Liquid, electric rectilinear movement executor

A linear motion, actuator technology, applied in fluid pressure actuation devices, non-electric variable control, instruments, etc., can solve the problems of high positioning accuracy, difficult to achieve driving power, etc., and achieve the effect of fast output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

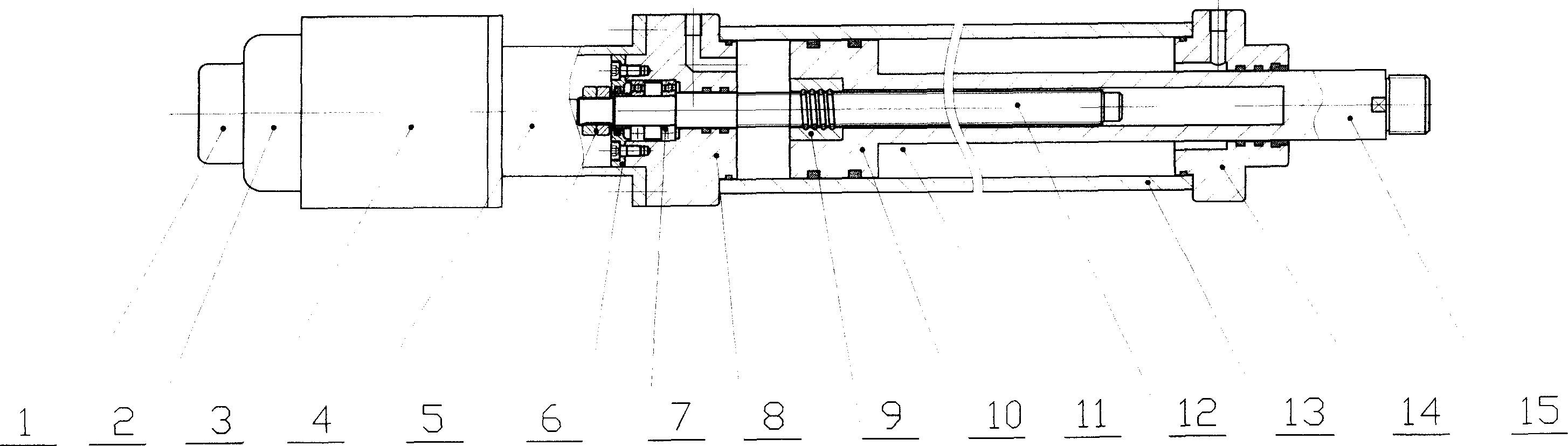

[0018] The present invention fixes the deceleration device 4, the motor 3, the electromagnetic brake 2, and the photoelectric sensor 1 on the rear end 8 of the fluid transmission cylinder, and installs a screw 12 in the rear end cover of the cylinder. The screw 12 is composed of a nut 5 and a bearing 7, and the end The cover 6 is axially fixed and can only rotate but cannot move axially. The motor 3 is connected with the lead screw 12 through the reduction device 4. The nut 9 matched with the lead screw is embedded in the piston 10. When the motor 3 is working, the lead screw 12 rotates. , the nut drives the piston to move, the lead screw is hidden in the hollow piston rod 15, and the piston and piston rod are installed in the cylinder block composed of the end caps 8, 12 and the cylinder barrel. The fluid cylinder outputs thrust and speed, and can play a guiding role. The electric screw 15 and nut 9 also output thrust and control speed, and play the functions of controlling sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com