Heavy caliber seamless steel pipe supersonic and vortex combined automatic detection device and uses

An automatic detection device and detection device technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve problems such as the inability to realize the joint automatic detection of large-diameter seamless steel pipes by ultrasonic and eddy current, and achieve the degree of automation and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

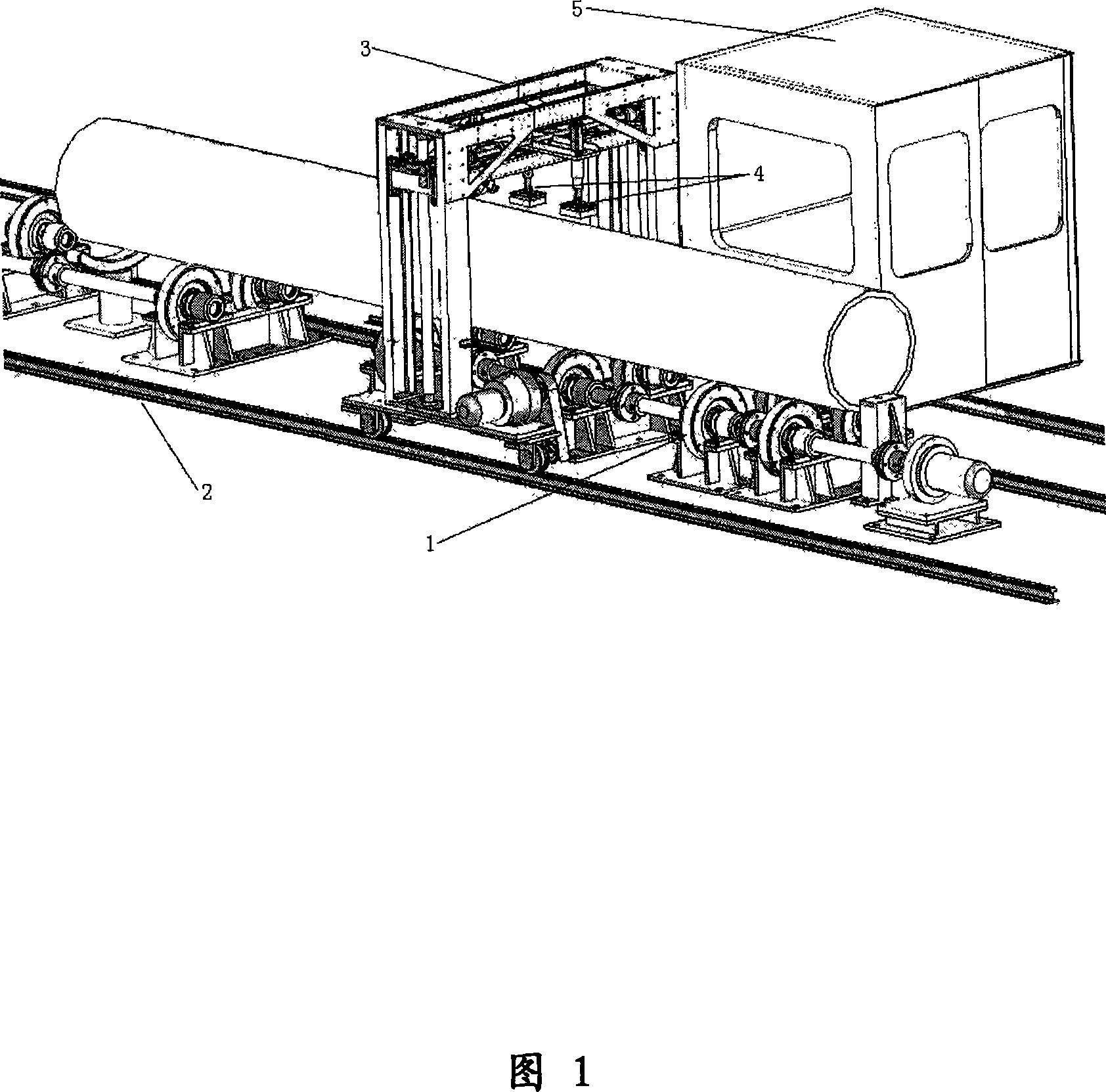

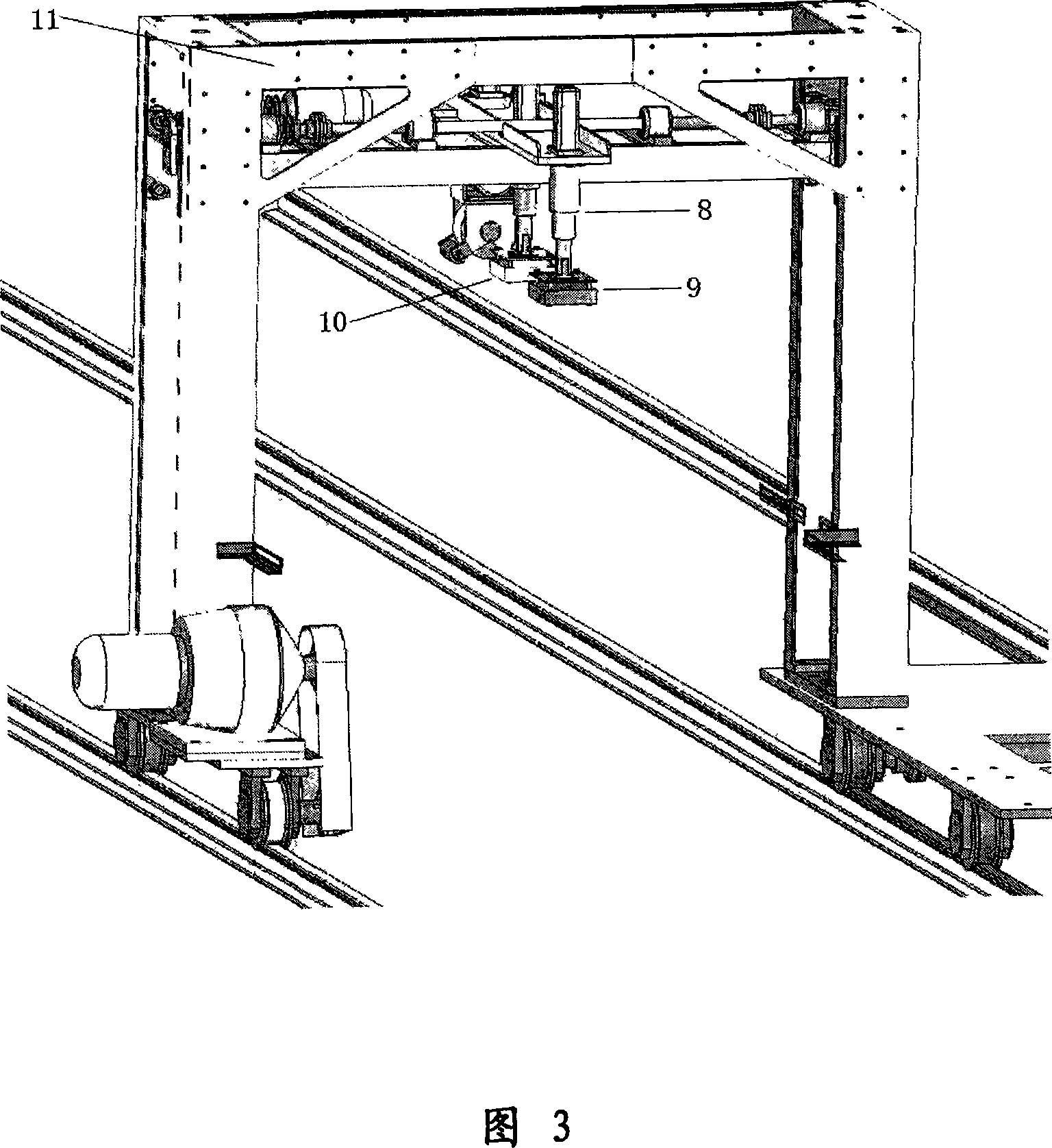

[0030] The large-diameter seamless steel pipe ultrasonic / eddy current combined automatic detection equipment of the present invention consists of a rotating raceway 1, a three-wire track 2, a detection gantry 3, a probe tracking vehicle 4 and a follow-up operation vehicle 5, as shown in Figure 1.

