A kind of homochromatic dyeing process of viscose fiber fabric containing chitin

A technology for chitin viscose and fiber fabric, applied in the field of dyeing, can solve the problems of difficult to make up for color pattern and uneven dyeing, difficult dye migration and diffusion of dyes, etc., avoiding high-degree adsorption, remarkable adsorption effect, The effect of simple dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

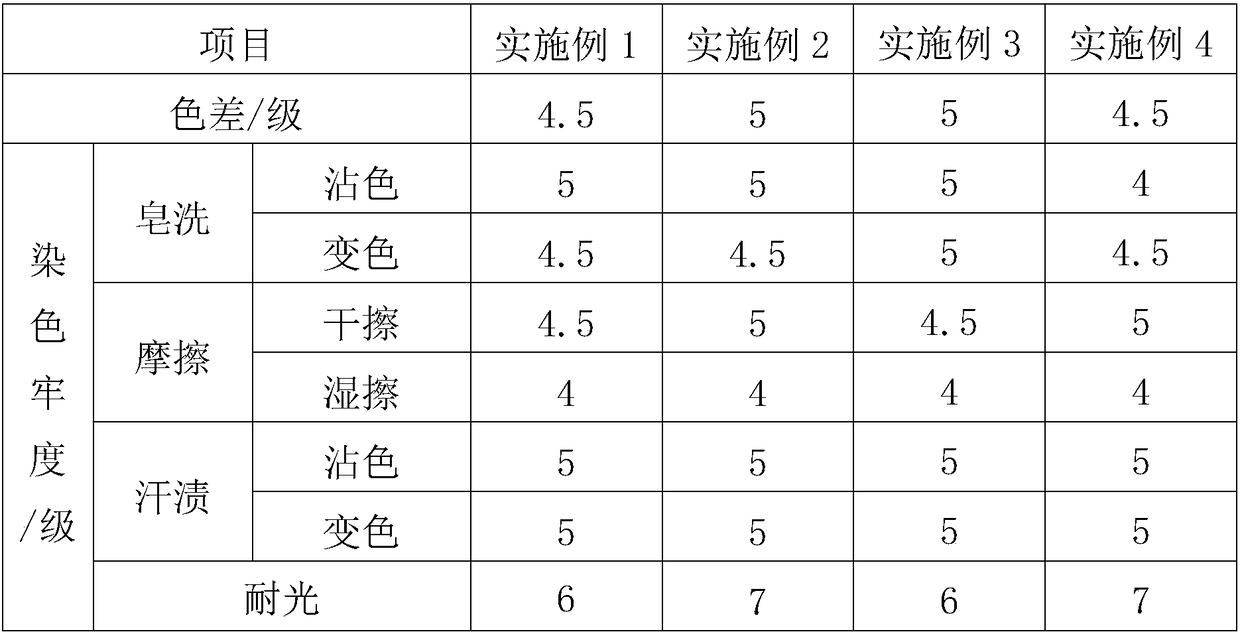

Examples

Embodiment 1

[0019] In the present embodiment, a kind of homochromatic dyeing process that contains chitin viscose fiber fabric comprises the steps:

[0020] S1, pretreatment, immerse the viscose fiber fabric containing chitin in isopropanol, add a sodium hydroxide solution with a content of 25 wt%, stir evenly, then add etherifying agent CTA, stir and react at 60°C for 2 hours, add hydrochloric acid After the pH is adjusted to 10-11, the solvent is drained, washed with water, and dried. The weight ratio of the viscose fiber fabric containing chitin, sodium hydroxide solution, and etherifying agent CTA is 1:0.01:0.1;

[0021] S2, Reactive dyeing, immerse the fabric obtained by S1 into the reactive dye solution, adjust the bath ratio to 1:10, heat up to the initial dyeing temperature of 60°C at a rate of 2°C / min and keep it warm for 10min, add acetone, acetone The volume ratio with the reactive dye solution is 1:3, heat up to the dyeing temperature at a rate of 0.5°C / min to 100°C and keep i...

Embodiment 2

[0024] In the present embodiment, a kind of homochromatic dyeing process that contains chitin viscose fiber fabric comprises the steps:

[0025] S1, pretreatment, immerse the viscose fiber fabric containing chitin in isopropanol, add sodium hydroxide solution with a content of 35wt%, stir evenly, then add etherification agent CTA, stir and react at 40°C for 4h, add hydrochloric acid After the pH is adjusted to 10-11, the solvent is drained, washed with water, and dried. The weight ratio of the viscose fiber fabric containing chitin, sodium hydroxide solution, and etherifying agent CTA is 1:0.5:0.01;

[0026] S2, active dyeing, immerse the fabric obtained through S1 treatment into the reactive dye solution, adjust the bath ratio to 1:5, heat up to the initial dyeing temperature of 40°C at a speed of 3°C / min and keep it warm for 30min, add hexanone, The volume ratio of hexanone and reactive dye liquor is 1:1, heat up to the dyeing temperature of 80°C at a rate of 1°C / min and kee...

Embodiment 3

[0029]In the present embodiment, a kind of homochromatic dyeing process that contains chitin viscose fiber fabric comprises the steps:

[0030] S1, pretreatment, immerse the viscose fiber fabric containing chitin in isopropanol, add a sodium hydroxide solution with a content of 30 wt%, stir evenly, then add etherifying agent CTA, stir and react at 50°C for 3h, add hydrochloric acid After the pH is adjusted to 10-11, the solvent is drained, washed with water, and dried. The weight ratio of the viscose fiber fabric containing chitin, sodium hydroxide solution, and etherifying agent CTA is 1:0.2:0.5;

[0031] S2, Reactive dyeing, immerse the fabric obtained by S1 treatment into the reactive dye solution, adjust the bath ratio to 1:7, raise the temperature to the initial dyeing temperature of 50°C at a speed of 2.5°C / min and keep it warm for 20min, add ethyl acetate , the volume ratio of ethyl acetate and reactive dye liquor is 1:2, heat up to the dyeing temperature of 90°C at a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com