Friction plate and integrated brake calipers adopting friction plate

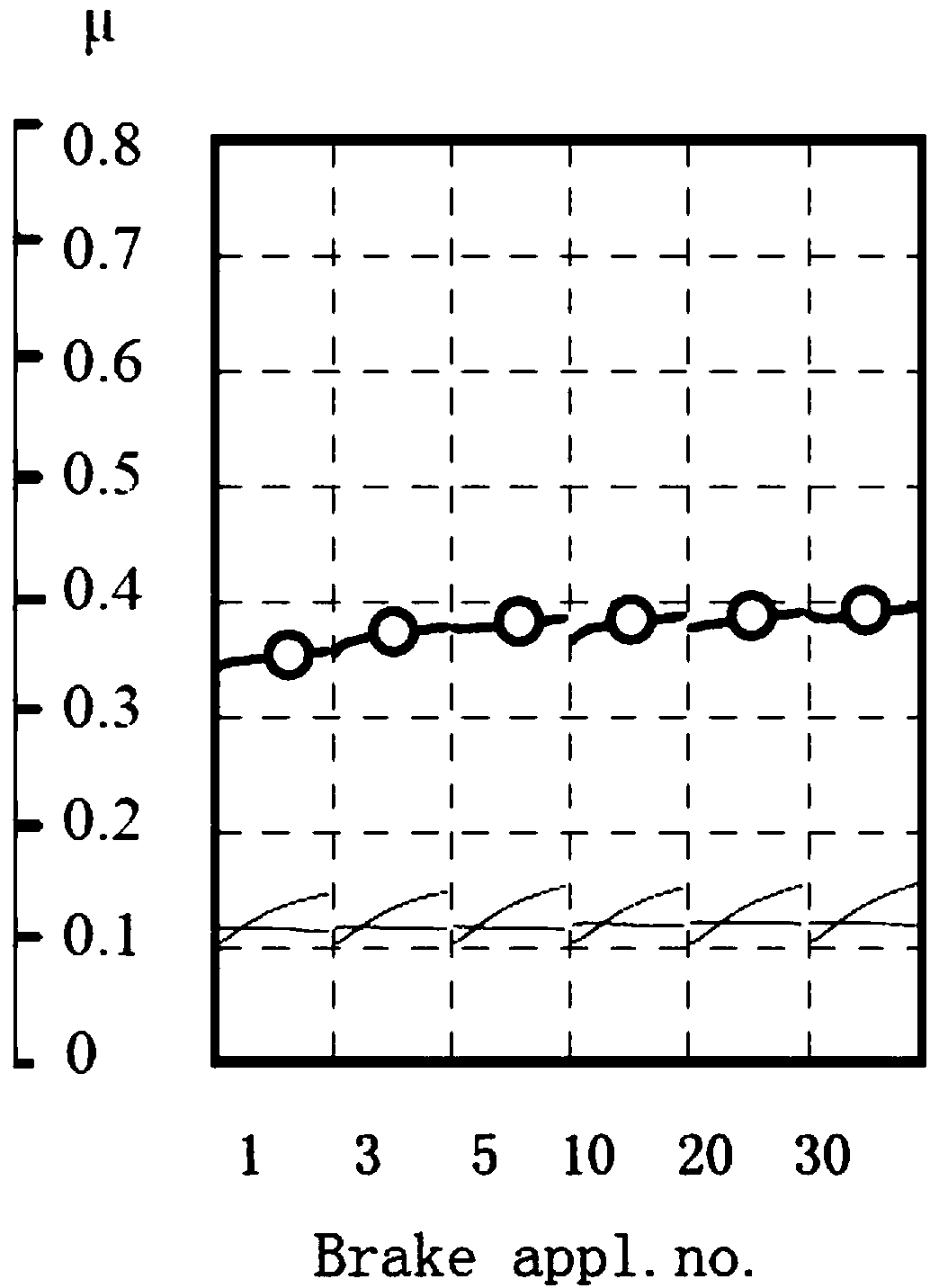

A friction plate and external friction technology, applied in the direction of friction linings, brake types, brake actuators, etc., can solve the problems of unstable parking function of the hand brake, low friction coefficient of friction plates, and brake safety accidents, etc., to achieve friction The coefficient is stable, the cost is low, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach Figure 5 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

