Anti-loosening anti-theft nut

An anti-theft nut and anti-loosening technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of clumsy installation tools, restricting wide application and promotion, and not wearing gloves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

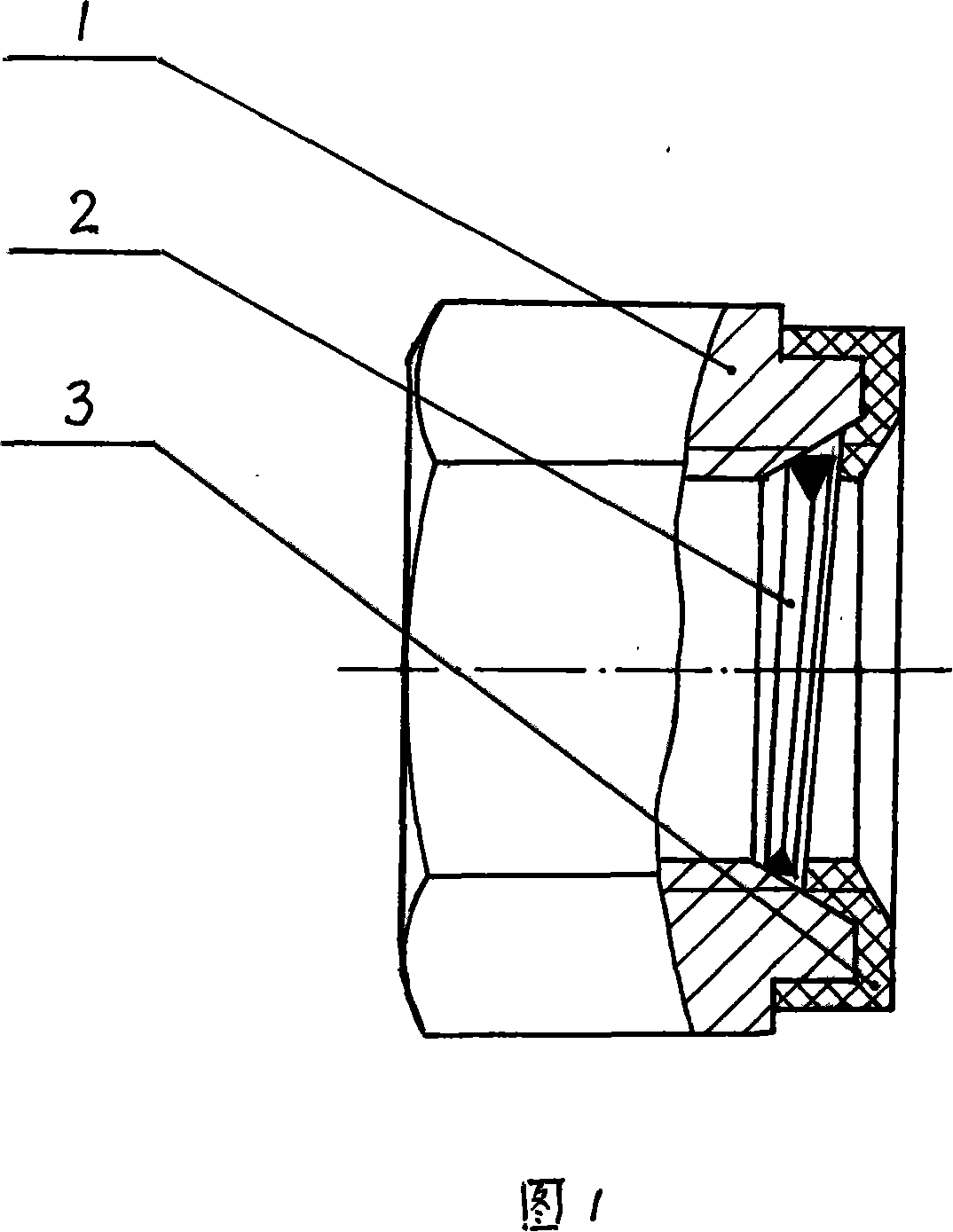

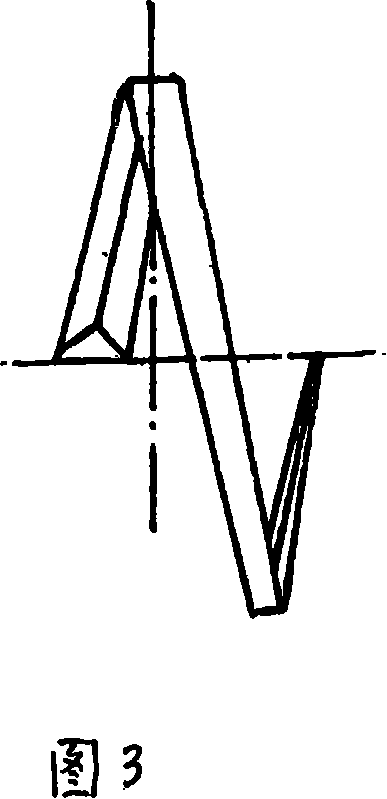

[0011] As shown in Fig. 1, the anti-loosening and anti-theft nut of the present invention is composed of a chamfered nut (1), a spiral wedge (2) and a thin-walled sleeve (3). The inner hole of the chamfered nut (1) is a through-through standard triangular internal thread, and the outer circle of the cylindrical boss at one end and the inner hole of the large