Cam/compression lock plate

A cam, cam-slot technology applied in the field of osteosynthetic plates and systems of bone to address issues of weakened plate structural integrity, improperly positioned screws or holes, and increased overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

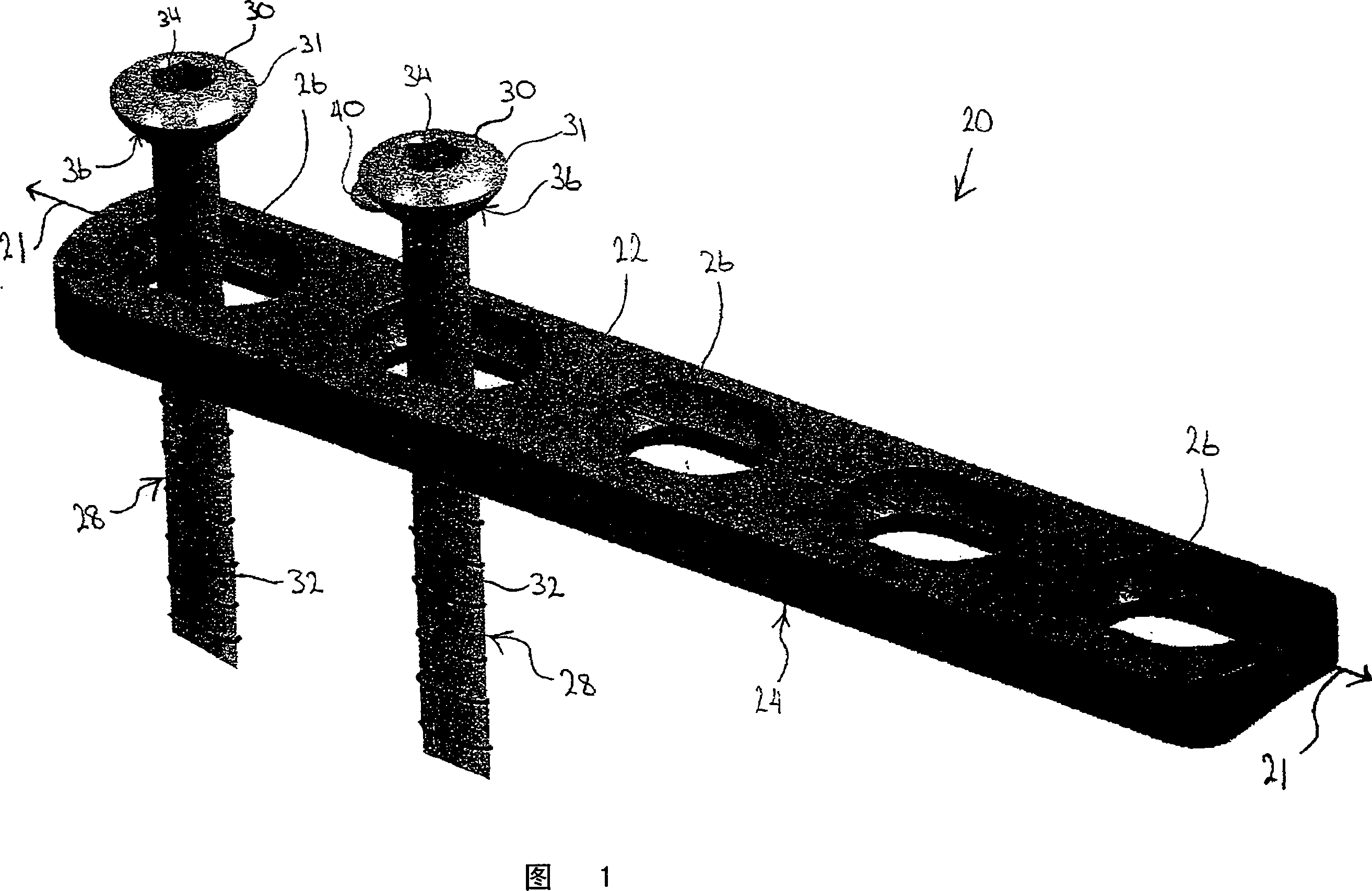

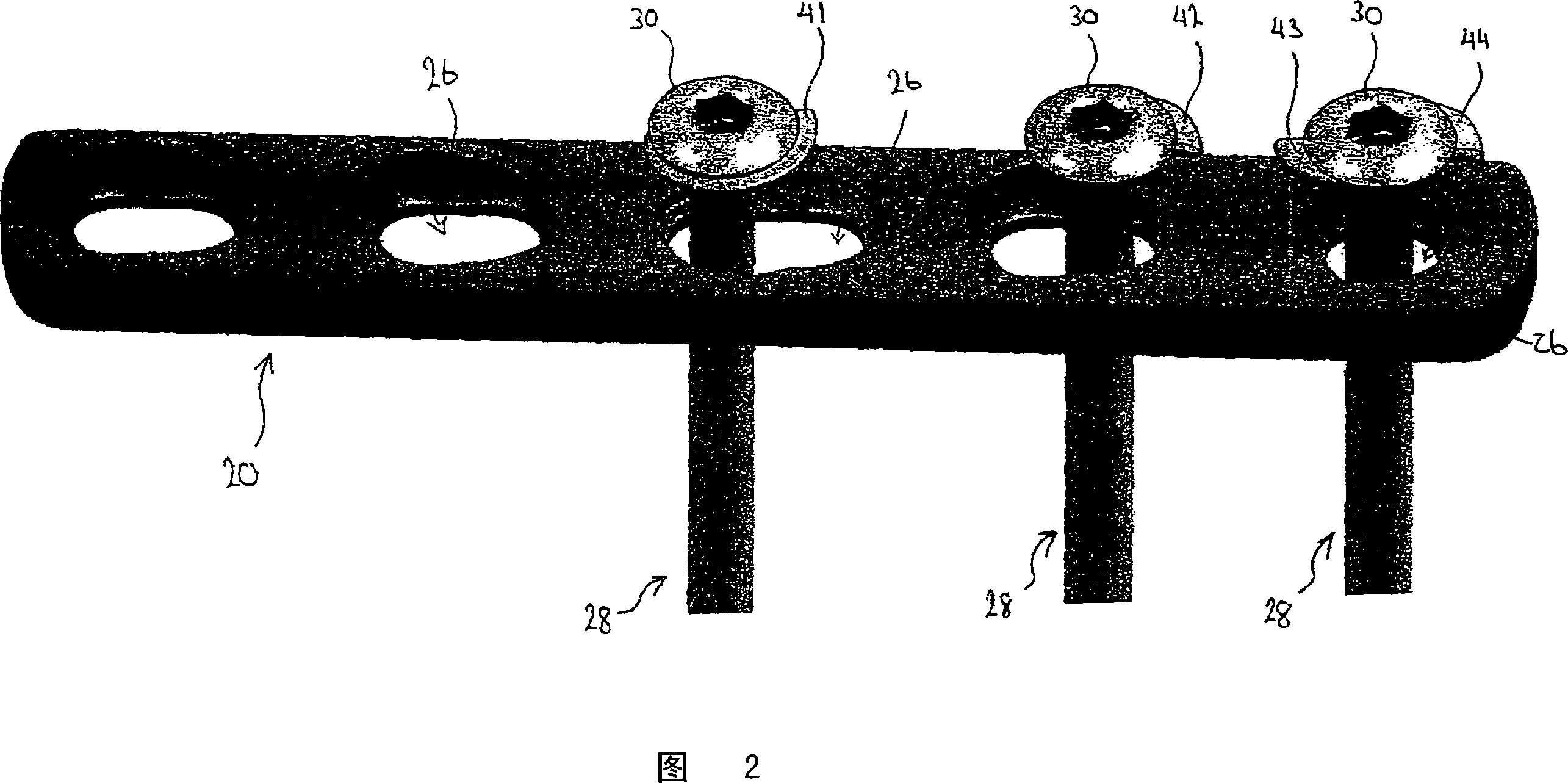

[0028] Referring generally to FIG. 1 , the camming / compression bone plate 20 includes an outwardly facing surface 22 and a bone facing surface 24 opposite the outwardly facing surface 22 . The bone plate may have an elongated shape such that it defines a central longitudinal axis 21 extending the length of the elongated plate. A plurality of holes 26 extend through the bone plate from outward facing surface 22 to bone facing surface 24 . Hole 26 is generally disposed along longitudinal axis 21 , but may be located elsewhere on plate 20 as well. Each of the plurality of holes is configured to receive a bone screw 28 . Both bone plate 20 and bone screw 28 are composed of a biocompatible substance. Examples of such biocompatible substances include: titanium, nickel, cobalt chromium, and other biocompatible substances recognized by those skilled in the art.

