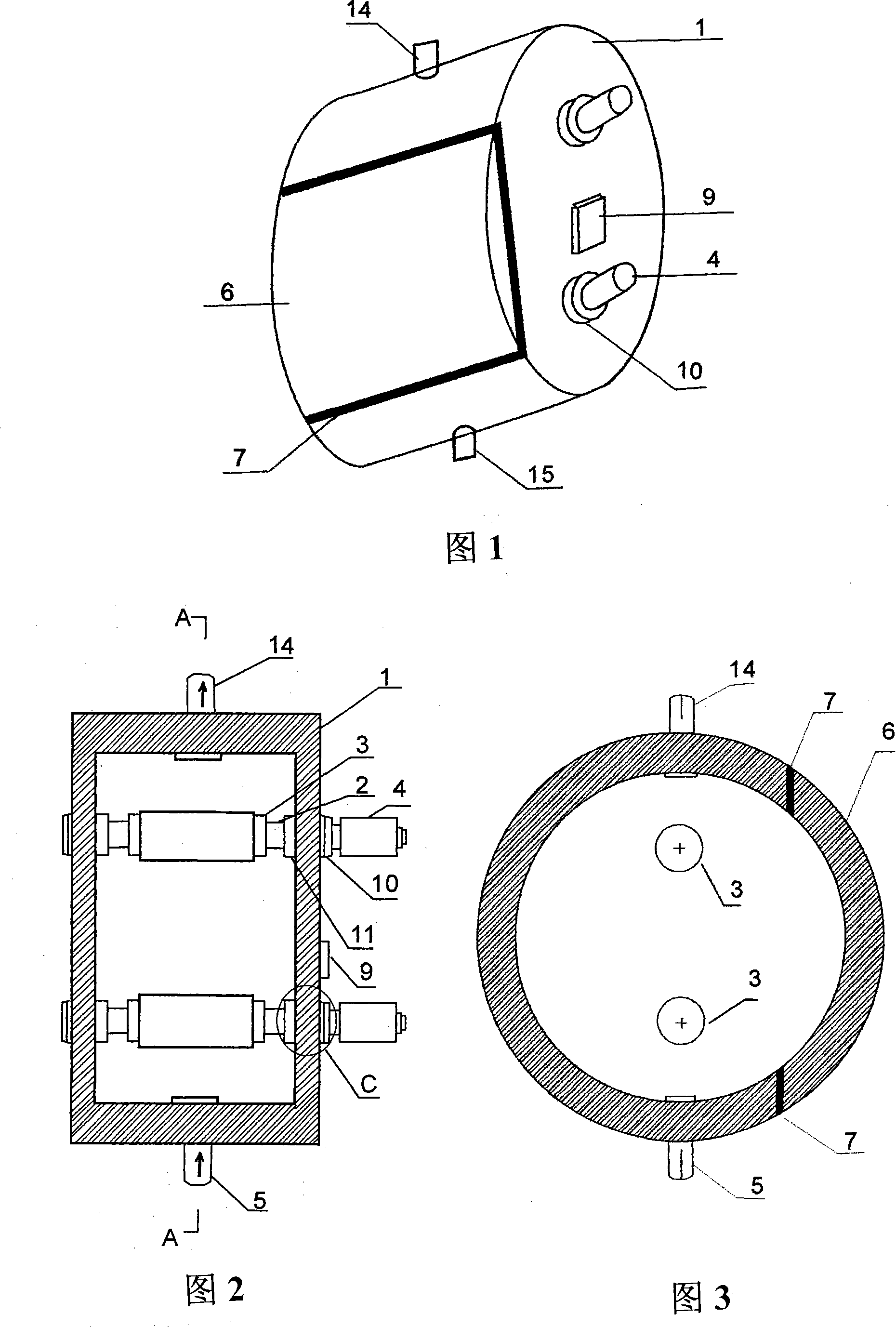

Supercritical dyeing pot

A dyeing tank and supercritical technology, which is applied in dyeing, textiles and papermaking, liquid/gas/steam textile material processing, etc., can solve problems such as uneven dyeing, improve dyeing effect, ensure stability, and avoid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, fabric dyeing:

[0025] 1. Fabric upper shaft: Open the cover 6 of the dyeing tank with a tool, fix the roll 3 on the transmission shaft 2, wind the polyester fabric of a certain width and length onto the roll 3 of a transmission shaft 2;

