Flexible led array

A flexible substrate and heat dissipation pad technology, applied in the field of flexible LED arrays, can solve the problems of inability to achieve heat dissipation, large units, loss of flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

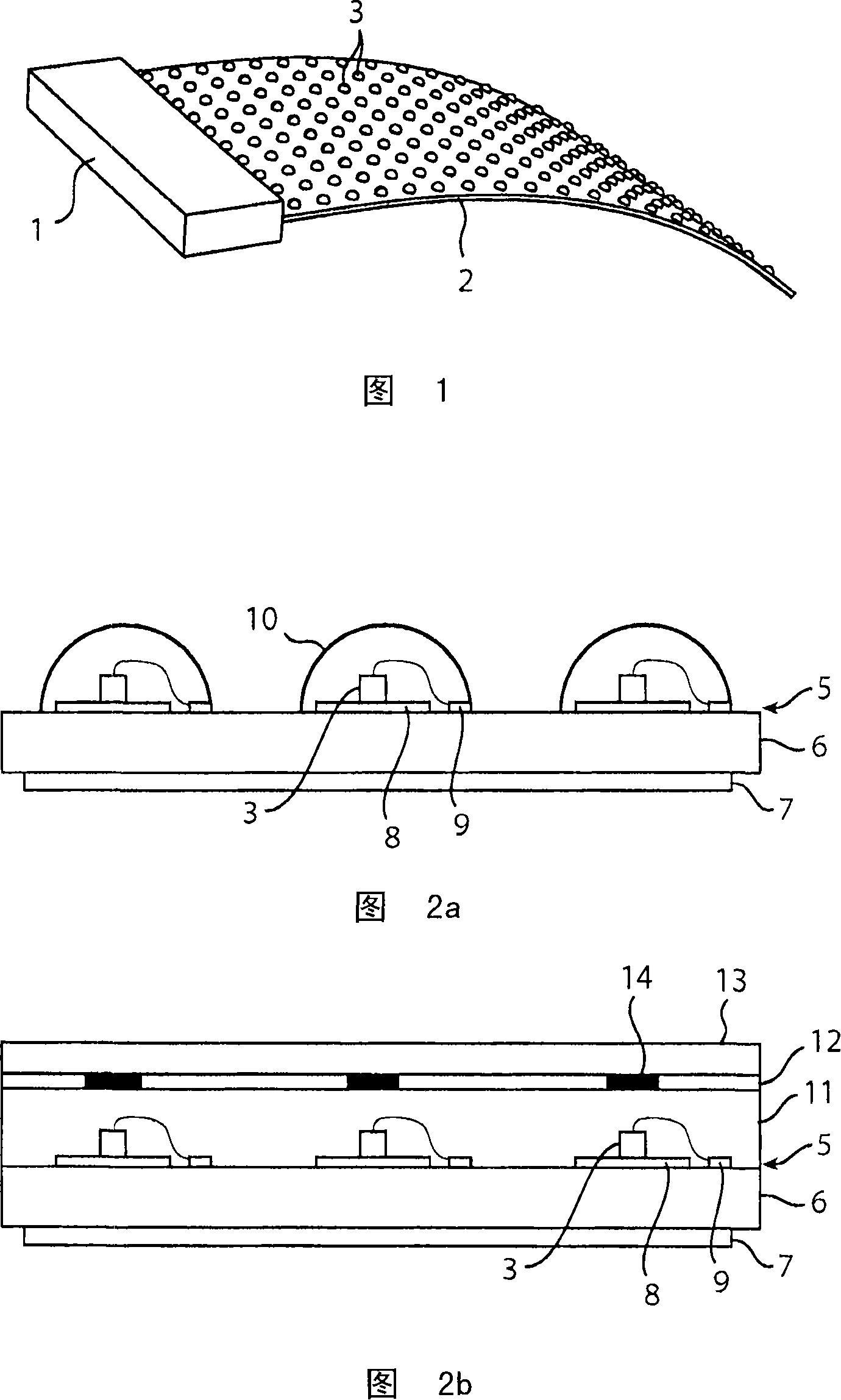

[0022] The light emitting device shown in Fig. 1 includes: a control unit 1, a flexible substrate 2, and a plurality of LEDs 3 arranged on the substrate. The control unit 1 contains any driver circuits, interfaces, connectors, etc. needed to connect the device to a power source and drive the LED to emit light. Since the control unit keeps all control circuits close to each other, the circuits are well protected. However, the control unit forming part of the flexible device is rigid.

[0023] As an alternative, the control circuits may be distributed on the substrate, for example along the sides of the substrate. This allows for a fully flexible device, but does not result in optimal physical protection of the components.

[0024] The power supply of the device can be conventional, with a connector or even with batteries contained in the control unit 1 . However, it may be beneficial to provide a power source that is not connected. For example, capacitive or inductive power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com