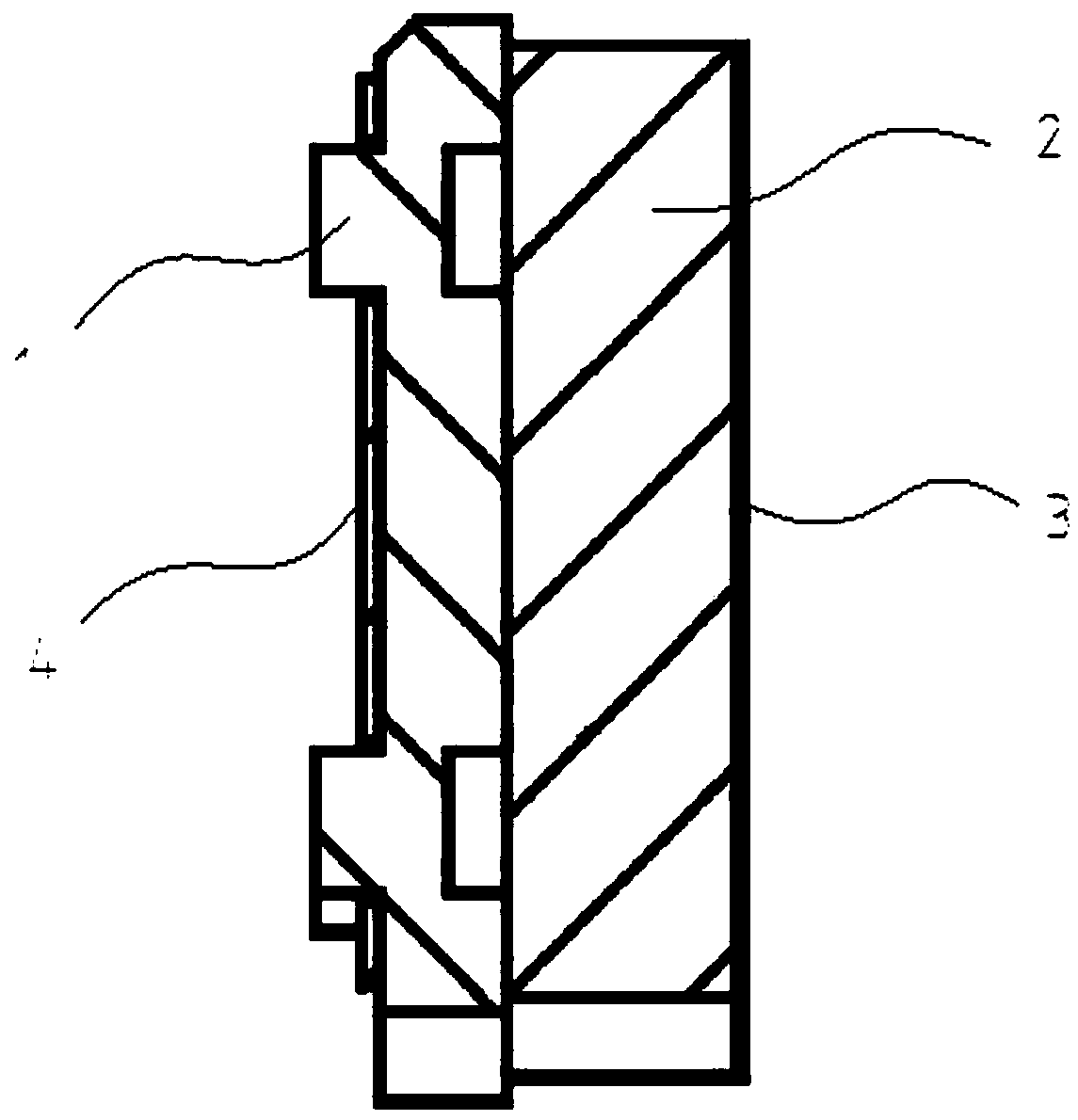

[0023] figure 1 It is a structural diagram of an embodiment of a friction plate of the present invention. like figure 1 As shown, the friction plate of the integrated brake caliper provided in this embodiment includes: a steel back 1 , a friction material 2 , a friction-increasing coating 3 and a sound-absorbing plate 4 .

