Device especially frictionclutch or arrester and method for preparing the device

A technology for friction clutches and brakes, which is applied in the field of friction clutches or brakes to manufacture such devices. It can solve problems such as adhesion and the influence of the working performance of the device during the run-in operation stage, and achieve the effect of improving the initial friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

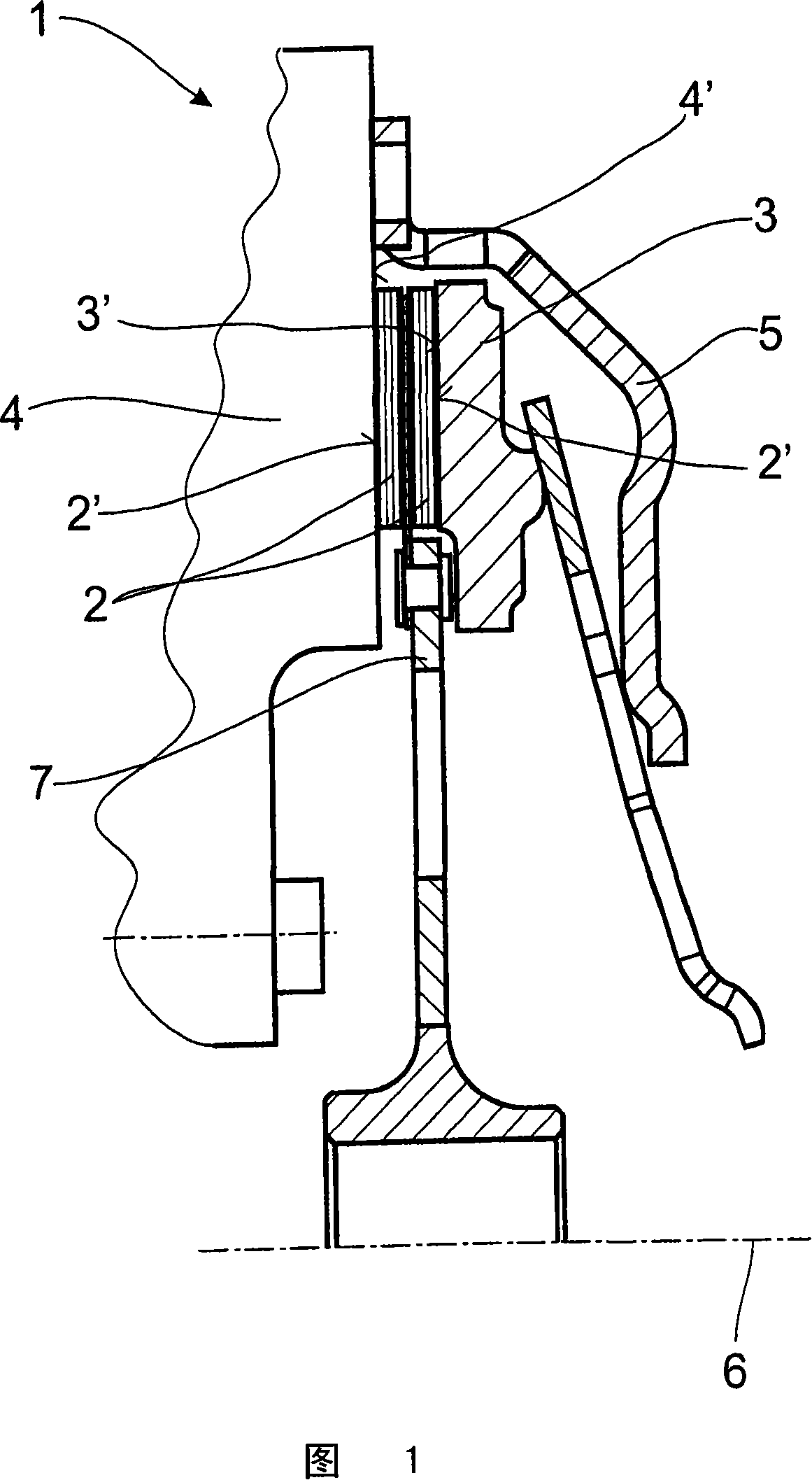

[0021] In FIG. 1 a clutch device 1 can be seen, which is constructed in a conventional manner. The clutch housing 5 is connected in a rotationally fixed manner to the flywheel 4 of the internal combustion engine, the housing 5 together with the flywheel 4 being rotatable about an axis of rotation 6 . Arranged in the housing 5 is a pressure plate 3 , which is mounted in a rotationally fixed manner relative to the housing 5 but is axially slidable. Between the pressure plate 3 and the flywheel 4 is arranged a clutch disk 7 which is provided with a friction lining 2 on each side.