[0029] bone screw

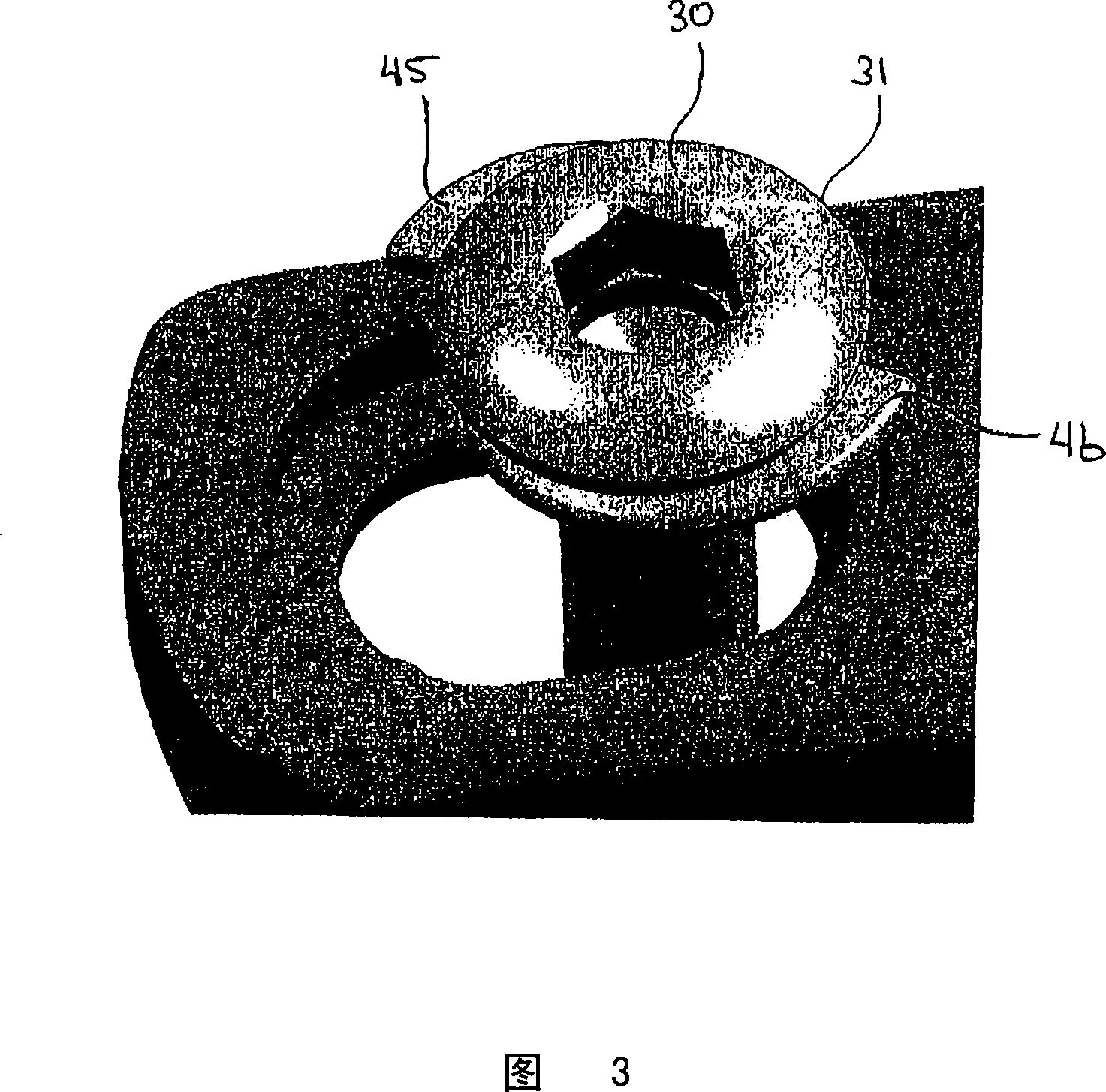

[0030] As shown in FIGS. 1 and 2 , each bone screw 28 generally includes a head 30 having a thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com