Stepped labyrinth seal decompressing ring for filling compressor

A technology of labyrinth seals and decompression rings, which is applied to engine seals, mechanical equipment, engine components, etc., can solve the problems of short service life of packing and insufficient protection of high-pressure packing sealing rings, etc. , to reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

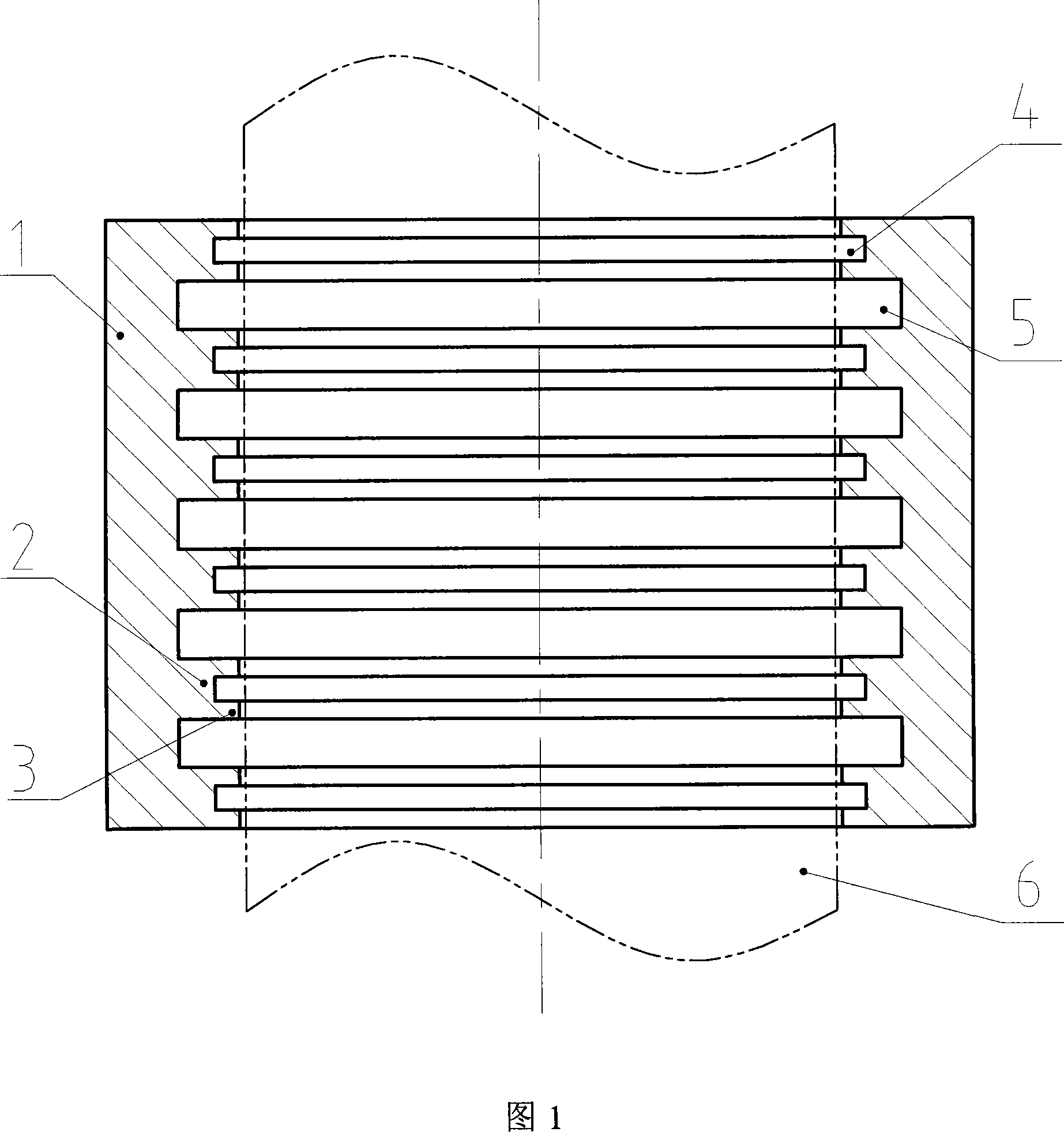

[0015] The present invention is mainly composed of decompression ring 1, high teeth 2, low teeth 3, auxiliary sealing chamber 4 and main sealing chamber 5.

[0016] As shown in Fig. 1 : a plurality of high teeth 2 are arranged on the inner ring of the decompression ring 1, and a main sealing chamber 5 is formed between two adjacent high teeth 2, and the main sealing chamber 5 adopts a labyrinth sealing structure. Two low teeth 3 are arranged on the high teeth 2 , and a secondary sealed chamber 4 is formed between the two low teeth 3 . The secondary sealing chamber 4 adopts a labyrinth sealing structure. The high-pressure gas passes through the gap between the lower teeth 3 of the inner ring of the decompression ring 1 and the surface of the piston rod 6, and then flows from the high-pressure side of the decompression ring 1 to the low pressure side. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com