Pressure automatic adjusting device for dive motor

A submersible motor, automatic adjustment technology, applied in the direction of electromechanical devices, pump devices, electric components, etc., can solve the problems of the impact of the life of the submersible motor, the lack of water in the motor cavity, the overflow of water or oil, etc., to achieve simple structure, pressure regulation volume Large, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

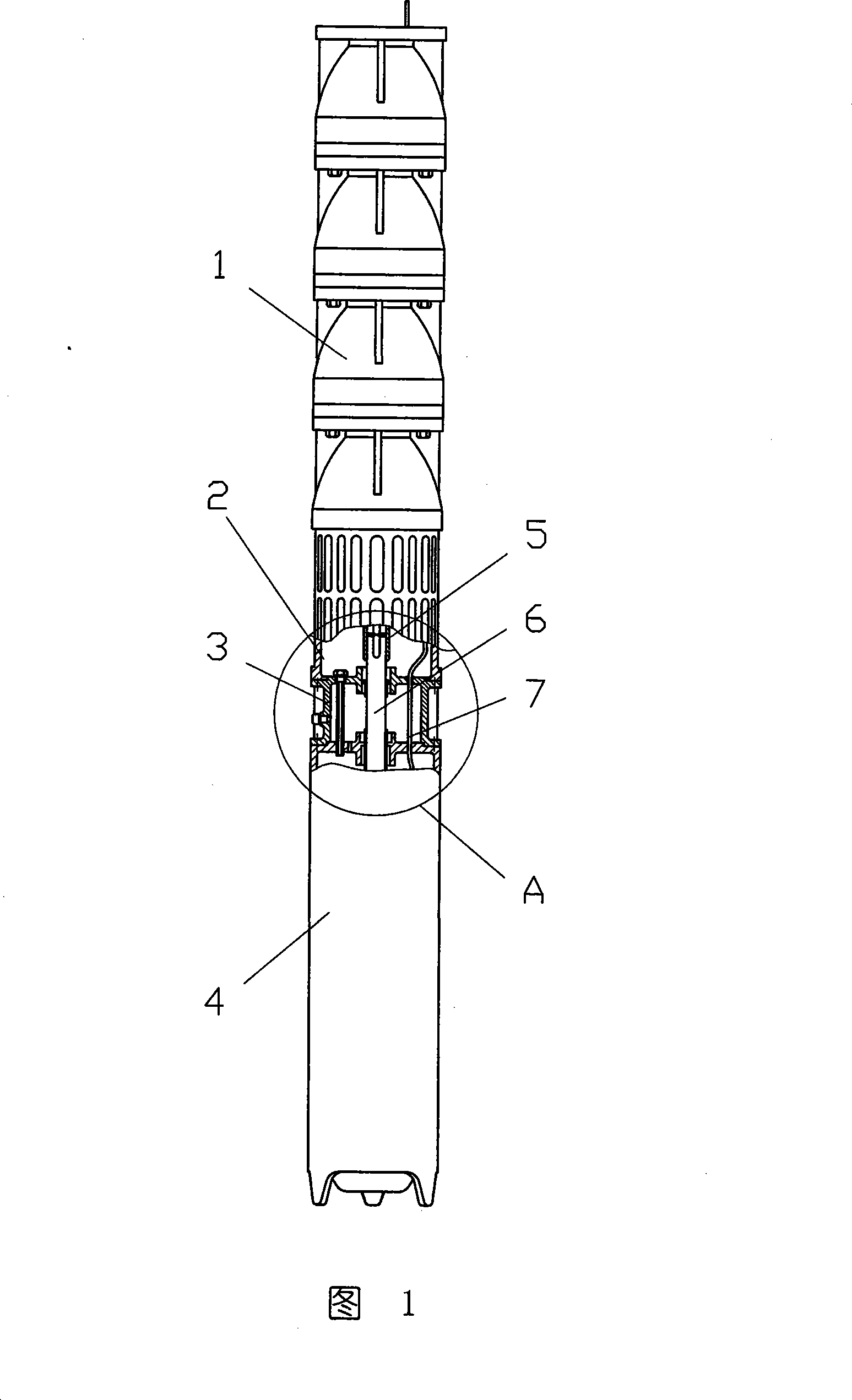

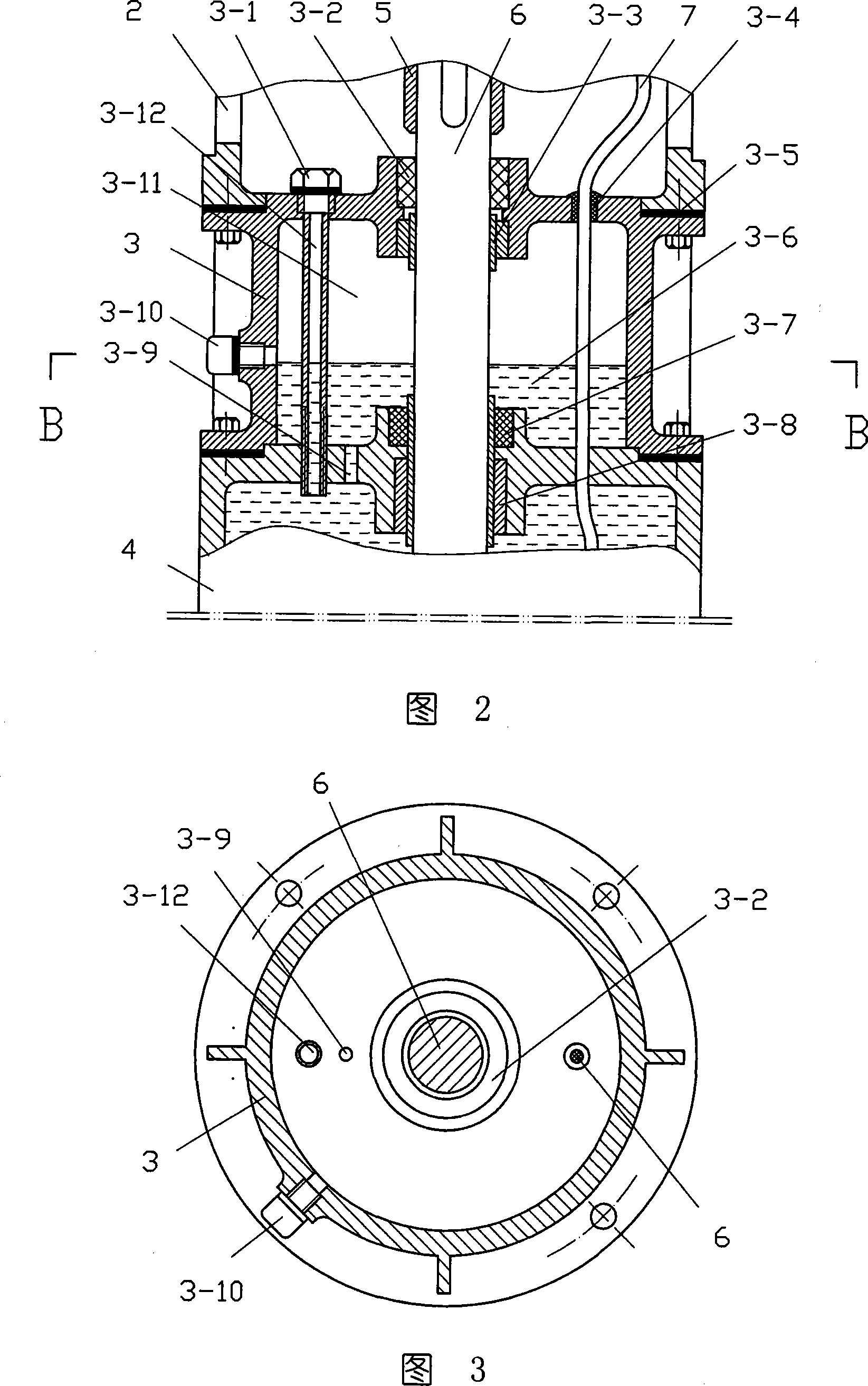

