Redbeds mudstone filled high-speed railway subgrade and construction method thereof

A technology for red-bed mudstone and high-speed railway is applied in the field of railway subgrade and its construction to achieve the effects of filling quality control, protecting the environment and reducing spoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

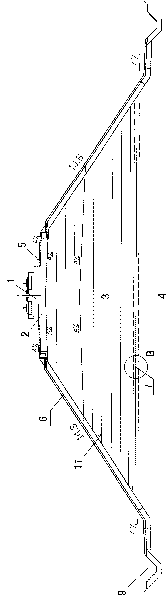

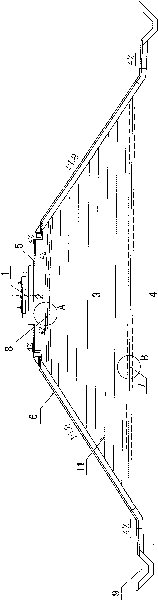

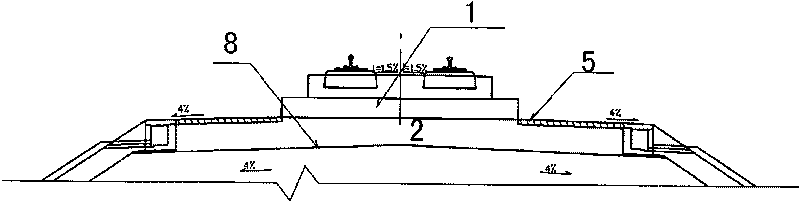

[0022] refer to figure 1 and figure 2 , the high-speed railway subgrade filled with red bed mudstone of the present invention has a trapezoidal cross section and is composed of a red bed mudstone filling layer 3, a subgrade bed 2, and a track concrete foundation 1 that are sequentially filled on the subgrade base 4. In order to make the subgrade have good stability, the height of the red bed mudstone fill layer 3 should be less than 8m, the slope form should be straight, and the slope ratio should be 1:1.8; according to the local rainfall characteristics, the road shoulders on both sides of the subgrade should 9 The standard subgrade should be wider by 0.6-1.0m. In order to increase the strength of the subgrade and reduce its deformation, the subgrade slope has a slope protection structure 6 and is reinforced by a slope reinforcement structure 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com