Precision rotation positioning platform based on compliant mechanism

A technology of a compliant mechanism and a positioning platform, which is applied to the parts and instruments of the instrument, can solve the problems that the rigid rotating platform is difficult to meet the requirements, difficult to maintain, and expensive to build, and achieves good versatility and practical value, simple maintenance, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing of description:

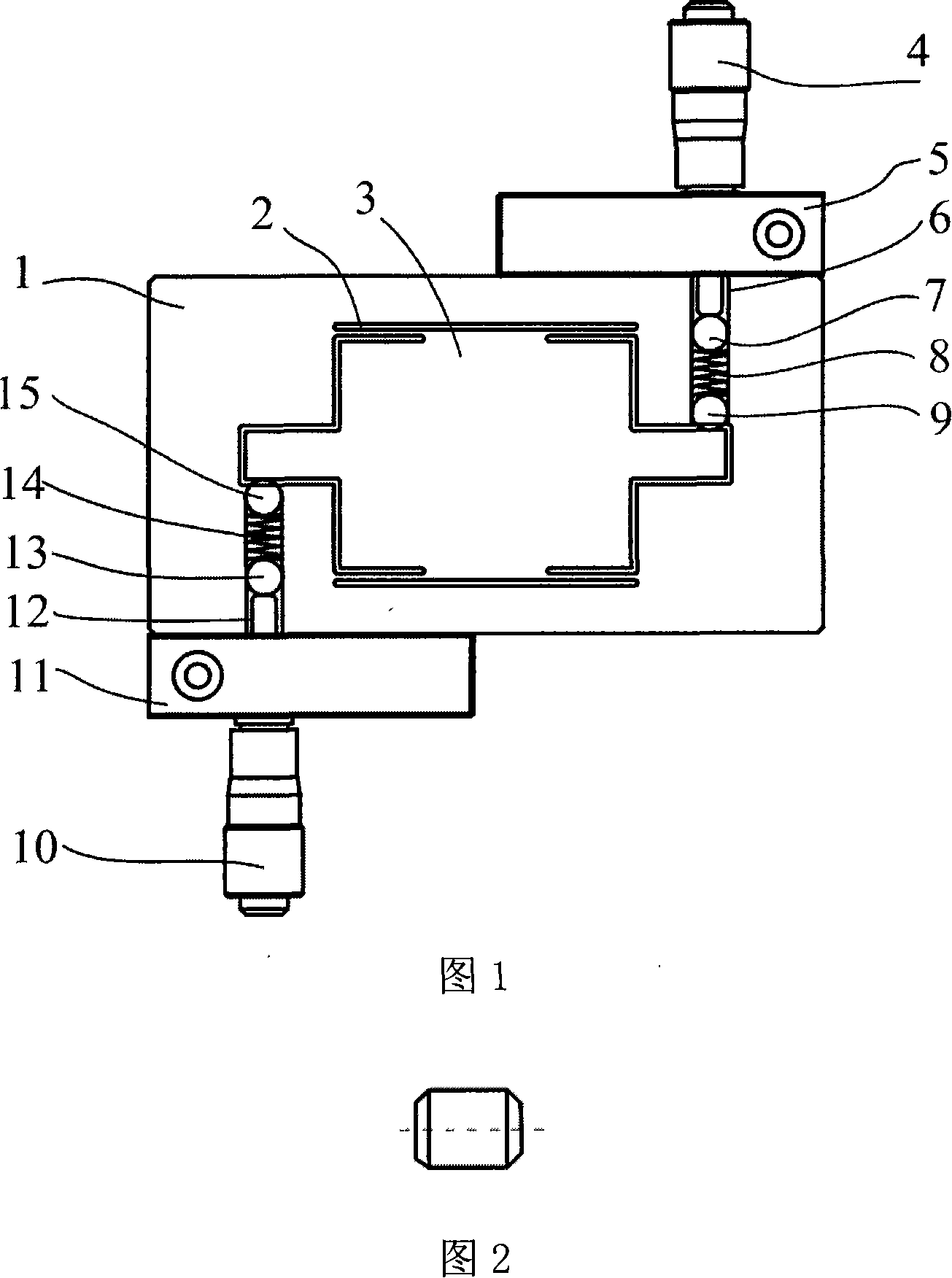

[0013] As shown in Figure 1, the precision rotary positioning platform based on the compliance mechanism includes a base 1, a motion platform 3, a guide mechanism 2 and two sets of driving devices. Among the two groups of driving devices, one group is composed of a telescopic brake 4, a fixing member 5, two balls 7, 9 and a spring 8; the other group is composed of a telescopic brake 10, a fixing member 11, two balls 13, 15 and a spring 14 composition. Two opposite sides of the base 1 are respectively provided with a round hole, such as the round hole 6 and the round hole 12 in the figure, which are used to install two groups of driving devices; the two groups of driving devices are distributed on the two opposite sides of the motion platform 3, and Misalignment distribution; in one group of driving devices, two balls 7, 9 and sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com