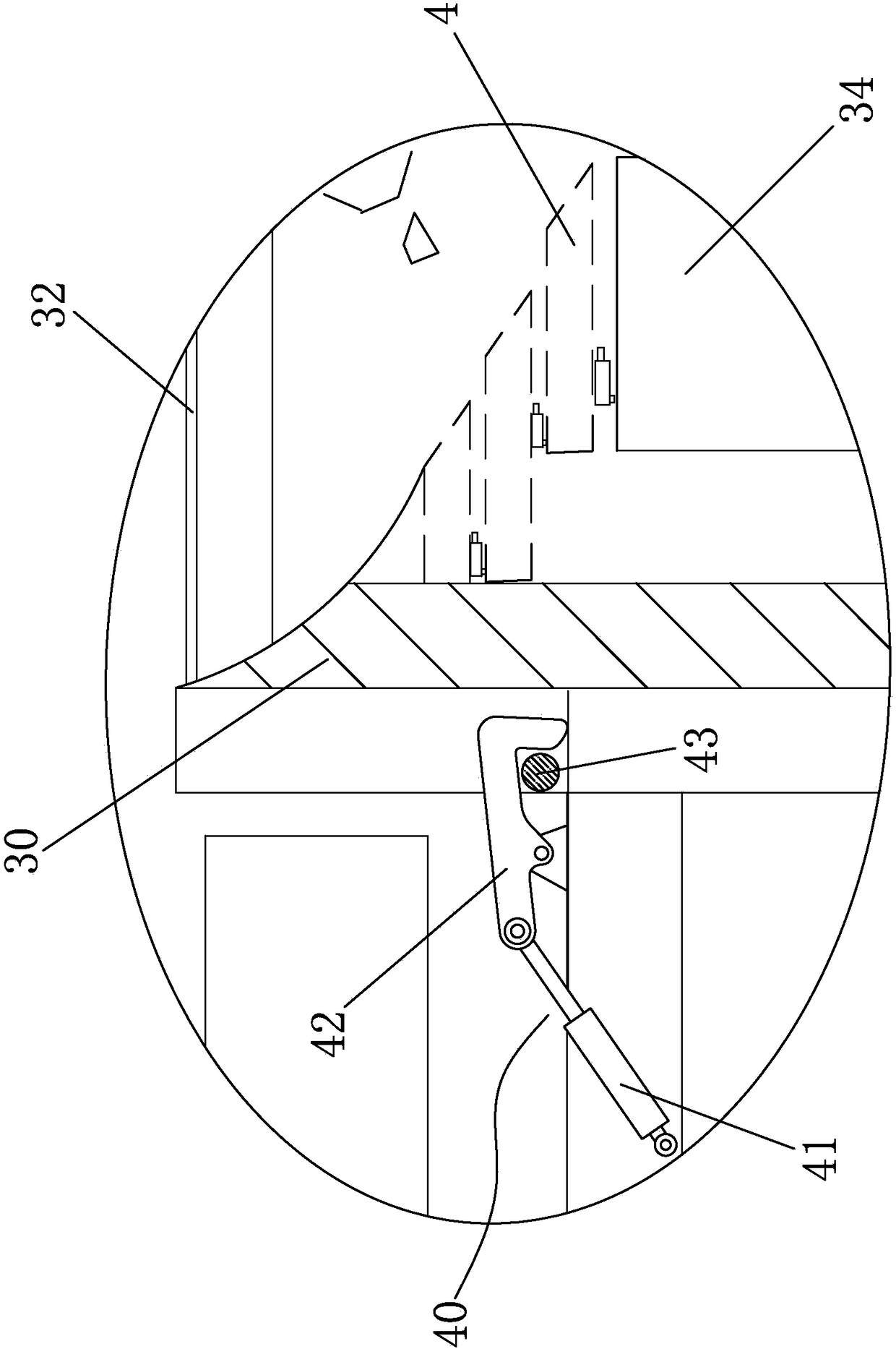

[0029] Figure 1 to Figure 8 As shown, a complete set of buried garbage compression equipment includes a compressor 10 arranged in the pit, a lifting mechanism 20 and a garbage bin 30 supported on the lifting mechanism 20, and the garbage bin 30 is connected with the compressor 10 and the lifting mechanism. The mechanism 20 is a detachable structure, and the dustbin 30 and the compressor 10 are mutually tightened through multiple sets of casing docking locking mechanisms 40 .

