Thread holding device of sewing machine

A technology for holding devices and sewing machines, which is applied in the direction of thread hooks for sewing machines, sewing machine components, sewing equipment, etc. It can solve problems such as not being able to adapt to large-scale production, and achieve the effect of effectively stabilizing the line and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

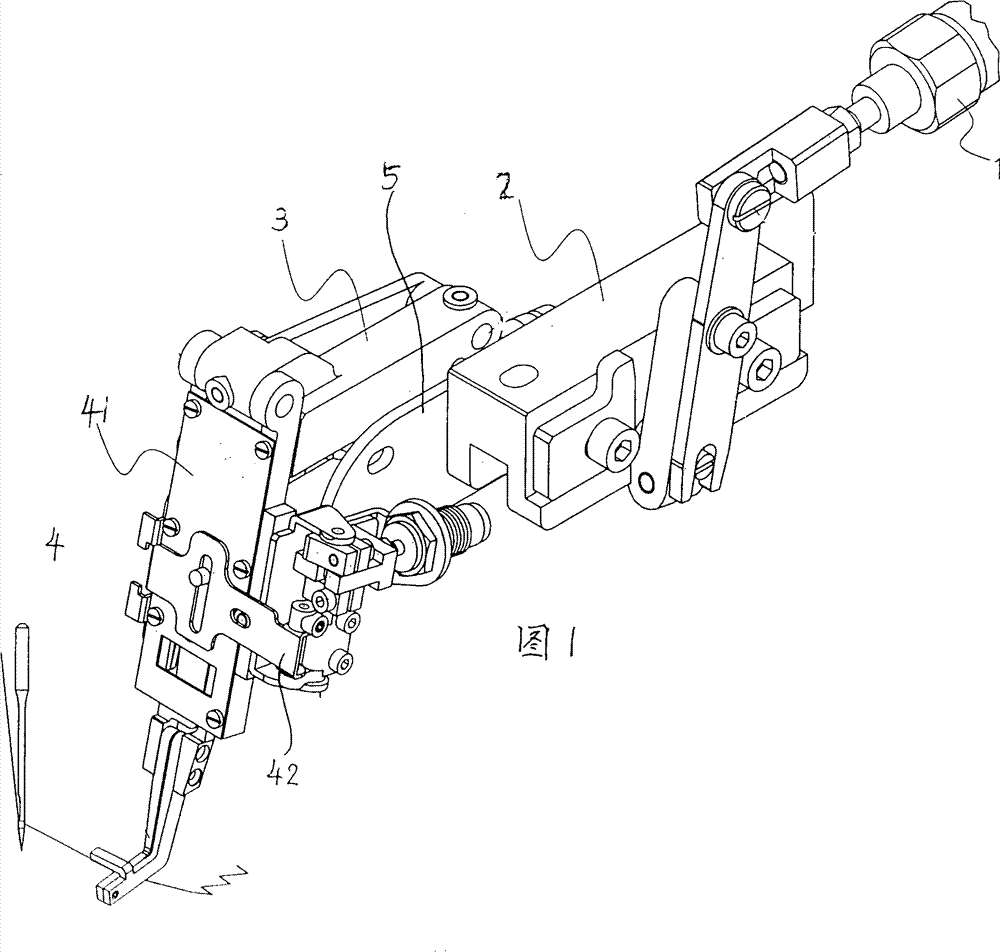

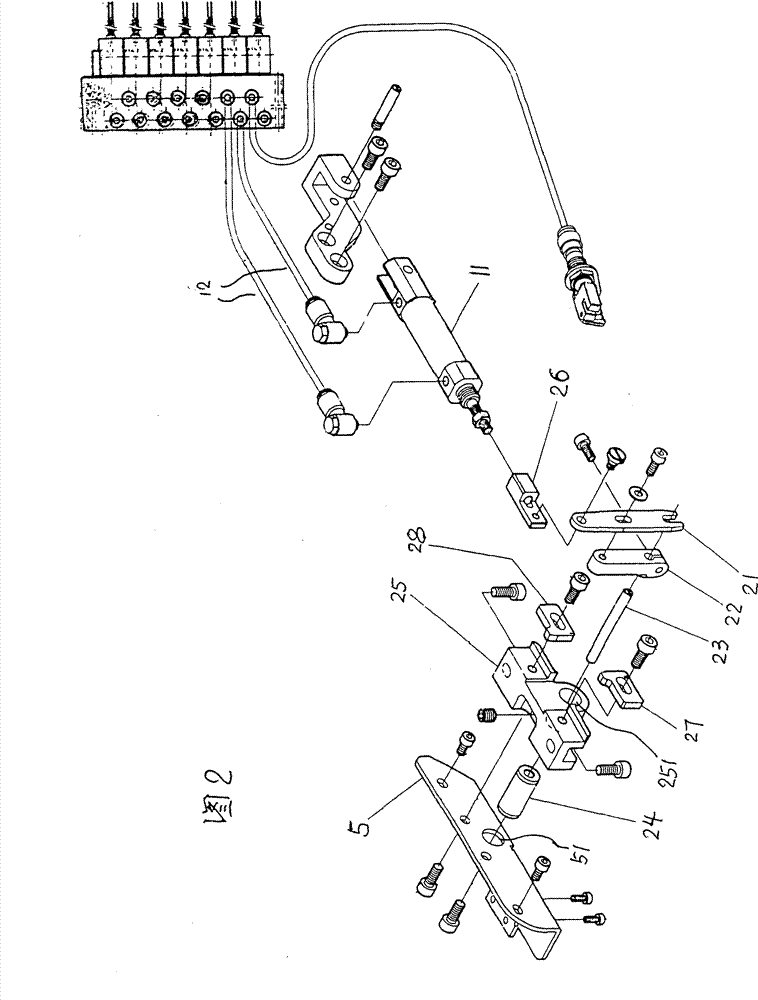

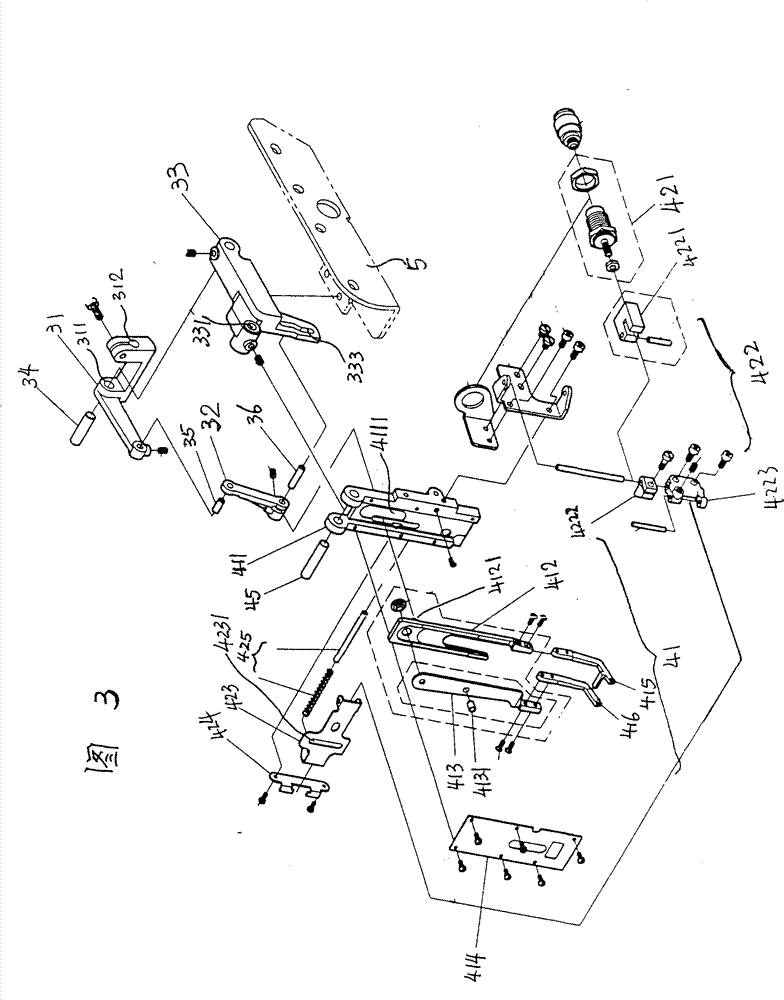

[0022] Please refer to Figure 1, which is a three-dimensional schematic diagram of the present invention. As shown in the figure, the upper thread holding device 10 of the sewing machine is configured to be set in a sewing machine (not shown in this figure), which is mainly composed of a power source 1 , The transmission mechanism 2, the linkage mechanism 3, the wire buckling mechanism 4 and the fixing frame 5. The power source 1 is pivotally connected to the transmission mechanism 2, the transmission mechanism 2 is pivotally connected to the linkage mechanism 3, and the linkage mechanism 3 is pivotally connected to the buckle mechanism 4. The fixing frame 5 is used to fix the device on the sewing machine. Each mechanism uses a pivot to achieve mutual linkage between each mechanism.

[0023] The power source 1 is composed of a pneumatic cylinder 11 and a pneumatic source 12.

[0024] The transmission mechanism 2 is composed of a driving arm 21, a driving arm seat 22, a pin 23, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com