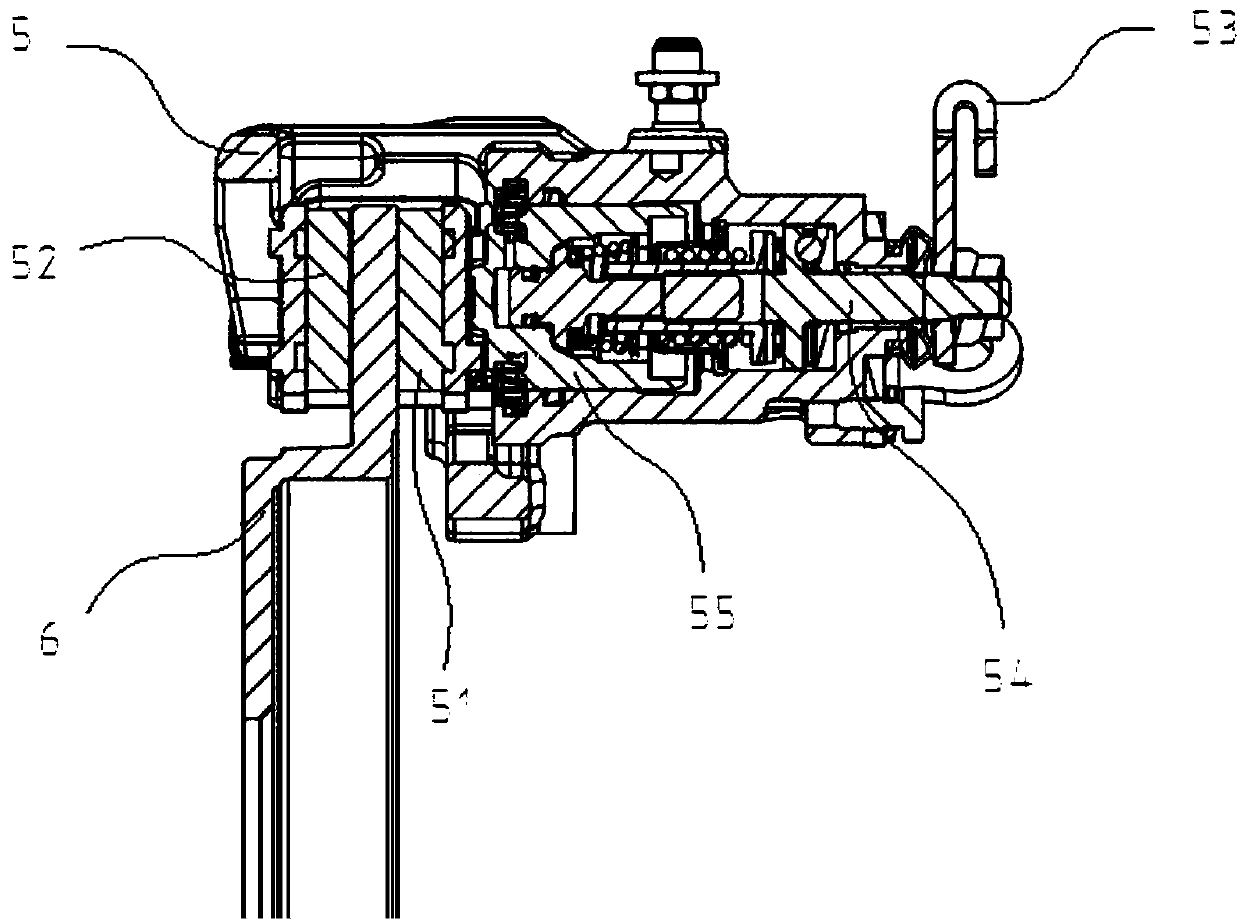

[0024] Specifically, the friction plates of the integrated brake caliper include an inner friction plate 51 and an outer friction plate 52 , wherein the inner friction plate 51 and the outer friction plate 52 are arranged oppositely, and both have the same structure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com