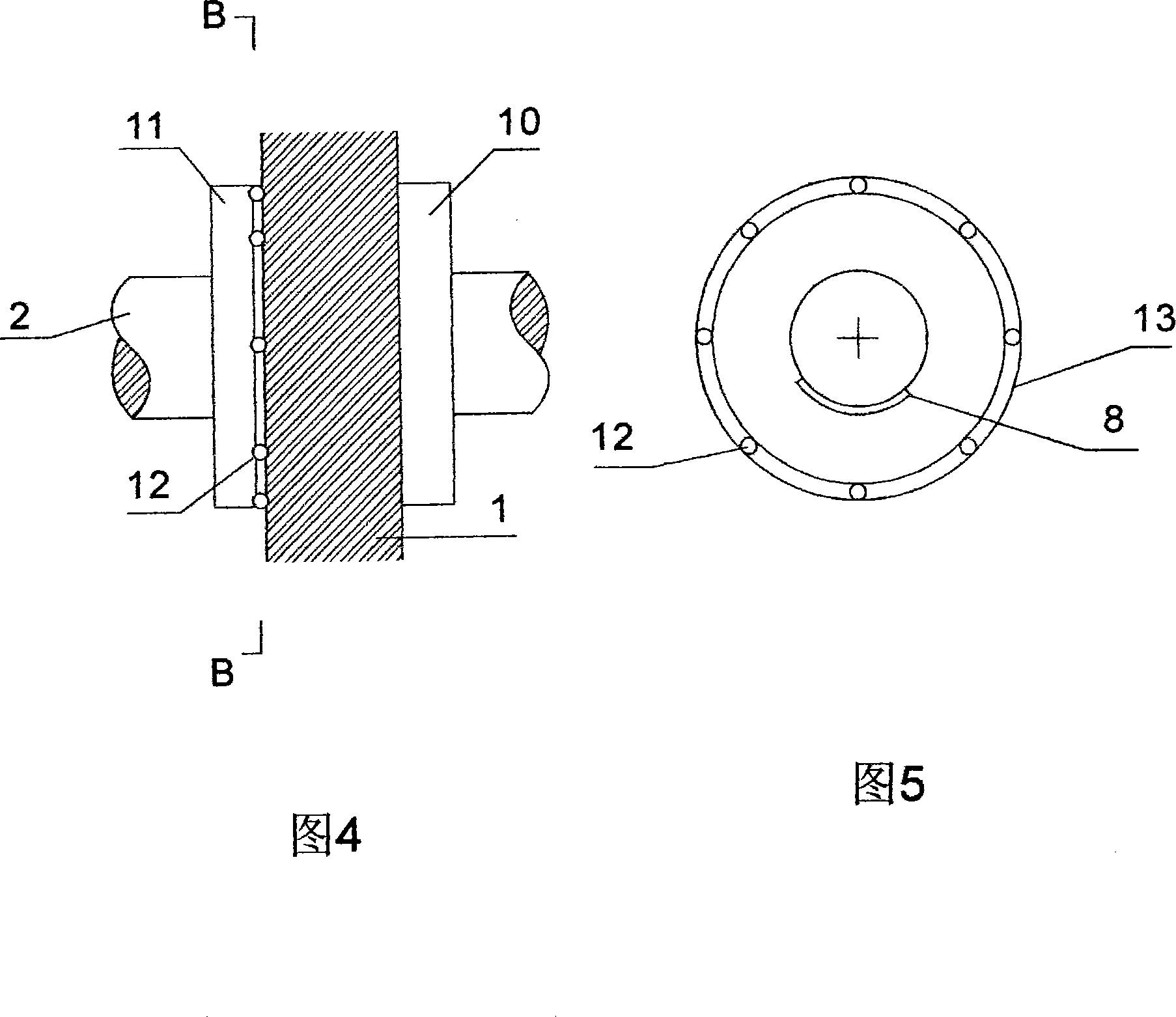

[0026] 2. Transmission shaft fixing: There are two transmission shafts 2, which are respectively fixed. A transmission shaft 2 is fixed at the bushing 8 of the inner wall of the dyeing tank, and there is no roll cloth on the winding roller 3 of the other transmission shaft 2, and this transmission shaft 2 is fixed at another bushing;

[0027] 3. Leading cloth: also known as threading cloth, lead the cloth head on the cloth roll 3 to another empty roll 3 and fix it, the empty roll 3 is active, and the cloth roll 3 is passive;

[0028] 4. Test run: Turn on the external motor 4 and the magnetic coupler 10, the transmission shaft 2 and the winding roller 3 are tightly attracted to the inner wall of the tank body 1 along wi...

Embodiment 2

[0031] Embodiment 2, skein dyeing:

[0032] 1. Skein upper shaft: put a certain amount of polyester blended yarn on the winding roller 3 outside the two drive shafts 2;

[0033] 2. Fixing of the yarn shaft: two winding rollers 3 are respectively fixed at the bushing 8 on the inner wall of the tank body 1, one winding roller 3 is active, and the other winding roller 3 is passive;

[0034] 3. Test run: open the motor 4 and the magnetic coupler 10 outside the tank 1, the transmission shaft 2 is attracted to the inner wall of the tank 1 with the permanent magnet 11, adjust the electromagnetic torque of the magnetic coupler 10, and adjust the metering device 9 to normal status;

[0035] 4. Airtight, enter the supercritical state for dyeing, according to the preset time, manual or automatic rewinding;

[0036] 5. Shaft output: After the dyeing is completed, the dyeing tank can be opened and the shaft can be output when the pressure is released and the temperature is lowered to nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com