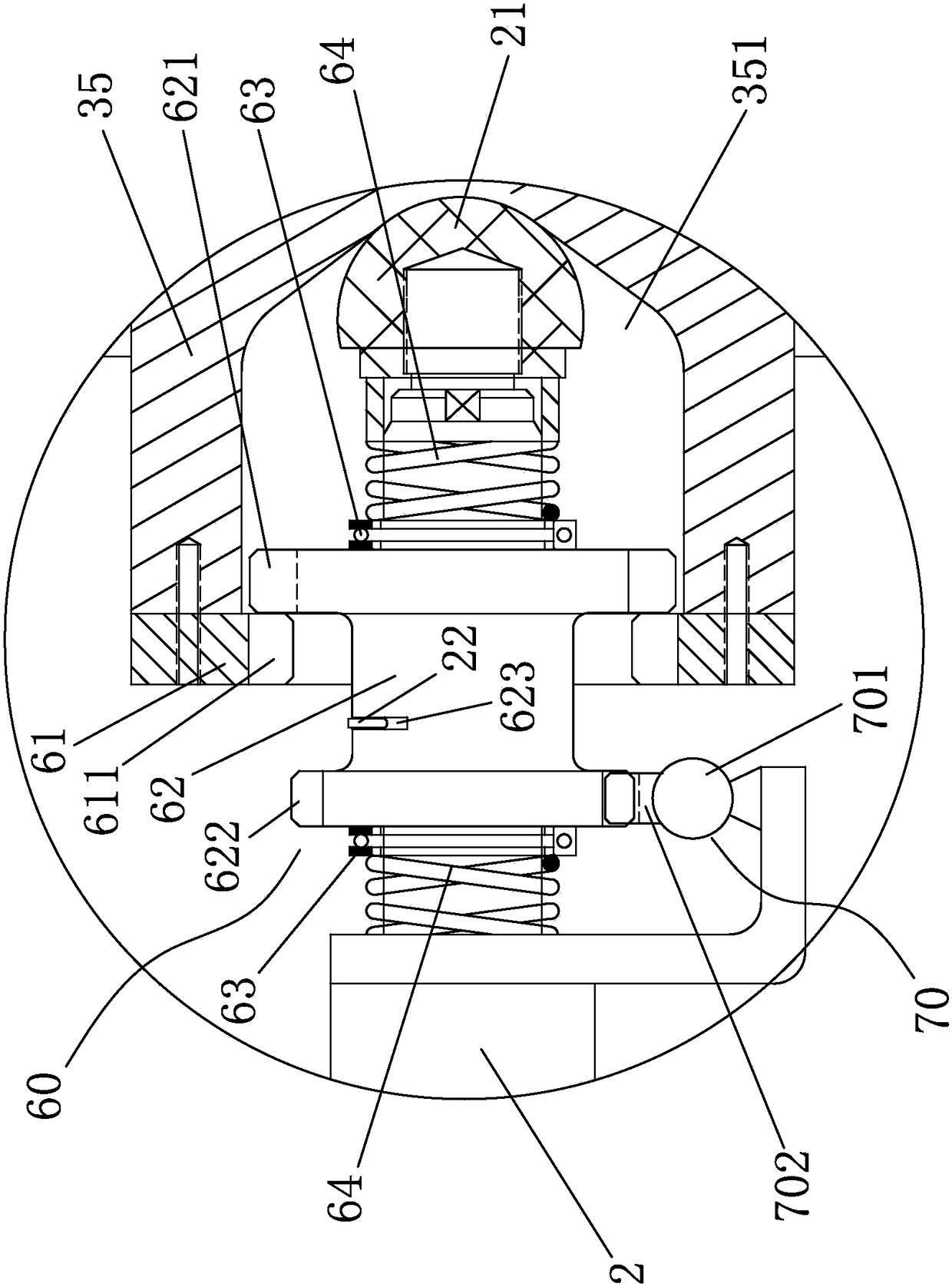

[0030] The compressor 10 includes a frame 1 and two parallel compression oil cylinders 2 mounted on the frame 1, the ends of the piston rods of the two compression oil cylinders 2 are equipped with push heads 21, and the push heads 21 can be fixedly connected by locking At the end of the piston rod of the compression cylinder 2, the outer peripheral surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com