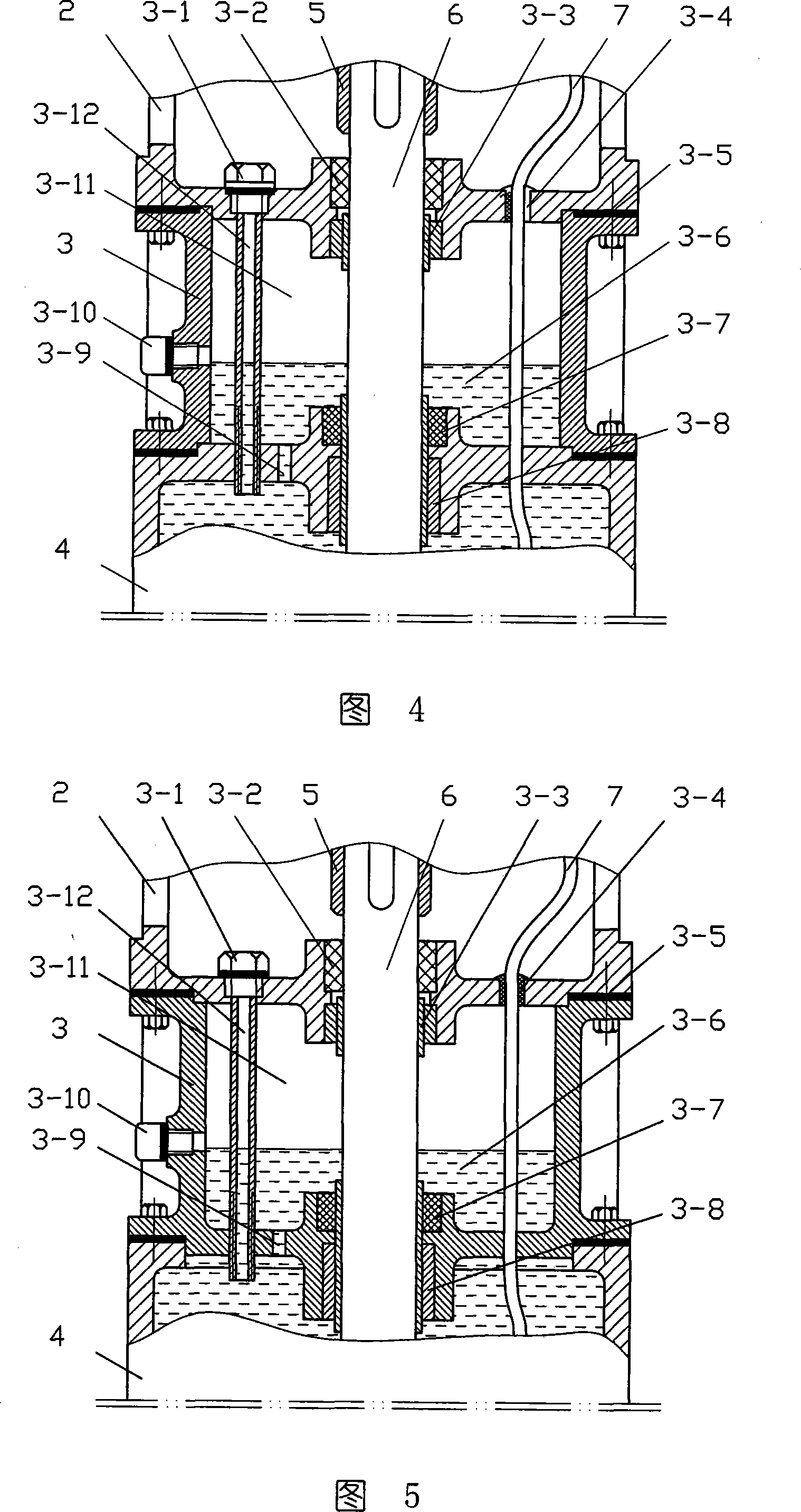

[0025] Shown in Fig. 1-3 is a kind of embodiment of submersible motor pressure automatic adjustment device of the present invention: its basic structure is shown in the figure, and the main innovation point of the present invention is to be provided with automatic pressure adjustment between submersible motor 4 and water pump Cavity 3, pressure automatic adjustment The cavity 3 is connected to the end of the submersible motor and communicates with the diversion hole 3-9 provided in the inner cavity of the submersible motor. The wall of the pressure regulation cavity is also provided with an overflow hole 3-10. Filled with cooling medium water or oil 3-6. In order to effectively suppress the expansion and contraction of the cooling medium during operation in a high-temperature environment, the present invention reserves a cooling medium expansion space 3-11 in the pressure regulating cavity 3 .

[0026] Set the water injection pipe 3-12 in the pressure regulating chamber to dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com