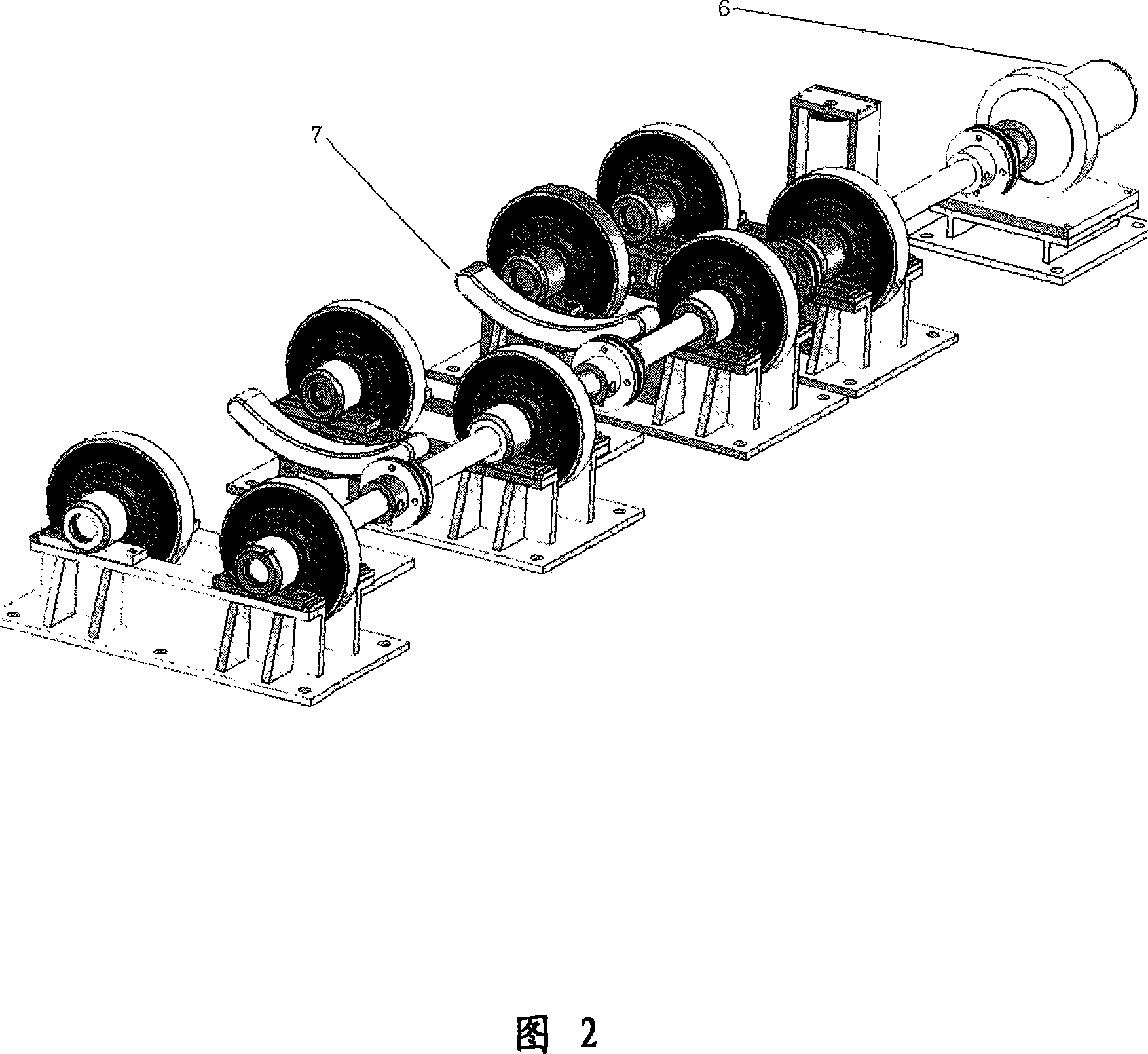

[0031] The rotating raceway 1 is composed of two or three sets of rollers, and the rollers are driven and rotated by the motor 6, as shown in FIG. 2 . When the steel pipe is placed on the raceway, the steel pipe is driven by the roller to rotate in situ. The rotation speed of the steel pipe can be adjusted through the frequency converter according to the steel pipe diameter and flaw detection requirements. The steel pipe is hoisted to the raceway by the crane in the workshop. In order to avoid the impact on the raceway when the steel pipe is hoisted, a jack 7 driven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com