[0022] If the pressure plate 3 is pressed axially in the direction of the flywheel 4, due to the frictional connection between the friction lining 2 and the flywheel 4 or between the friction lining 2 and the pressure plate 3, the torque is transferred from the flywheel 4 to a clutch disc 7 which is non-rotatably connected to a propeller shaft (not shown).

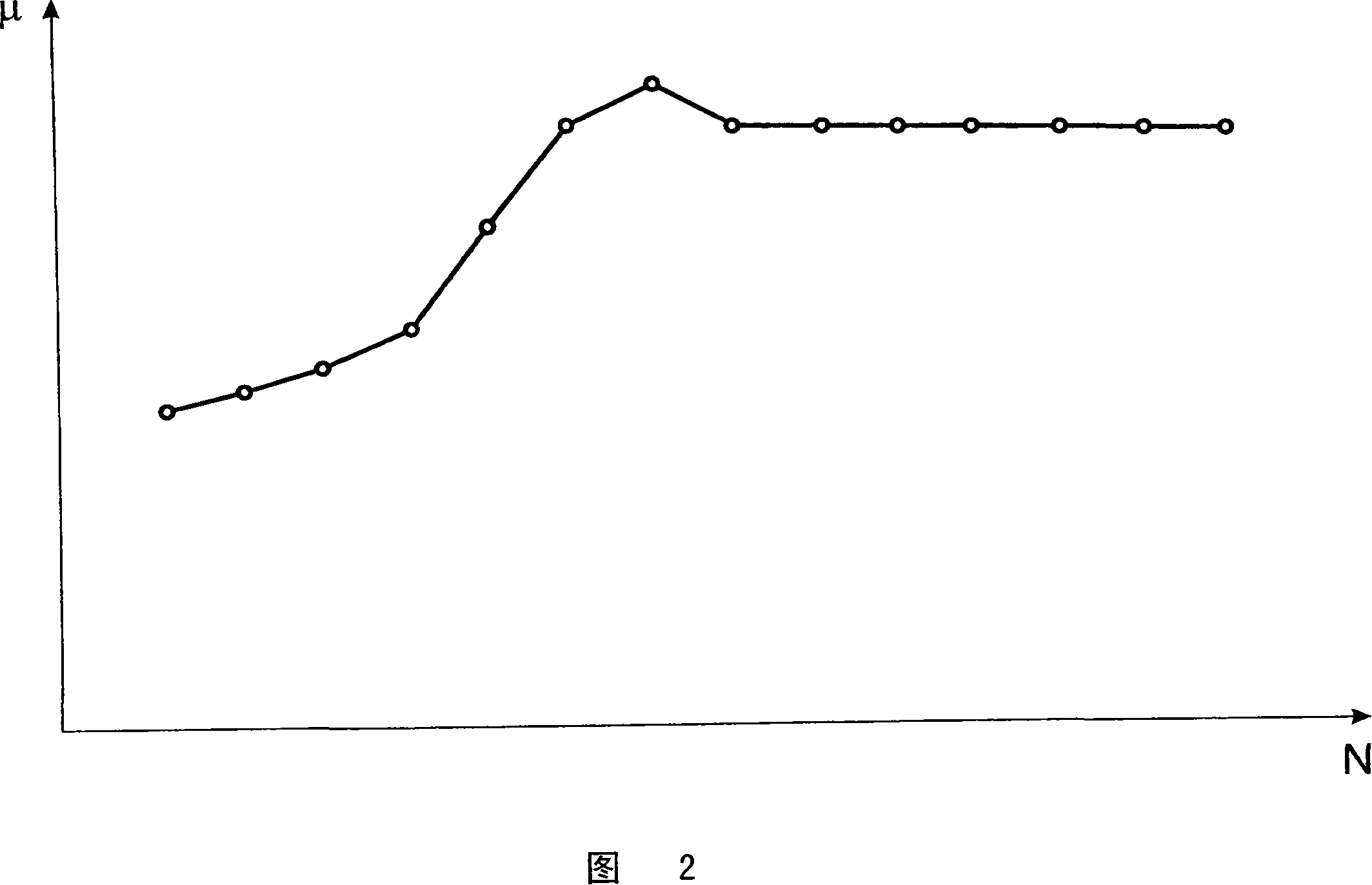

[0023] As can be seen from FIG. 2 , the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com