end of the thin-walled sleeve (3) are interference fit, and the chamfered nut (1) The inner hole at the end of the cylindrical boss is chamfered to form a tapered surface of the inner hole. The spiral wedge (2) is compressed and fixed between the inner tapered surface and the spiral surface at the bottom of the thin-walled sleeve (3).

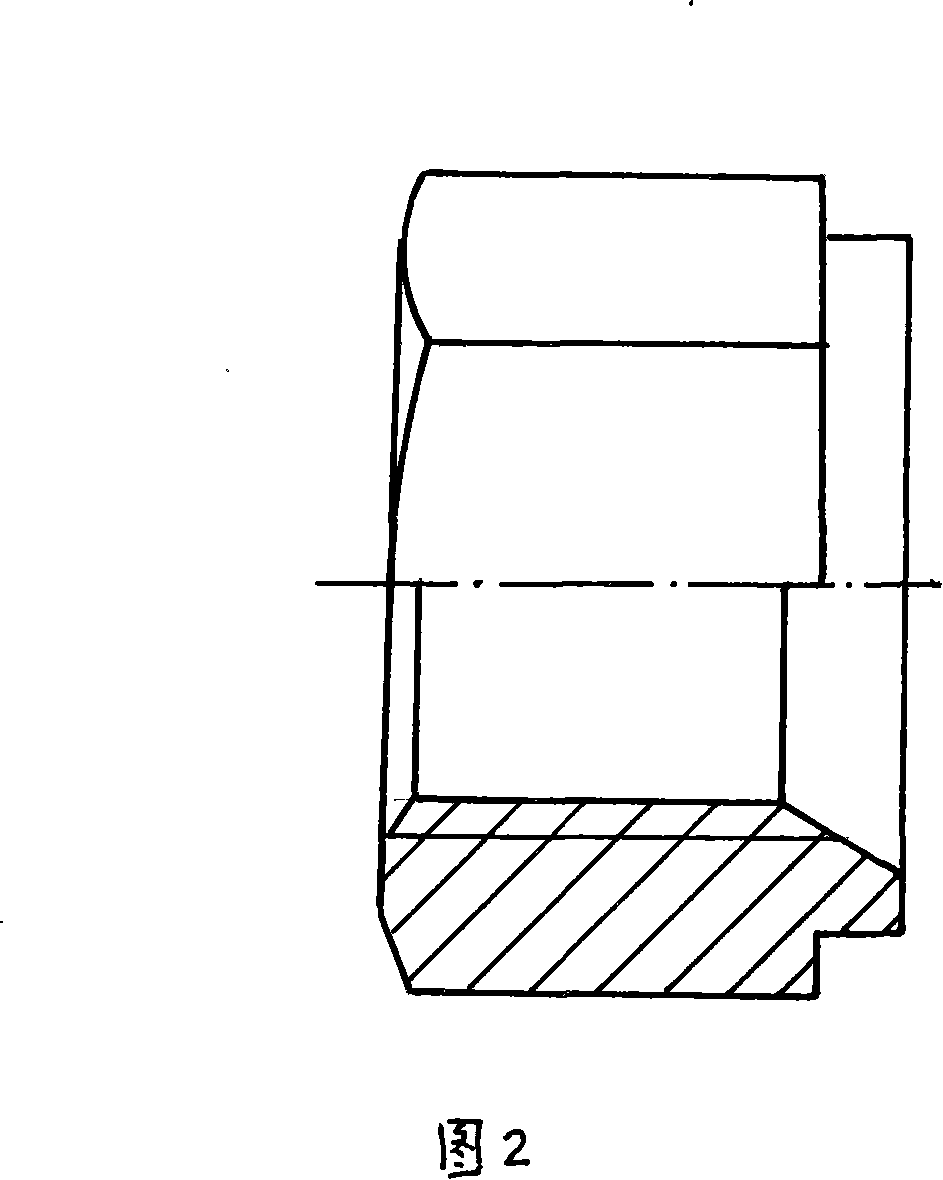

[0012] As shown in Figure 2, the body of the screw wedge locking anti-loosening and anti-theft nut of the present invention is a chamfered nut (1). Its shape is a standard hexagon, the inner hole is a standard triangular coarse thread, the outer surface of one end is a cylindrical boss, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com