Trolley frame provided with low ground plate and high ground plate

A low-floor, low-floor technology, applied in the direction of manufacturing tools, wood processing equipment, sawing equipment, etc., can solve the problems of increased labor intensity, excessive manpower manual operation, low degree of automation, etc., to save manpower and financial resources, and device structure Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

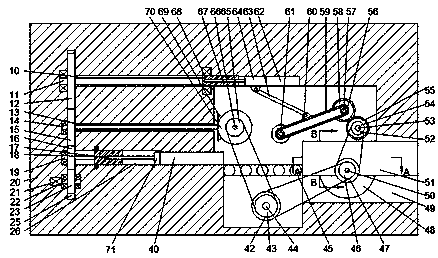

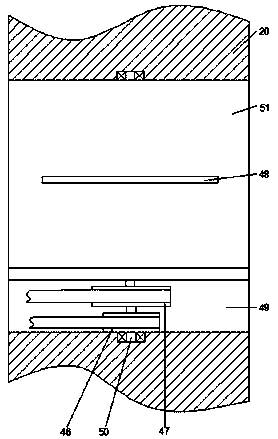

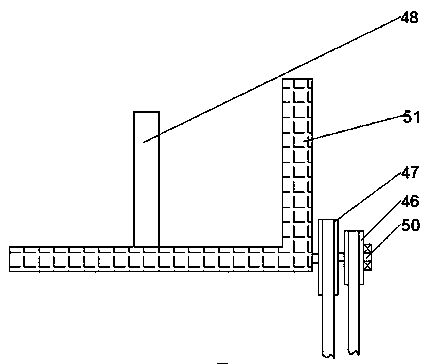

[0018] Such as Figure 1-3 As shown, a vehicle frame with a low floor and a high floor of the present invention includes a frame body 20, a motor 21 is provided inside the frame body 20, and a motor 21 located in the frame body 20 is provided on the right side of the motor 21. The first placement groove 25, the first placement groove 25 is provided with the first rotating rod 22 that is rotatably fitted to the bottom of the left and right end walls, the extension of the left end of the first rotating rod 22 is connected with the power of the motor 21, the first rotating rod 22 The left end of the first rotating rod 22 of a placement groove 25 is fixedly connected with the first tooth sprocket 23, and the right side of the first placement groove 25 is provided with a connected first through cavity 26, and the first through cavity 26 A second rotating rod 19 is rotationally connected to the first placement groove 25 , and the second rotating rod 19 of the first placement groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com